The study involved four major activities for estimating the current size of the global arc welding torch market. Exhaustive secondary research was carried out to collect information on the market, the peer product market, and the parent product group market. The next step was to validate these findings, assumptions, and sizes with the industry experts across the value chain of arc welding torch through primary research. Both the top-down and bottom-up approaches were employed to estimate the overall size of the arc welding torch market. After that, market breakdown and data triangulation procedures were used to determine the size of different segments and sub-segments of the market.

Secondary Research

In the secondary research process, various secondary sources such as Hoovers, Factiva, Bloomberg BusinessWeek, and Dun & Bradstreet were referred to, to identify and collect information for this study on the arc welding torch market. These secondary sources included annual reports, press releases & investor presentations of companies; white papers; certified publications; articles by recognized authors; regulatory bodies, trade directories, and databases.

Primary Research

The arc welding torch market comprises several stakeholders in the supply chain, which include raw material suppliers, processors, end-product manufacturers, buyers, and regulatory organizations. Various primary sources from the supply and demand sides of the markets have been interviewed to obtain qualitative and quantitative information. The primary participants from the demand side include key opinion leaders, executives, vice presidents, and CEOs of companies in the arc welding torch market. Primary sources from the supply side include associations and institutions involved in the arc welding torch industry, key opinion leaders, and processing players.

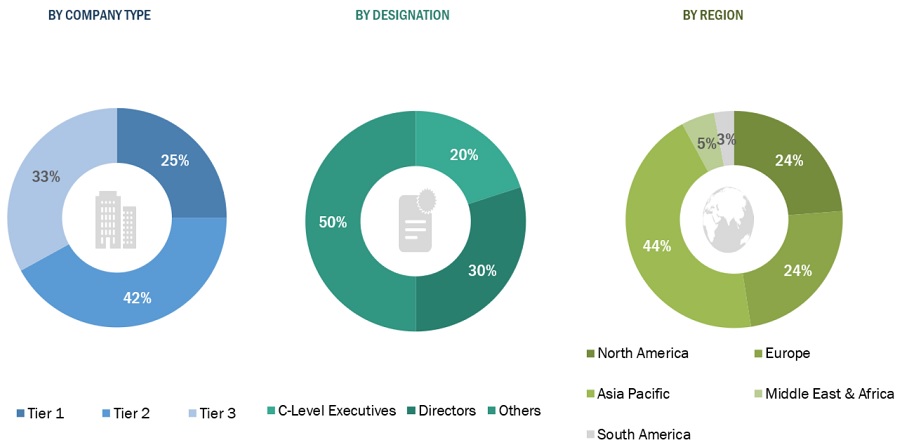

Following is the breakdown of primary respondents

Notes: Other designations include product, sales, and marketing managers.

Tiers of the companies are classified based on their annual revenues as of 2022: Tier 1 = >USD 5 Billion, Tier 2 = USD 1 Billion to USD 5 Billion, and Tier 3= <USD 1 Billion.

To know about the assumptions considered for the study, download the pdf brochure

Market Size Estimation

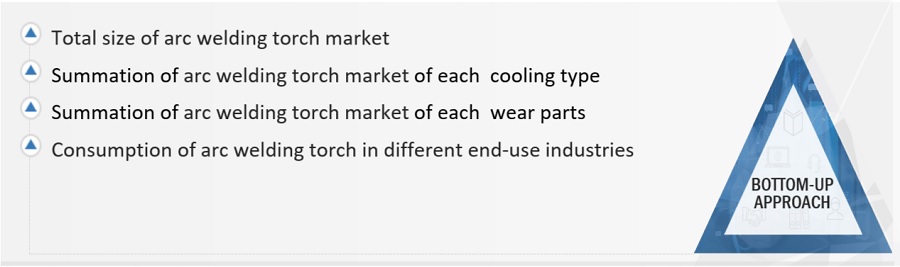

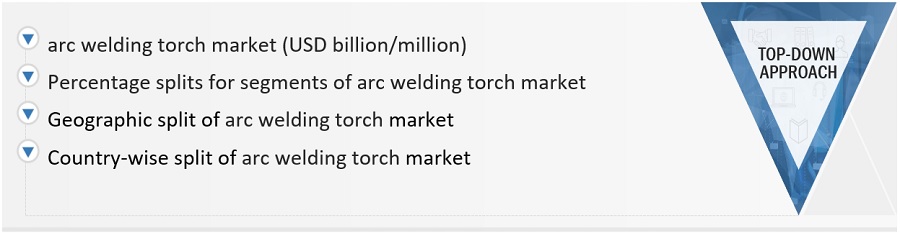

Both the top-down and bottom-up approaches were used to estimate and validate the size of the global arc welding torch market. These approaches were also used extensively to estimate the size of various segments of the market. The research methodology used to estimate the market size included the following details:

-

The key players in the industry were identified through extensive secondary research.

