Hydrogen Supply Chain Optimization

TOP 20 HYDROGEN SUPPLY CHAIN OPTIMIZATION CASE STUDIES

Explore the Top 20 Hydrogen Supply Chain Optimization Now!

- What are the top 20 case studies of hydrogen supply chain optimization?

- What are the proven strategies and best practices highlighted in the top 20 hydrogen supply chain optimization case studies?

- What are the tangible results achieved by companies through hydrogen supply chain optimization?

- What are the untapped opportunities within hydrogen supply chain optimization?

- How can businesses learn from the top 20 hydrogen supply chain optimization case studies to identify and overcome potential missed opportunities, ensuring maximum potential is realized and staying ahead in the market?

Read More..

Hydrogen supply chain optimization is the process of designing and managing the various activities involved in the production, transportation, storage, and distribution of hydrogen in the most efficient and cost-effective way possible. Optimization is achieved by identifying and addressing the inefficiencies, bottlenecks, and other constraints that may impede the smooth flow of hydrogen throughout the supply chain.

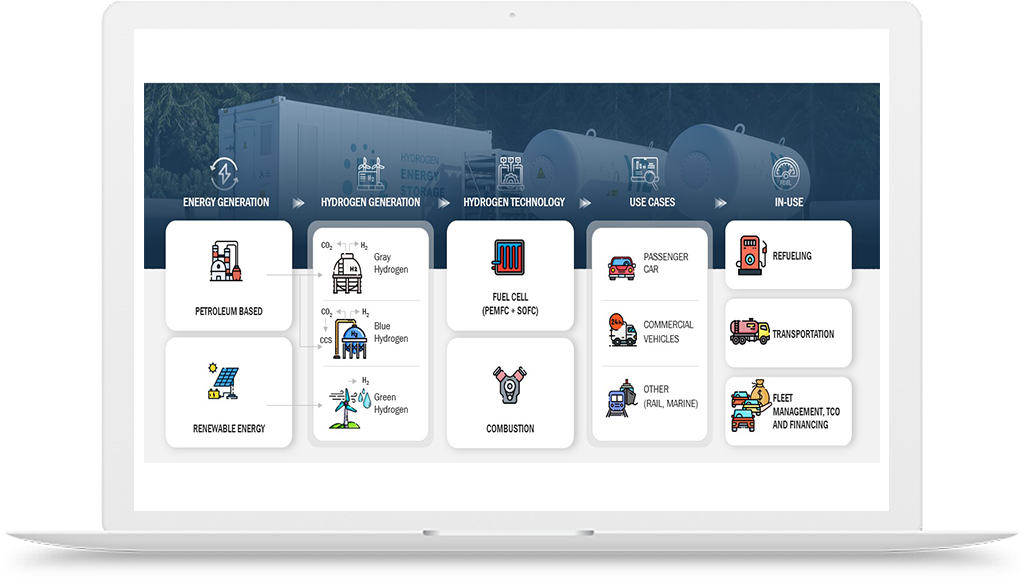

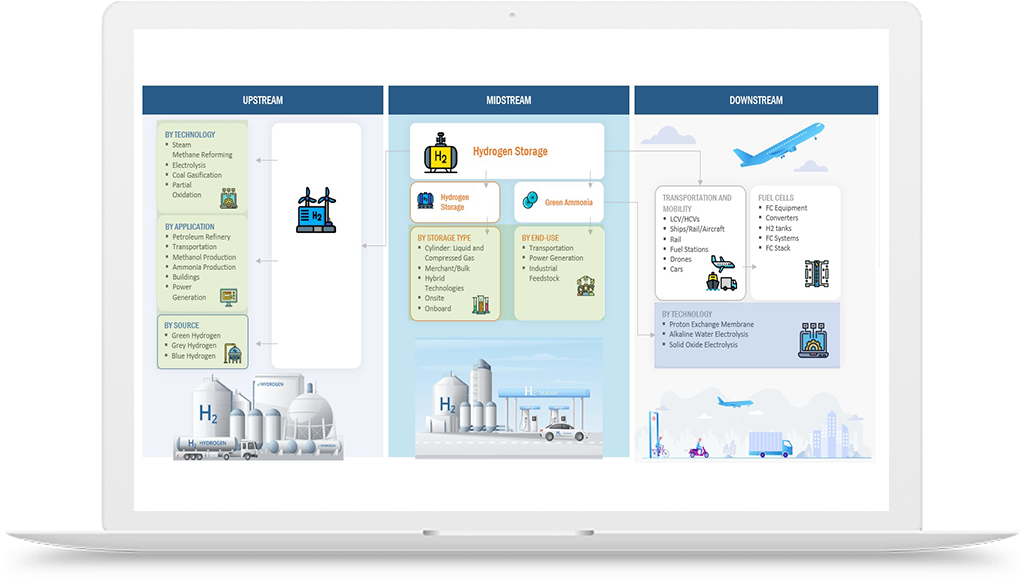

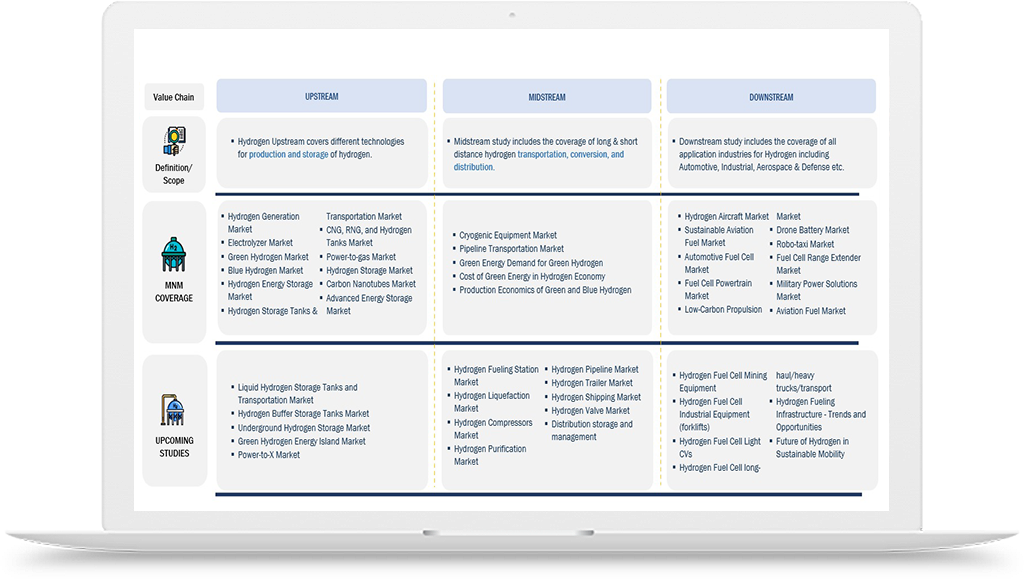

The hydrogen supply chain optimization consists of several stages, each of which presents unique challenges and opportunities. These stages include:

- Production: Hydrogen can be produced from various sources such as natural gas, biomass, and water through different processes such as steam methane reforming, electrolysis, and biomass gasification. The choice of production method depends on the availability and cost of feedstock, energy source, and other factors. Optimizing hydrogen production involves selecting the most suitable and sustainable feedstock and energy source, optimizing the production process, and minimizing the production cost.

- Storage and Transportation: : Usually, hydrogen is transported and stored in liquid or gaseous form. The volume and separation between the hydrogen supply and demand points, in addition to the necessary purity and pressure, determine which storage and transportation method is best. The best possible method of storage and transportation must be chosen, the storage and transportation procedure must be optimized, and the cost of storage and transportation must be kept to a minimum in order to optimize hydrogen storage and transportation.

- Distribution: Pipelines, trucks, or ships carry hydrogen to the final consumers, which include fuel cell cars, industrial uses, and electricity production. The volume and location of the end users, together with the necessary purity and pressure, all influence the distribution method selection. The process of optimizing hydrogen distribution entails determining the best distribution strategy, streamlining the distribution procedure, and reducing distribution expenses.

In conclusion, every hydrogen technology has pros and cons, and the decision about which to use is influenced by a number of variables, such as infrastructure and feedstock availability, cost, efficiency, and environmental impact.

Several tools and techniques can be used for hydrogen supply chain optimization, including:

