The study involved four major activities for estimating the current size of the global flexible eco-friendly plasticizers market. Exhaustive secondary research was conducted to collect information on the market, the peer product market, and the parent product group market. The next step was to validate these findings, assumptions, and sizes with the industry experts across the value chain of eco-friendly plasticizers through primary research. Both the top-down and bottom-up approaches were employed to estimate the overall size of the eco-friendly plasticizers market. After that, market breakdown and data triangulation procedures were used to determine the size of different segments and sub-segments of the market.

Secondary Research

In the secondary research process, various secondary sources such as Hoovers, Factiva, Bloomberg BusinessWeek, and Dun & Bradstreet were referred, to identify and collect information for this study on the eco-friendly plasticizers market. These secondary sources included annual reports, press releases & investor presentations of companies; white papers; certified publications; articles by recognized authors; regulatory bodies, trade directories, and databases.

Primary Research

The eco-friendly plasticizers market comprises several stakeholders in the supply chain, which include raw material suppliers, processors, end-product manufacturers, buyers, and regulatory organizations. Various primary sources from the supply and demand sides of the markets have been interviewed to obtain qualitative and quantitative information. The primary participants from the demand side include key opinion leaders, executives, vice presidents, and CEOs of companies in the eco-friendly plasticizers market. Primary sources from the supply side include associations and institutions involved in the eco-friendly plasticizers market, key opinion leaders, and processing players.

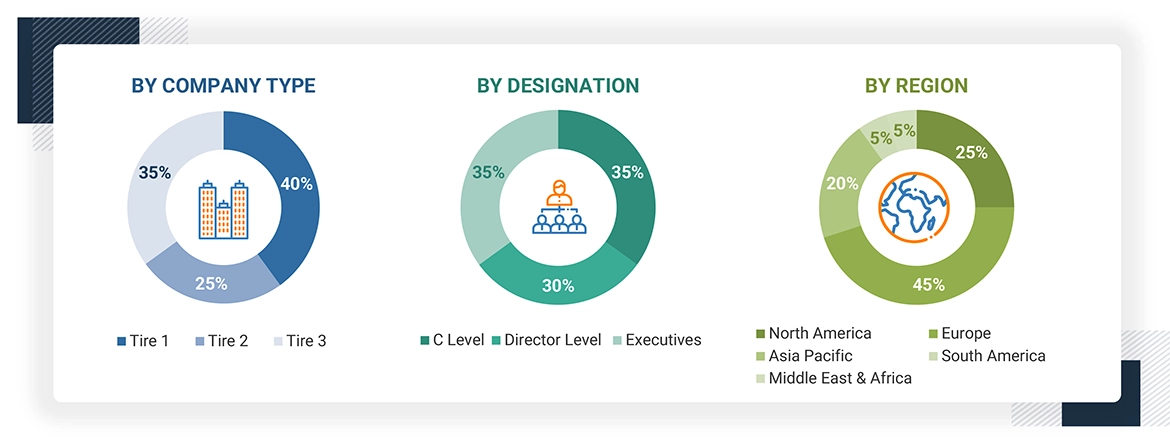

Following is the breakdown of primary respondents:

To know about the assumptions considered for the study, download the pdf brochure

Market Size Estimation

The bottom-up and top-down approaches have been used to estimate the eco-friendly plasticizers market by packaging product, application, and region. The research methodology used to calculate the market size includes the following steps:

-

The key players in the industry and markets were identified through extensive secondary research.

-

In terms of value, the industry’s supply chain and market size were determined through primary and secondary research processes.

-

All percentage shares, splits, and breakdowns were determined using secondary sources and verified through primary sources.

-

All possible parameters that affect the markets covered in this research study were accounted for, viewed in extensive detail, verified through primary research, and analyzed to obtain the final quantitative and qualitative data.

-

The research included studying reports, reviews, and newsletters of top market players and extensive interviews with leaders such as directors and marketing executives to obtain opinions.

The following figure illustrates the overall market size estimation process employed for this study.

Data Triangulation

After arriving at the overall size of the eco-friendly plasticizer market from the estimation process explained above, the total market was split into several segments and sub-segments. The data triangulation and market breakdown procedures were employed, wherever applicable, to complete the overall market engineering process and arrive at the exact statistics for all segments and subsegments. The data was triangulated by studying various factors and trends from both the demand and supply sides. Along with this, the market size was validated using both the top-down and bottom-up approaches.

Market Definition

The definition of eco-friendly plasticizers is additives that enhance the flexibility and workability of plastic materials, bringing a very minimal effect on the environment and health. The basis of these plasticizers is renewable sources or such that they are known to be nontoxic, providing safer alternatives in contrast to traditional phthalate-based plasticizers that have been linked to various health risks, including endocrine disruption. There is building momentum within the eco-friendly plasticizer space from growing consumer awareness around sustainability, stringent regulatory requirements, and upticks in demand for greener products across multiple industries including packaging, automotive, and construction. As the carbon footprint of industries continues to minimize and conform to standards based on environmental regulations, the presence of ecological plasticizers is turning into a vital component of creating sustainable materials that will significantly promote innovation and growth in this market.

Stakeholders

-

Eco-Friendly Plasticizer Manufacturers

-

Raw Material Suppliers

-

Regulatory Bodies and Government Agencies

-

Distributors and Suppliers

-

End-Use Industries

-

Associations and Industrial Bodies

-

Market Research and Consulting Firms

Report Objectives

-

To define, describe, and forecast the size of the eco-friendly plasticizers market in terms of value and volume.

-

To provide detailed information regarding the key factors influencing the growth of the market (drivers, restraints, opportunities, and challenges).

-

To forecast the market size based on product, application and region.

-

To forecast the market size for the five main regions—North America, Europe, Asia Pacific (APAC), South America and the Middle East & Africa (MEA),—along with their key countries.

-

To strategically analyze micro markets with respect to individual growth trends, prospects, and contributions to the total market.

-

To analyze the opportunities in the market for stakeholders and provide details of the competitive landscape for the market leaders.

-

To strategically profile leading players and comprehensively analyze their key developments such as new product launches, expansions, and deals in the eco-friendly plasticizers market.

-

To strategically profile key players and comprehensively analyze their market shares and core competencies.

-

To study the impact of AI/Gen AI on the market under study, along with the macroeconomic outlook.

Growth opportunities and latent adjacency in Eco-Friendly Plasticizers Market