-

The supply chain of the industry and market size, in terms of value, were determined through primary and secondary research.

-

All percentage share splits and breakdowns were determined using secondary sources and verified through primary sources.

-

All possible parameters that affect the markets covered in this research study were accounted for, viewed in extensive detail, verified through primary research, and analyzed to obtain the final quantitative and qualitative data.

-

The research includes the study of reports, reviews, and newsletters of key industry players, along with extensive interviews with key officials, such as directors and marketing executives.

To know about the assumptions considered for the study, Request for Free Sample Report

Data Triangulation

After arriving at the overall market size from the estimation process explained above, the total market was split into several segments and sub-segments. The data triangulation and market breakdown procedures were employed, wherever applicable, to complete the overall market engineering process and arrive at the exact statistics for all the segments and sub-segments of the arc welding torch market. The data was triangulated by studying various factors and trends from both the demand- and supply-side.

In addition, the market size was validated by using both the top-down and bottom-up approaches. Then, it was verified through primary interviews. Hence, for every data segment, there are three sources—top-down approach, bottom-up approach, and expert interviews. The data were assumed to be correct when the values arrived at from the three sources matched.

Market Definition

Arc welding is a widely used method for fusing metals together in the category of fusion welding. This technique utilizes an electric arc to generate high heat that melts and fuses metals together. A power source is used to create an electric arc between a consumable or non-consumable electrode and the base metal. Arc welders can operate with both direct current (DC) and alternating current (AC), providing flexibility for various welding applications.

The arc welding torch market encompasses the global landscape of devices essential for welding operations across various end-use industries. The arc welding torch, also known as the welding gun or welding torch assembly, is a crucial component of the arc welding process. It consists of several parts, including the handle, trigger, nozzle, and electrode holder. The torch is connected to the power source and guides the electrode to the desired welding location. The electrode, which can be made of various materials such as steel, aluminum, or flux-coated wire, is fed through the torch and is consumed during the welding process. The torch also directs the shielding gas, if needed, to protect the weld area from atmospheric contamination.

Market segmentation within this industry is based on several factors, including cooling types, end-use industries, and wear parts. Different cooling mechanisms, such as air-cooled and water-cooled torches, cater to diverse welding requirements and preferences. Additionally, segmentation by end-use industries reflects the varied applications of arc welding across sectors like automotive, construction, aerospace, and manufacturing. Furthermore, segmentation by wear parts accounts for the replacement and maintenance needs of torch components, ensuring optimal performance and longevity. As welding continues to be an indispensable process across numerous sectors, the arc welding torch market remains dynamic, driven by technological advancements and evolving industrial demands.

Key Stakeholders

-

Arc welding torch manufacturers

-

Arc welding torch traders, distributors, and suppliers

-

End-use industry participants of different segments

-

Government and research organizations

-

Associations and industrial bodies

-

Research and consulting firms

-

R&D institutions

-

Environment support agencies

-

Investment banks and private equity firms

Report Objectives

-

To define, analyze, and project the size of the arc welding torch market in terms of value based on wear parts, cooling type, end-use industries and region.

-

To project the size of the market and its segments with respect to the five main regions, namely, North America, Europe, Asia Pacific, Middle East & Africa, and South America

-

To provide detailed information about the key factors, such as drivers, restraints, opportunities, and challenges, influencing the growth of the market

-

To analyze the opportunities in the market for stakeholders and provide a detailed competitive landscape of the market leaders.

-

To analyze the competitive developments, such as new product launches, expansions, and acquisitions, in the arc welding torch market

-

To strategically profile the key players operating in the market and comprehensively analyze their market shares and core competencies.

Available Customizations

Along with the given market data, MarketsandMarkets offers customizations as per the specific needs of the companies. The following customization options are available for the report:

Product Analysis:

-

Product Matrix which gives a detailed comparison of the product portfolio of each company

Regional Analysis:

-

Further breakdown of the Rest of Asia Pacific market

-

Further breakdown of Rest of Europe market

Company Information:

-

Detailed analysis and profiling of additional market players (up to 5)

Growth opportunities and latent adjacency in Arc Welding Torch Market