- Supply Chain Modeling: The process of digitally representing the supply chain, with all of its nodes, stages, and flows included, is known as supply chain modeling. The model can be used to test the effects of various parameters, including cost, efficiency, and environmental impact, on the performance of the supply chain and to simulate different scenarios.

- Real-Time Monitoring: Real-time monitoring entails keeping an eye on the various phases of the hydrogen supply chain in real-time using sensors, data analytics, and other tools. In order to take corrective action and identify inefficiencies, bottlenecks, and other constraints that may affect the performance of the supply chain, data collection can be used.

- Automation: Automation is the process of automating the production, storage, distribution, and transportation of hydrogen through the use of robotics, artificial intelligence, and other technologies. Automation can help lower labor costs, boost productivity, and enhance supply chain security.

Optimizing the hydrogen supply chain is essential to the development and prosperity of the hydrogen economy. Hydrogen can be purchased for less money, more efficiently, and with less of an impact on the environment if the supply chain is optimized. The process of optimizing the hydrogen supply chain is intricate and ever-changing, necessitating cooperation and coordination between producers, distributors, end users, regulators, and lawmakers.

Hydrogen supply chain optimization refers to the strategic and systematic management of the processes, resources, and logistics involved in the production, storage, transportation, and distribution of hydrogen. It aims to maximize efficiency, reduce costs, minimize waste, and improve overall performance throughout the hydrogen value chain.

The hydrogen supply chain encompasses various stages, including hydrogen production, purification, compression, storage, transportation, and delivery to end-users. Each stage involves specific activities, infrastructure, and logistical considerations that can be optimized to achieve a well-coordinated and efficient supply chain.The hydrogen supply chain encompasses various stages, including hydrogen production, purification, compression, storage, transportation, and delivery to end-users. Each stage involves specific activities, infrastructure, and logistical considerations that can be optimized to achieve a well-coordinated and efficient supply chain.

hydrogen supply chainThe hydrogen supply chain involves the processes and infrastructure associated with the production, storage, transportation, and distribution of hydrogen. It plays a critical role in supporting various applications, including industrial processes, transportation, and energy storage. Here are the key components of the hydrogen supply chain:

Optimizing the hydrogen supply chain involves several key elements:

- Production Optimization: This is centered on optimizing the effectiveness of techniques for producing hydrogen, such as electrolysis, biomass gasification, steam methane reforming, or other cutting-edge technologies. It entails cutting production costs, raising catalyst performance, increasing energy efficiency, and optimizing process parameters. In order to produce green hydrogen, production optimization also takes into account the integration of renewable energy sources.

