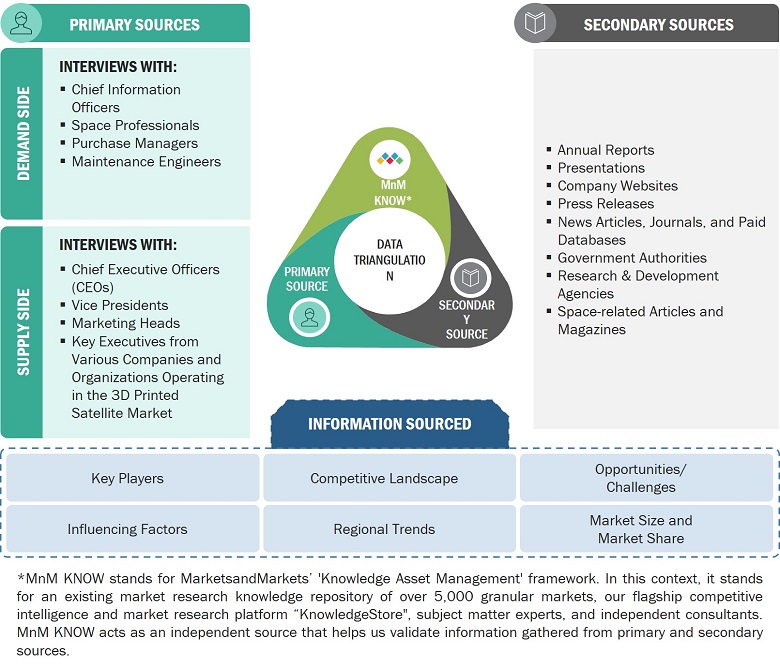

This research study on the 3D printed satellite market involved the extensive use of secondary sources, directories, and databases, such as D&B Hoovers, Bloomberg BusinessWeek, and Factiva, to identify and collect information relevant to the market. Primary sources considered included industry experts, as well as component manufacturers, system providers, technology developers, alliances, and organizations related to all segments of the value chain of the 3D printed satellite market. In-depth interviews with various primary respondents, including key industry participants, subject-matter experts, industry consultants, and C-level executives, were conducted to obtain and verify critical qualitative and quantitative information pertaining to the market, as well as assess its growth prospects.

Secondary Research

The ranking analysis of companies in the 3D printed satellite market was determined using secondary data from paid and unpaid sources and by analyzing major companies’ product portfolios and service offerings. These companies were rated based on the performance and quality of their 3d printed components. These data points were further validated by primary sources.

Secondary sources referred for this research study on the 3D printed satellite market included financial statements of companies offering 3D printed satellite components, along with various trade, business, and professional associations, among others. The secondary data was collected and analyzed to arrive at the overall size of the 3D-printed satellite market, which was validated by primary respondents.

In addition, the secondary research was used to obtain key information about the industry’s value chain and supply chain to identify key players operating in the market; market classifications and segmentation according to offerings of major players; and industry trends related to the components, application, manufacturing technique, satellite mass, and regions as well as key developments in the market.

Primary Research

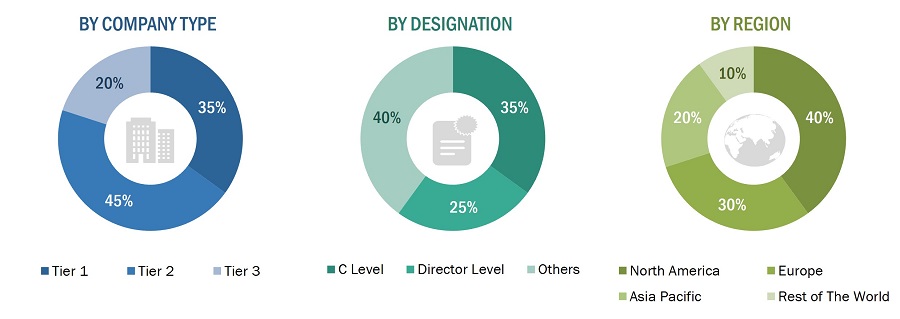

Extensive primary research was conducted after obtaining information about the current scenario of the 3D printed satellite market through secondary research. Several primary interviews were conducted with market experts from both the demand and supply sides across four regions: North America, Europe, Asia Pacific, the rest of the world. This primary data was collected through questionnaires, emails, and telephonic interviews.

These interviews were conducted to gather insights such as market statistics, data on revenue collected from the products and services, market breakdowns, market size estimations, market size forecasting, and data triangulation. It also helped analyze the components, application, manufacturing technique, satellite mass segments of the market for four key regions.

