The research process for this technical, market-oriented, and commercial study of the painting robot market included the systematic gathering, recording, and analysis of data about customers and companies operating in the market. It involved the extensive use of secondary sources, directories, and databases (Factiva, Oanda, and OneSource) to identify and collect relevant information. In-depth interviews were conducted with various primary respondents, including experts from core and related industries and preferred manufacturers, to obtain and verify critical qualitative and quantitative information as well as to assess the growth prospects of the market. Key players in the painting robot market were identified through secondary research, and their market rankings were determined through primary and secondary research. This included studying annual reports of top players and interviewing key industry experts, such as CEOs, directors, and marketing executives.

Secondary Research

Various In the secondary research process, various secondary sources were used to identify and collect information for this study. These include annual reports, press releases, and investor presentations of companies, whitepapers, certified publications, and articles from recognized associations and government publishing sources. Research reports from a few consortiums and councils were also consulted to structure qualitative content. Secondary sources included corporate filings (such as annual reports, investor presentations, and financial statements); trade, business, and professional associations; white papers; Robotics journals and certified publications; articles by recognized authors; gold-standard and silver-standard websites; directories; and databases. Data was also collected from secondary sources, such as the International Federation of Robotics (IFR), the International Trade Centre (ITC) (Switzerland), and the Robotics Business Review (RBR).

Primary Research

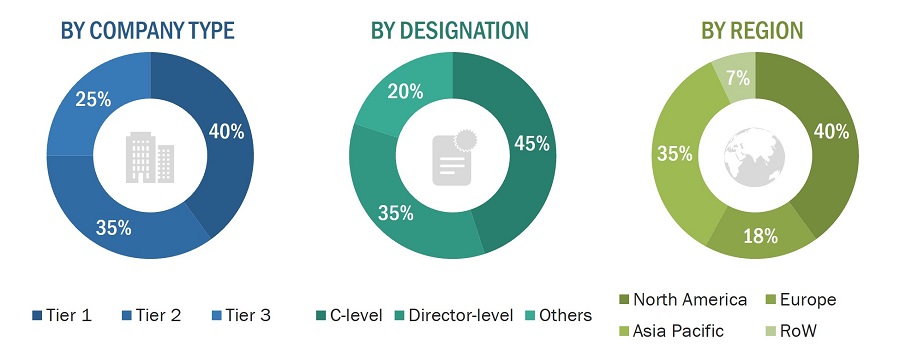

Extensive primary research was accomplished after understanding and analyzing the painting robot market scenario through secondary research. Several primary interviews were conducted with key opinion leaders from both demand- and supply-side vendors across four major regions—North America, Europe, Asia Pacific, and RoW. Approximately 30% of the primary interviews were conducted with the demand side, and 70% with the supply side. Primary data was collected through questionnaires, emails, and telephonic interviews. Various departments within organizations, such as sales, operations, and administration, were contacted to provide a holistic viewpoint in the report.

To know about the assumptions considered for the study, download the pdf brochure

Market Size Estimation

In the complete market engineering process, both top-down and bottom-up approaches were used, along with several data triangulation methods, to estimate and forecast the size of the market and its segments and subsegments listed in the report. Extensive qualitative and quantitative analyses were carried out on the complete market engineering process to list the key information/insights pertaining to painting robot market.

The key players in the market were identified through secondary research, and their rankings in the respective regions determined through primary and secondary research. This entire procedure involved the study of the annual and financial reports of top players, and interviews with industry experts such as chief executive officers, vice presidents, directors, and marketing executives for quantitative and qualitative key insights. All percentage shares, splits, and breakdowns were determined using secondary sources and verified through primary sources. All parameters that affect the markets covered in this research study were accounted for, viewed in extensive detail, verified through primary research, and analyzed to obtain the final quantitative and qualitative data. This data was consolidated, supplemented with detailed inputs and analysis from MarketsandMarkets, and presented in this report.

Painting Robot Market: Bottom-Up Approach

The bottom-up procedure was employed to arrive at the overall size of the Painting robot market from revenues of the key players and their share in the market. The overall market size was calculated on the basis of the revenues of the key companies identified in the market.

Painting Robot Market: Top-Down Approach

In the top-down approach, the overall size of the Painting robot market was used to estimate the size of the individual markets (mentioned in the market segmentation) through percentage splits obtained from secondary and primary research. To calculate the size of the specific market segments, the size of the most appropriate parent market was used to implement the top-down approach. The bottom-up approach was also implemented for the data extracted from the secondary research to validate the size of various segments of the Painting robot market. The share of each company in the market was estimated to verify the revenue shares used earlier in the bottom-up approach. With the data triangulation procedure and the validation of data through primaries, sizes of the parent market and each individual market were determined and confirmed. The data triangulation procedure used for this study has been explained in the next section.

Data Triangulation

After arriving at the overall market size from the market size estimation process explained above, the total market was split into several segments and subsegments. Data triangulation and market breakdown procedures were employed, wherever applicable, to complete the overall market engineering process and arrive at the exact statistics for all segments and subsegments. The data was triangulated by studying various factors and trends from both demand and supply sides. Along with this, the market size was validated using both top-down and bottom-up approaches.

Market Definition

A painting robot is an automated system designed to apply paint to surfaces independently, without human intervention. It utilizes specialized mechanisms and sophisticated software to achieve precise and uniform paint application on objects of diverse shapes and sizes. Known for their high accuracy and stability, these robots can meticulously control the thickness of the paint layer, delivering superior quality coatings.

The study covers painting robots equipped with robot arms, end effectors, software, and other hardware components, designed to apply paint or coatings on surfaces with precision. The robots are often used in the automotive & transportation, consumer appliances, furniture, construction, heavy engineering equipment, and other industries.

Key Stakeholders

-

Painting robot manufacturers

-

Painting robot component providers

-

Technology investors

-

Governments and financial institutions

-

Analysts and strategic business planners

-

Existing and prospective end users

-

Painting robot software providers

-

Painting robot-related associations, organizations, forums, and alliances

-

Venture capitalists, private equity firms, and startup companies

-

Distributors and traders

-

Research institutes and organizations

Report Objectives

-

To define, describe, segment, and forecast the painting robot market size, in terms of value, based on mounting type, robot type, payload, reach, function, paint applicator, and end-use industry

-

To define, describe, segment, and forecast the painting robot market size, in terms of volume, for painting robot arms

-

To forecast the market size, in terms of value, across North America, Europe, Asia Pacific, and the Rest of the World (RoW)

-

To present detailed information regarding the major factors influencing the growth of the market (drivers, restraints, opportunities, and challenges)

-

To provide an ecosystem analysis, case study analysis, patent analysis, technology analysis, ASP analysis, Porter’s Five Forces analysis, and regulations pertaining to the market.

-

To offer a comprehensive overview of the value chain of the painting robot market ecosystem

-

To critically analyze micromarkets1 with respect to individual growth trends, prospects, and contributions to the total market

-

To strategically profile the key players and comprehensively analyze their market shares and core competencies

-

To assess the opportunities in the market for stakeholders and describe the competitive landscape of the market

-

To analyze competitive developments in the market, such as collaborations, agreements, partnerships, product developments, and research and development (R&D)

-

To evaluate the impact of the recession on the painting robot market

Available Customizations:

With the given market data, MarketsandMarkets offers customizations according to the company’s specific needs. The following customization options are available for the report:

Company Information

-

Detailed analysis and profiling of additional market players (up to 7)

Growth opportunities and latent adjacency in Painting Robot Market