- Storage Optimization: Hydrogen storage must be done well in order to meet demand variations and guarantee a steady supply. The process of optimizing storage involves the choice of suitable technologies, such as cryogenic liquid or compressed gas storage, and the adjustment of storage capacities in accordance with demand trends. In order to improve safety and economy, it also entails reducing hydrogen loss during storage and creating creative storage solutions.

- Transportation Optimization: The safe, economical, and efficient transportation of hydrogen must be carefully considered. Optimization is the process of determining which modes of transportation—pipelines, trucks, or shipping—are best for a given distance, volume, and infrastructure availability. It also entails maximizing transportation routes, taking into account elements like infrastructure accessibility, hydrogen purity requirements, and minimizing emissions associated with transportation.

- Infrastructure Optimization: The infrastructure supporting the hydrogen supply chain needs to be strategically planned and optimized. This includes designing and developing production facilities, storage terminals, refueling stations, and distribution networks in a way that minimizes costs, maximizes accessibility, and ensures scalability. Infrastructure optimization also considers the integration of existing infrastructure, such as repurposing natural gas pipelines for hydrogen transportation.

- Demand-Supply Balancing: Effective supply chain optimization entails maintaining a balance between the supply and demand of hydrogen in order to guarantee dependability and prevent surplus or underutilization. Precise demand forecasting, the creation of end-user communication and coordination channels, and the application of supply chain disruption and demand fluctuation management techniques are all necessary for this.

- Collaboration and Integration: Supply chain optimization requires collaboration and integration among various stakeholders involved in the hydrogen value chain, including producers, storage operators, transporters, and end-users. Collaboration ensures the smooth flow of information, coordinated decision-making, and joint efforts to address challenges and improve efficiency. Integration of different supply chain elements and technologies promotes seamless operations and reduces inefficiencies.

- Data Analytics and Technology: The use of advanced analytics, data-driven decision-making, and digital technologies play a crucial role in optimizing the hydrogen supply chain. These tools enable real-time monitoring, predictive maintenance, inventory management, and optimization of operational processes. By leveraging data analytics and technology, stakeholders can identify optimization opportunities, improve asset utilization, and enhance overall supply chain performance.

Green hydrogen supply chain

The production, storage, transportation, and use of hydrogen generated by the electrolysis process—which employs renewable energy sources like solar, wind, or hydropower—are all included in the green hydrogen supply chain. Since green hydrogen doesn't produce carbon emissions like traditional hydrogen production methods like steam methane reforming (SMR), it is regarded as environmentally friendly.

The establishment of an effective green hydrogen supply chain is crucial for tackling global energy issues, achieving sustainability objectives, and facilitating the shift to a low-carbon economy. The following are some of the main arguments in favor of the importance of an effective green hydrogen supply chain:

Significance of Efficient Green Hydrogen Supply Chain Management

- Carbon Emission Reduction: Green hydrogen is a carbon-free or low-carbon substitute for traditional hydrogen production techniques because it is made using renewable energy sources. Climate change can be lessened by reducing total carbon emissions, which is accomplished through an effective green hydrogen supply chain.

- Renewable Energy Integration: An option for storing extra electricity produced by sporadic renewable energy sources like solar and wind is provided by green hydrogen production. It makes it possible to incorporate renewable energy sources into the system as a whole, assisting in resolving the issue of intermittency and variability.

- Decarbonization of Industrial Processes: Steel, petrochemicals, and refining are just a few of the industrial processes that use green hydrogen as a clean feedstock. By being used in these sectors, it helps traditionally carbon-intensive industries become less carbon-intensive.

- Clean Transportation: Fuel cell vehicles (FCVs) and other hydrogen-powered vehicles are growing because of an effective green hydrogen supply chain. For the transportation sector to reduce emissions, this is essential.

- Energy Storage and Grid Balancing: Grid balancing, and energy storage are two applications for green hydrogen. Excess renewable energy can be electrolyzed to create hydrogen during times of low energy demand. Hydrogen can then be stored and used to generate electricity during times of peak demand.

- Job Creation and Economic Growth: The establishment and management of a green hydrogen supply chain boosts employment and the economy. Jobs in electrolysis technology, infrastructure development for hydrogen, and related services are included in this.

- Global Energy Security: By diversifying energy sources, green hydrogen helps lessen reliance on conventional fossil fuels. By building a more resilient and sustainable energy system, this diversification improves energy security.

Green hydrogen demand

Green hydrogen demand has been growing steadily, driven by various factors related to environmental sustainability, government policies, and the global transition toward clean energy.

The green hydrogen demand incorporates a range of parties and procedures at every stage of the process, from manufacturing to final applications.

Key Stakeholders and Processes Involved in Green hydrogen demand

Here are key stakeholders and processes involved in the green hydrogen demand:

- Energy Producers and Project Developers: Businesses engaged in the construction and management of renewable energy projects, like wind and solar farms, supply the green electricity required for electrolysis.

- Hydrogen Producers: Businesses that specialize in using electrolysis to produce green hydrogen. They own and run facilities for producing hydrogen using renewable energy sources.

- Technology Providers: Systems and equipment required for the electrolysis process in the production of green hydrogen are supplied by manufacturers and developers of electrolysis technologies.