To know about the assumptions considered for the study, download the pdf brochure

Market Size Estimation

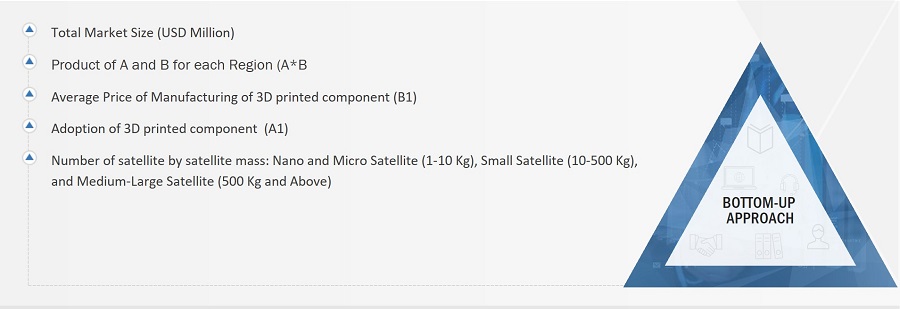

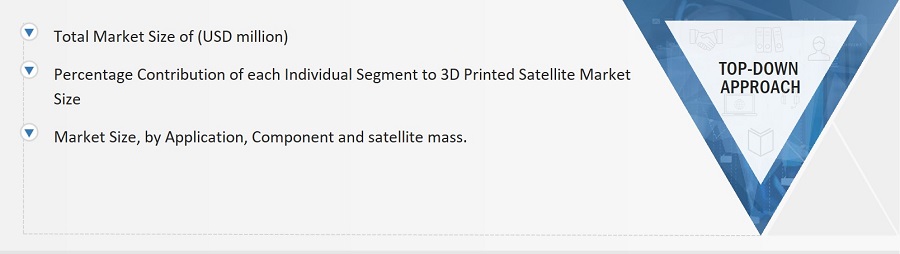

Both the top-down and bottom-up approaches have been used to estimate and validate the size of the market. The research methodology used to estimate the market size also includes the following details:

The key players were identified through secondary research, and their market ranking was determined through primary and secondary research. This included a study of the annual and financial reports of the top market players and extensive interviews of leaders, including chief executive officers (CEO), directors, and marketing executives.

All percentage shares, splits, and breakdowns were determined using secondary sources and verified through primary sources. All possible parameters that affect the markets covered in this research study were accounted for, viewed in extensive detail, verified through primary research, and analyzed to obtain the final quantitative and qualitative data. This data was consolidated, enhanced with detailed inputs, analyzed by MarketsandMarkets, and presented in this report.

Market size estimation methodology: Bottom-up Approach

Market size estimation methodology: Top- Down Approach

Data Triangulation

After arriving at the overall size of the 3D printed satellite market from the market size estimation process explained above, the total market was split into several segments and subsegments. To complete the overall market engineering process and arrive at the exact statistics for various market segments and subsegments, data triangulation and market breakdown procedures explained below were implemented, wherever applicable. The data was triangulated by studying various factors and trends from both the demand and supply sides. Along with this, the market size was validated using both top-down and bottom-up approaches.

Market Definition

3D printing, also known as additive manufacturing, is a process used to manufacture components in a layer-by-layer process using 3D design data stored in a digital file. The technology aids designers in developing superior-quality parts without facing restrictions, such as production feasibility, cost, or complexity. 3D Printed Satellites Market is a rapidly growing market dedicated to prolonging the operational life of orbiting satellites. 3D printing technology enables the production of intricate components without the necessity for conventional soldering and welding processes, thereby mitigating structural concerns associated with these traditional methods.

The 3D printed satellite market has the potential to make space exploration more accessible and affordable. By reducing the cost and complexity of satellite manufacturing, 3D printing could enable more countries and companies to participate in the space industry. Satellites that have less physical weight are also given higher preference in space missions as their weight directly affects the costs involved in the manufacturing of components used in satellites.

Stakeholders

-

3D printed satellite manufacturers

-

Component Manufacturers

-

Space Contractors

-

Government and Defence organizations related to the market

-

Research Organizations

-

Investors and Venture Capitalists

-

Ministries of Defense

-

R&D Companies

Report Objectives

-

To define, describe, and forecast the size of the 3D printed satellite market based on satellite mass, application, components, manufacturing technique, and region.

-

To forecast the size of the various segments of the 3D printed satellite market based on four regions: North America, Europe, Asia Pacific, and the Rest of the World, along with key countries in each of these regions.

-

To identify and analyze key drivers, restraints, opportunities, and challenges influencing the growth of the market

-

To identify industry trends, market trends, and technology trends prevailing in the market

-

To analyze micromarkets with respect to individual technological trends, prospects, and their contribution to the overall market

-

To provide a detailed competitive landscape of the market and analyze competitive growth strategies such as new product developments, contracts, partnerships, joint ventures, agreements, and collaborations adopted by key players in the market

-

To identify the detailed financial position, key products, unique selling points, and key developments of leading companies in the market

-

To strategically profile key market players and comprehensively analyze their market rank analysis and core competencies.

Available customizations

Along with the market data, MarketsandMarkets offers customizations as per the specific needs of companies. The following customization options are available for the report:

Product Analysis

-

Product matrix, which gives a detailed comparison of the product portfolio of each company

Regional Analysis

-

Further breakdown of the market segments at country-level

Company Information

-

Detailed analysis and profiling of additional market players (up to 5)

Growth opportunities and latent adjacency in 3D Printed Satellite Market