- Infrastructure Developers: Organizations engaged in building pipelines, storage facilities, and transportation networks as well as other infrastructure for the distribution, storage, and transit of green hydrogen.

- Industrial Consumers: As they work to decarbonize their operations, sectors with high energy demands, like steel, chemicals, and refining, are major users of green hydrogen.

- Transportation Sector: Companies operating fleets of vehicles, such as buses, trucks, and ships, may contribute to the demand for green hydrogen as a clean fuel for transportation.

- End-User Sectors: Power generating companies can use green hydrogen in fuel cells to generate electricity or balance the grid.

- Research Institutions and Technology Developers: The field of green hydrogen technologies is being driven by innovation and its understanding is being advanced by academic institutions and research organizations.

- Financial Institutions and Investors: Financial institutions and investors provide funding, capital, and financial support for the development and expansion of the hydrogen supply chain. They play a crucial role in financing infrastructure projects, production facilities, storage terminals, and transportation networks. Their involvement is essential for scaling up the hydrogen industry.

- Collaborative Platforms and Industry Associations: Collaborative platforms and industry associations bring together stakeholders from different sectors of the hydrogen supply chain. They facilitate knowledge sharing, promote collaboration, and advocate for supportive policies and regulations. These platforms contribute to the overall growth and development of the hydrogen industry.

Hydrogen energy supply chain

The process of producing, moving, storing, and using hydrogen as a fuel is all included in the hydrogen energy supply chain. Because of its versatility and ability to be produced in a variety of ways, hydrogen finds application in a wide range of fields, including power generation, transportation, and industry.Although hydrogen has the potential to be a major player in the low-carbon energy transition, a number of issues with the hydrogen energy supply chain must be resolved before it can be widely adopted.

Here's an overview of the key Challenges of the hydrogen energy supply chain.

- Production Costs: Hydrogen production is currently more expensive than steam methane reforming, especially when using techniques like electrolysis. Hydrogen needs to be made more economically competitive by lowering its production costs.

- Energy Intensity: The process of producing hydrogen, especially through electrolysis, requires a lot of energy. The environmental advantages of hydrogen may be offset if fossil fuels are used to generate the electricity needed for the process. To guarantee a low carbon footprint, hydrogen production must make use of renewable energy sources.

- Storage and Transportation: Because of its low energy density per unit of volume, hydrogen can be difficult to store and move. For hydrogen to be widely used, it is imperative that efficient and affordable storage and transportation methods, such as pipelines, trucks, and ships, be developed.

- Safety Considerations: Hydrogen is highly flammable and requires strict safety protocols throughout the supply chain. Safety considerations include preventing leaks, managing the risk of explosions or fires, and ensuring the safe handling and transportation of hydrogen. Public perception and acceptance of hydrogen safety are also critical factors that need to be addressed to build trust and confidence in the hydrogen supply chain.

- Infrastructure Development: There isn't much infrastructure in place right now to produce, distribute, and use hydrogen. To support a growing hydrogen economy, a strong infrastructure of pipelines, refueling stations, and storage facilities must be developed and expanded.

- Carbon Capture and Storage (CCS): Carbon capture and storage can reduce the carbon emissions associated with hydrogen produced by processes such as steam methane reforming. Nevertheless, in order to lessen the environmental impact of hydrogen production, CCS technologies still require development and implementation.

- Scale-Up Challenges: Currently, the market for hydrogen is tiny in comparison to other energy sources. Governments, businesses, and academic institutions will need to make large investments and work together to reduce costs and achieve economies of scale.

- Technological Advancements: To increase the effectiveness of fuel cell technologies, storage technologies, and processes for producing hydrogen, more research and development are required. The entire hydrogen value chain depends on advances in materials science and engineering.

- Public Perception and Acceptance: There may be obstacles in the form of public acceptance and awareness of hydrogen technologies, especially in applications such as fuel cell vehicles. Creating awareness, addressing safety issues, and highlighting the advantages of hydrogen are crucial to winning over the general public.

Hydrogen demand

Many tactics can be used to encourage and supply the increasing hydrogen demand. These tactics include tackling the market's supply and demand for hydrogen as well as fostering an atmosphere that will encourage the development of technologies related to hydrogen.

Here are some key strategies for the Hydrogen demand.

- Policy Support and Incentives: To promote the production and use of hydrogen, governments can play a significant role by putting supportive policies and incentives in place, such as grants, tax credits, and subsidies.

- Research and Development: To advance hydrogen production, storage, and transportation technologies, allocate resources to research and development. This covers developments in fuel cell efficiency, electrolysis, and materials for hydrogen infrastructure.

- Infrastructure Development: Develop a robust infrastructure for hydrogen production, distribution, and refueling. This includes establishing hydrogen refueling stations for vehicles and ensuring a network of pipelines for industrial use.

- International Collaboration: Work together with foreign nations and organizations to establish a worldwide market for hydrogen. To facilitate cross-border trade, this includes setting uniform standards for the production and transportation of hydrogen.

- Integration with Renewable Energy: Promote the fusion of renewable energy sources and hydrogen production. This addresses the intermittent nature of renewable energy generation by employing surplus electricity from renewable sources for the electrolysis process that yields hydrogen.

- Industrial Integration: Promote the integration of hydrogen into industrial processes, such as the production of chemicals and refining. Incentivize industries to adopt hydrogen as a feedstock, thereby increasing demand.

- Hydrogen in Transportation: Encourage the use of hydrogen fuel cell cars in heavy-duty trucks, public transportation, and other industries where electrification might be difficult.

- Policy Support and Market Development: Establishing supportive policies and creating a favorable market environment are essential for supply chain optimization. Policymakers should provide long-term policy stability, set ambitious renewable energy and emission reduction targets, and implement supportive regulations. This can stimulate investment, incentivize innovation, and create a strong market demand for hydrogen, driving supply chain optimization efforts.

- Collaboration and Knowledge Sharing: Collaboration among stakeholders is crucial for supply chain optimization. Creating collaborative platforms, industry partnerships, and knowledge-sharing networks can foster information exchange, best practice sharing, and joint research and development efforts. By leveraging collective expertise, stakeholders can identify optimization opportunities, address challenges, and drive innovation in the hydrogen supply chain.

Key Technologies for Hydrogen Supply Chain Optimization

Several key technologies play a significant role in optimizing the hydrogen supply chain. These technologies enhance the efficiency, reliability, and cost-effectiveness of hydrogen production, storage, transportation, and distribution. Here are some key technologies for hydrogen supply chain optimization:

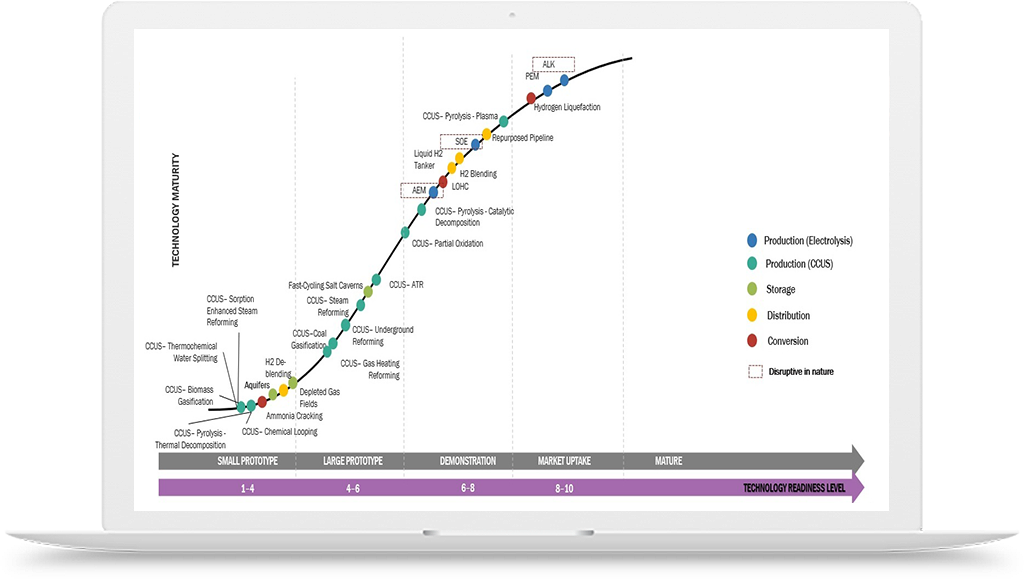

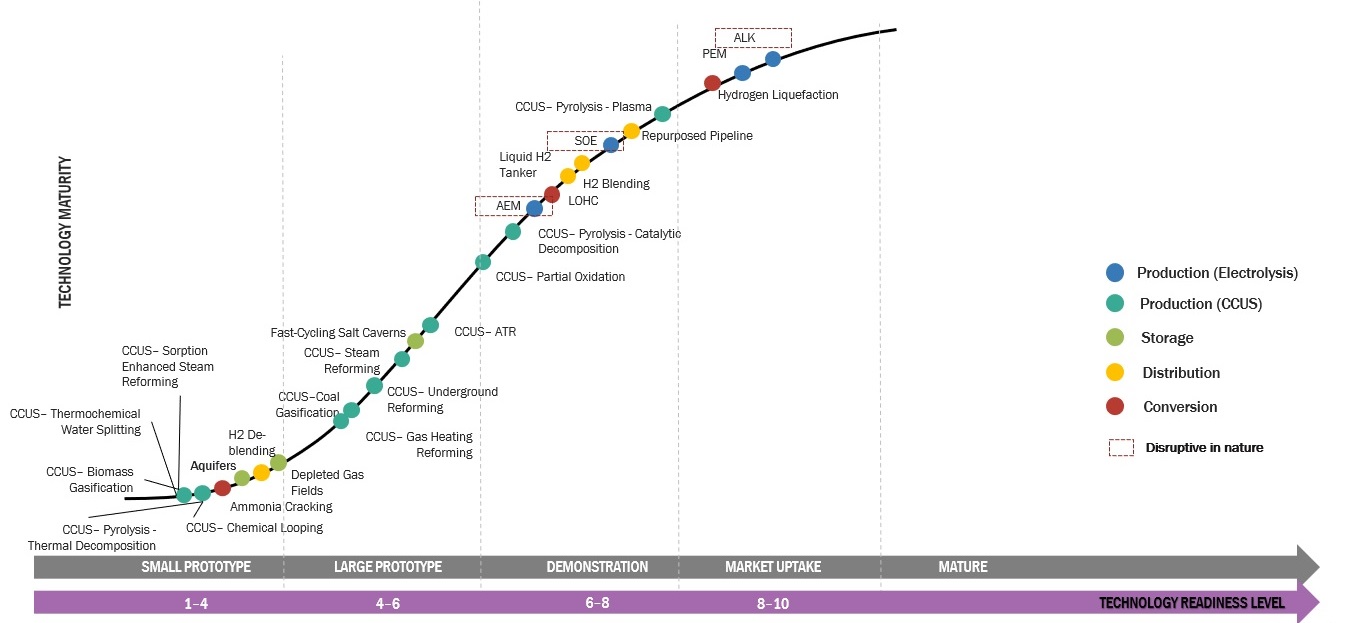

- Advanced Electrolysis: Electrolysis is a key technology for producing hydrogen from water, particularly through the use of renewable electricity. Advancements in electrolysis technology, such as proton exchange membrane (PEM) electrolysis and solid oxide electrolysis cells (SOEC), enable efficient hydrogen production with improved energy conversion efficiency and reduced capital costs. These advanced electrolysis technologies help optimize the production phase of the supply chain by increasing the flexibility and scalability of hydrogen production.

- Advanced Compression and Storage Systems: Effective compression and storage technologies are crucial for optimizing the storage phase of the hydrogen supply chain. Advanced compression systems, such as advanced compressors and multi-stage compression, improve energy efficiency and reduce compression losses during hydrogen transportation and storage. Innovative storage systems, including high-pressure cylinders, cryogenic liquid storage, and solid-state storage materials, enable higher storage capacity, improved safety, and reduced hydrogen losses.

- Hydrogen Pipeline Infrastructure: Developing dedicated hydrogen pipeline infrastructure is a key technology for optimizing the transportation phase of the supply chain. Hydrogen pipelines enable the efficient and reliable transfer of large volumes of hydrogen over long distances. Advancements in pipeline materials, coatings, and integrity monitoring systems enhance the safety, durability, and efficiency of hydrogen transportation, reducing leakage and energy losses.

- Hydrogen Liquefaction and Dehydration: Liquefaction of hydrogen offers higher energy density, enabling more efficient transportation and storage. Technologies for hydrogen liquefaction, such as cryogenic processes and advanced refrigeration systems, optimize the transportation phase by reducing the volume and energy requirements for hydrogen transportation. Dehydration technologies remove moisture from hydrogen, improving its purity and reducing the risk of pipeline corrosion.

- Hydrogen Refueling Infrastructure: To optimize the distribution phase of the supply chain, the development of efficient and scalable hydrogen refueling infrastructure is essential. This includes hydrogen refueling stations for fuel cell vehicles, industrial hydrogen distribution systems, and decentralized hydrogen distribution networks. Technologies such as fast-fill and slow-fill dispensing systems, hydrogen purification units, and advanced safety systems contribute to the optimization of hydrogen distribution and refueling.

- Smart Grid and Energy Management Systems: Integrating hydrogen supply chain operations with smart grid technologies and advanced energy management systems can optimize the overall system performance. This allows for real-time monitoring, demand response, load balancing, and efficient integration of renewable energy sources. Smart grid technologies help manage the intermittent nature of renewable energy and enable the effective utilization of excess electricity for hydrogen production or power-to-gas applications.

- Internet of Things (IoT) and Data Analytics: The use of IoT devices and data analytics platforms can provide real-time monitoring and optimization of the hydrogen supply chain. Sensors, connected devices, and data analytics algorithms enable predictive maintenance, fault detection, energy optimization, and supply-demand balancing. These technologies enhance the efficiency and reliability of hydrogen production, storage, transportation, and distribution processes.

- Digital Platforms and Blockchain: Digital platforms and blockchain technology can improve transparency, traceability, and trust within the hydrogen supply chain. Blockchain enables secure and immutable record-keeping of transactions, certifications, and quality control throughout the supply chain. Digital platforms facilitate supply chain management, collaboration, and optimization, allowing stakeholders to access real-time data, monitor performance, and streamline operations.

Successful Hydrogen Supply Chain Optimization Examples

There are several successful examples of hydrogen supply chain optimization that highlight the feasibility and benefits of implementing efficient hydrogen supply chain systems. Here are a few notable examples:

- H2Haul Project (Europe): The H2Haul project, funded by the European Union, aims to optimize the supply chain for hydrogen fuel cell trucks. The project focuses on developing a comprehensive hydrogen refueling infrastructure along major European road corridors. By strategically locating hydrogen refueling stations and optimizing their capacity, H2Haul aims to support the widespread adoption of hydrogen trucks and optimize the supply chain for their refueling needs.

- HyStorPor Project (Spain): The HyStorPor project in Spain focuses on optimizing the storage and transportation of hydrogen. It involves the construction of an underground hydrogen storage facility and the development of a dedicated hydrogen pipeline infrastructure. By integrating these storage and transportation systems, the project aims to optimize the hydrogen supply chain, enabling the reliable and efficient delivery of hydrogen to end-users, including industrial applications and fuel cell vehicles.

- H2USA Partnership (United States): H2USA is a public-private partnership in the United States aimed at advancing the commercialization and deployment of hydrogen and fuel cell technologies. The partnership brings together stakeholders from government, industry, and academia to address the key challenges in the hydrogen supply chain. By fostering collaboration and sharing best practices, H2USA promotes supply chain optimization and supports the growth of hydrogen infrastructure and applications across various sectors.

- HyNet Project (United Kingdom): The HyNet project in the United Kingdom aims to create a low-carbon hydrogen supply chain for the North West of England. The project focuses on integrating hydrogen production from natural gas with carbon capture and storage (CCS) technology to significantly reduce carbon emissions. By optimizing the production, storage, and distribution of low-carbon hydrogen, HyNet aims to decarbonize industries, power generation, and transportation sectors in the region.

- HyTunnel-CS Project (Japan): The HyTunnel-CS project in Japan focuses on the optimization of hydrogen supply chain for fuel cell vehicles in tunnels. It involves the construction of hydrogen production, storage, and refueling facilities near tunnels to provide a safe and efficient refueling infrastructure. By addressing the unique challenges of refueling in tunnels, the project demonstrates the feasibility of hydrogen supply chain optimization for specific applications and environments.

Recent Technological Developments and Innovations Hydrogen Supply Chain Optimization

Recent years have witnessed significant technological developments and innovations aimed at optimizing the hydrogen supply chain. These advancements focus on enhancing the efficiency, reliability, and sustainability of hydrogen production, storage, transportation, and distribution. Here are some notable recent technological developments and innovations in hydrogen supply chain optimization:

- Hydrogen Pipeline Inspection Robots: Inspection robots equipped with advanced sensing technologies have been developed to monitor the integrity of hydrogen pipelines. These robots can detect and locate leaks, assess pipeline conditions, and perform maintenance tasks. By ensuring the safety and reliability of hydrogen transportation infrastructure, these robots contribute to the optimization of the supply chain.

- Advanced Hydrogen Storage Materials: Researchers are exploring advanced storage materials to improve the volumetric and gravimetric density of hydrogen storage. Materials such as metal-organic frameworks (MOFs), porous polymers, and nanostructured materials offer high surface areas and tailored hydrogen adsorption properties. These advancements enable more efficient and compact hydrogen storage, optimizing the storage phase of the supply chain.

- Hydrogen Supply Chain Digitalization: Digital technologies, including artificial intelligence (AI), Internet of Things (IoT), and big data analytics, are being employed to optimize various aspects of the hydrogen supply chain. These technologies enable real-time monitoring, predictive maintenance, demand forecasting, and optimization of production, storage, and distribution processes. Digitalization enhances supply chain efficiency, reduces costs, and improves overall performance.

- Hydrogen Fueling Infrastructure Innovations: Innovations in hydrogen fueling infrastructure aim to optimize refueling processes for fuel cell vehicles. Fast-fill and high-pressure hydrogen dispensing systems allow for quick refueling times, improving the convenience and adoption of hydrogen-powered vehicles. Additionally, advancements in hydrogen purification technologies ensure the delivery of high-purity hydrogen to fuel cell vehicles, optimizing the distribution phase of the supply chain.

- Renewable Hydrogen Production Technologies: The development of renewable hydrogen production technologies is a key focus area for supply chain optimization. Electrolyzers powered by renewable energy sources, such as wind and solar, are becoming more efficient and cost-effective. These technologies enable the production of "green" hydrogen, which has a lower carbon footprint and supports the decarbonization of the supply chain.

- Hydrogen Blending and Grid Injection: Hydrogen blending into existing natural gas pipelines and injecting hydrogen into the grid is being explored as a means to optimize the supply chain and integrate hydrogen into existing infrastructure. Research and pilot projects are underway to assess the feasibility, safety, and compatibility of hydrogen blending and grid injection, which can provide a pathway for utilizing excess renewable hydrogen and optimizing its distribution.

- Hydrogen Logistics Optimization: Advanced optimization algorithms and modeling techniques are being applied to optimize hydrogen logistics and supply chain planning. These technologies consider factors such as production capacity, transportation routes, storage capacities, demand patterns, and cost constraints to determine the most efficient and cost-effective supply chain configurations. Optimization tools help stakeholders make informed decisions and improve overall supply chain performance.

Future Outlook and Emerging Trends in Hydrogen Supply Chain Optimization

The future outlook for hydrogen supply chain optimization is promising, driven by the increasing recognition of hydrogen as a critical component in the transition to a low-carbon economy. Several emerging trends are shaping the future of hydrogen supply chain optimization:

- Scaling up Hydrogen Production: There is a growing focus on scaling up hydrogen production capacities to meet the rising demand. This includes the development of large-scale electrolysis projects, advanced steam methane reforming (SMR) facilities with carbon capture and storage (CCS), and the exploration of new pathways for sustainable hydrogen production, such as biomass gasification and solar-driven processes. Scaling up production will optimize the supply chain by ensuring a reliable and sufficient hydrogen supply.

- Integration of Renewables and Power-to-Gas: The integration of renewable energy sources and power-to-gas technologies will play a crucial role in optimizing the hydrogen supply chain. By coupling hydrogen production with intermittent renewable energy sources through electrolysis or other technologies, excess renewable energy can be stored as hydrogen and injected into the grid or utilized for transportation and industrial applications. This integration improves the efficiency, flexibility, and sustainability of the supply chain.

- Advancements in Hydrogen Storage and Transportation: Future developments in hydrogen storage and transportation technologies will optimize the logistics of the supply chain. Innovations in materials science, such as advanced hydrogen storage materials, solid-state hydrogen carriers, and cryogenic storage systems, will enhance the volumetric and gravimetric density of hydrogen storage, enabling more efficient transportation and distribution. Additionally, advancements in hydrogen pipeline infrastructure, compression technologies, and novel transportation modes will contribute to the optimization of the supply chain.

- Hydrogen Hubs and Regional Networks: The establishment of hydrogen hubs and regional networks is gaining momentum. These hubs integrate various components of the supply chain, including production, storage, transportation, and distribution, within a specific region. By strategically locating hydrogen production facilities, storage infrastructure, and refueling stations, hydrogen hubs and regional networks optimize the supply chain by reducing transportation distances and improving cost-efficiency.

- Digitalization and Data Analytics: The digitalization of the hydrogen supply chain through advanced data analytics, machine learning, and artificial intelligence will enable real-time monitoring, predictive maintenance, and optimization of operations. Smart sensors, IoT devices, and data analytics platforms will provide valuable insights into supply chain performance, asset management, energy optimization, and demand forecasting. This data-driven approach will enhance the efficiency and reliability of the hydrogen supply chain.

- Regulatory Support and International Collaboration: Government policies, regulations, and international collaborations will play a crucial role in driving hydrogen supply chain optimization. Supportive policies, such as financial incentives, carbon pricing mechanisms, and regulatory frameworks, will encourage investment in infrastructure, technology development, and research. International collaboration and standardization efforts will facilitate harmonization of safety regulations, infrastructure interoperability, and knowledge sharing, fostering the growth and optimization of the global hydrogen supply chain.

Collaborations and Further Research

Collaboration and further research are vital to advancing hydrogen supply chain optimization and accelerating the transition to a hydrogen-based economy. Role that MarketsandMarkets can play in supporting these efforts:

- Foster Collaboration: Stakeholders across the hydrogen value chain, including industry players, research institutions, policymakers, and investors, need to collaborate closely to drive innovation and optimize the hydrogen supply chain. By fostering collaboration, sharing best practices, and promoting knowledge exchange, we can collectively address challenges, identify opportunities, and accelerate the implementation of optimized supply chain solutions.

- Encourage Research and Development: Continued research and development are essential for identifying new technologies, materials, and processes that can enhance the efficiency, reliability, and sustainability of the hydrogen supply chain. Public and private research institutions should collaborate to explore innovative solutions, conduct feasibility studies, and validate new concepts. MarketsandMarkets can support these efforts by providing market intelligence, research reports, and insights on emerging trends and technologies in the hydrogen sector.

- Promote Standards and Regulations: Harmonized standards and regulations play a crucial role in ensuring the safe and efficient operation of the hydrogen supply chain. Collaboration among industry associations, governments, and regulatory bodies is essential to develop consistent safety standards, interoperable infrastructure guidelines, and regulatory frameworks that foster the growth of hydrogen supply chain optimization. MarketsandMarkets can contribute by providing market insights and analysis to inform policymakers and regulatory authorities in shaping effective policies and regulations.

- Facilitate Knowledge Sharing: Platforms for knowledge sharing, such as conferences, workshops, and industry forums, are instrumental in bringing together experts and stakeholders to share experiences, present research findings, and discuss challenges and opportunities in hydrogen supply chain optimization. MarketsandMarkets can organize and support industry events and conferences, providing a platform for networking, knowledge exchange, and collaboration among professionals in the hydrogen sector.

- Market Intelligence and Insights: MarketsandMarkets, as a leading market research and consulting firm, can contribute to hydrogen supply chain optimization by providing comprehensive market intelligence, insights, and forecasts. Through in-depth research reports, analysis, and consulting services, MarketsandMarkets can help stakeholders understand market trends, identify growth opportunities, assess technological advancements, and make informed decisions regarding supply chain optimization strategies and investments.

By fostering collaboration, encouraging research, promoting standards, facilitating knowledge sharing, and providing market intelligence, MarketsandMarkets can play a vital role in supporting the hydrogen industry's efforts towards supply chain optimization. Together, we can drive the transition to a sustainable hydrogen economy and unlock the full potential of hydrogen as a clean energy carrier.

Frequently Asked Questions (FAQ):

What is supply chain optimization for hydrogen?

Supply chain optimization for hydrogen involves improving the efficiency and reliability of the processes involved in producing, storing, transporting, and distributing hydrogen, aiming to minimize costs, reduce environmental impact, and ensure a steady supply of hydrogen for various applications. It includes optimizing production methods, infrastructure development, logistics planning, and demand forecasting.

What are the challenges of hydrogen value chain?

Challenges in the hydrogen value chain include high production costs, limited infrastructure for storage and distribution, and the need for advancements in hydrogen production technologies. Additionally, ensuring a sustainable and scalable hydrogen supply, addressing safety concerns, and establishing regulatory frameworks are also significant challenges to be addressed.

What is the hydrogen value chain model?

The hydrogen value chain model represents the sequential stages involved in the production, storage, transportation, and utilization of hydrogen. It encompasses hydrogen production, purification, storage, distribution, and end-use applications, with each stage interconnected to create a comprehensive system for the generation and utilization of hydrogen as an energy carrier.

What are the different types of hydrogen supply?

The different types of hydrogen supply include grey hydrogen, which is produced from fossil fuels with carbon emissions; blue hydrogen, which is produced from fossil fuels with carbon capture and storage; and green hydrogen, which is produced through electrolysis powered by renewable energy sources, such as wind or solar power.