Future of Collaborative Robots: Key Trends and Emerging Technologies

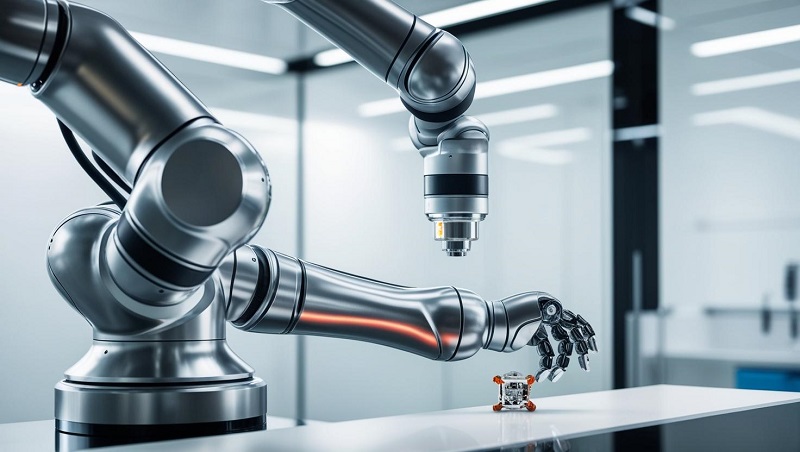

The rise of collaborative robots or cobots is one of the most exciting developments in the world of automation. As businesses across industries increasingly embrace Industry 4.0 technologies, cobots are transforming how humans and machines work together. Unlike traditional industrial robots, which are typically confined to working in isolation, cobots are designed to work alongside humans, enhancing productivity, safety, and efficiency in a range of applications.

Recent collaborative robot (cobot) market projections indicate a surge in adoption, with analysts forecasting a compound annual growth rate (CAGR) of over 35.2%in the coming years.

As technology advances and industries evolve, the future of collaborative robots looks promising. Explores the potential of cobots, the trends driving their growth, and the challenges and opportunities ahead.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=194541294

Key Trends Shaping the Future of Collaborative Robots

1. Increased Adoption Across Industries

The demand for cobots is growing rapidly across various sectors, including manufacturing, logistics, healthcare, agriculture, and retail. Their versatility, ease of programming, and ability to improve worker safety are key factors driving adoption.

- Manufacturing: Cobots are revolutionizing production lines by assisting with tasks like assembly, welding, quality control, and material handling. They are particularly useful in small and medium-sized enterprises (SMEs) that may not have the resources to invest in traditional automation systems. Cobots enhance operational efficiency and allow employees to focus on more complex or value-added tasks.

- Logistics and Warehousing: In e-commerce and logistics, cobots are used for order picking, sorting, and packaging. They help improve operational efficiency, reduce human error, and enhance throughput, especially during peak seasons.

- Healthcare: Cobots are being used in surgeries, rehabilitation, and laboratory tasks. They provide assistance to medical professionals, improve precision, and reduce fatigue, contributing to better outcomes in patient care.

- Agriculture: Cobots are also making waves in agriculture, where they assist with planting, harvesting, and monitoring crops. This helps improve productivity while minimizing the physical demands placed on human workers.

2. Advances in AI and Machine Learning

As cobots evolve, they are becoming increasingly sophisticated, thanks to advancements in artificial intelligence (AI) and machine learning. These technologies enable cobots to learn from their environment, adapt to changes, and make decisions in real-time.

AI-powered cobots can optimize their movements and actions based on real-time data, improving efficiency and accuracy. Machine learning algorithms allow them to handle more complex tasks, such as inspecting products for defects, identifying objects, and adjusting to variations in the work environment. As AI continues to improve, cobots will become even more capable of performing a wider range of tasks, making them even more valuable across industries.

3. Human-Robot Collaboration

One of the most significant trends in the future of cobots is the increasing emphasis on human-robot collaboration. As automation technology advances, there is growing recognition that humans and robots can complement each other, leveraging their unique strengths.

Humans excel at tasks requiring creativity, dexterity, and decision-making, while robots are better suited for repetitive, dangerous, or physically demanding tasks. Cobots enable workers to offload mundane or physically taxing work, allowing them to focus on more strategic, creative, and value-added activities. This synergy leads to higher job satisfaction, fewer injuries, and improved productivity.

4. Ease of Use and Programming

Historically, robots have been complex and costly to program, often requiring specialized knowledge and training. However, one of the defining features of cobots is their user-friendly design, which allows workers without technical expertise to program and operate them easily.

Cobots often come with intuitive graphical interfaces, drag-and-drop programming, and pre-configured applications that make them accessible to a wider range of workers. This ease of use allows businesses to deploy cobots more quickly, reducing the time required for training and integration into production processes.

5. Cost Efficiency and Scalability

Unlike traditional industrial robots, which often require significant upfront investments and dedicated space, cobots are more affordable and scalable. They can be deployed in a variety of applications and easily integrated into existing workflows.

Cobots are ideal for small and medium-sized businesses (SMBs) looking to automate without breaking the bank. Their low cost and flexibility allow businesses to start small and scale their automation efforts as needed, gradually increasing their use as the business grows.

Emerging Technologies Shaping the Future of Collaborative Robots

The world is undergoing a technological revolution, with collaborative robots (cobots) industry emerging as a key component in transforming industries. Unlike traditional industrial robots, which work in isolation from humans, cobots are designed to work alongside people, enhancing productivity, safety, and flexibility. As they evolve, cobots are becoming integral in diverse sectors, ranging from manufacturing and logistics to healthcare and agriculture. Their ability to collaborate with humans while performing tasks that require precision, adaptability, and safety is reshaping the future of work.

Advancements in Artificial Intelligence and Machine Learning

AI and machine learning have significantly advanced the capabilities of cobots. These technologies allow cobots to learn from their environment, improve over time, and make real-time decisions. AI enables cobots to handle complex tasks like identifying defective parts during assembly or adjusting to changes in the work environment. Machine learning allows them to recognize patterns and improve decision-making based on real-time data. As AI continues to progress, cobots will be able to handle more sophisticated tasks, pushing the boundaries of what is possible in automation.

Human-Robot Collaboration

One of the most significant features of collaborative robots is their ability to work seamlessly with human workers. Cobots are designed to assist in repetitive, physically demanding, or hazardous tasks, freeing up humans to focus on more complex and creative responsibilities. This collaboration boosts productivity, improves safety by reducing strain on workers, and fosters a more efficient work environment. Cobots are becoming indispensable in industries where tasks require a balance of human ingenuity and machine precision, enabling workers to enhance their skills and work more effectively with machines.

Advanced Sensors and Safety Features

Cobots are equipped with advanced sensors and safety mechanisms, allowing them to interact safely and intelligently with their human colleagues. Force and torque sensors, vision systems, and proximity sensors enable cobots to detect human presence, adjust their movements, and avoid collisions. These safety features make cobots suitable for use in dynamic, unstructured environments without the need for safety barriers or cages, unlike traditional industrial robots. This ability to work safely alongside people is one of the main reasons for the growing adoption of cobots in industries such as manufacturing, healthcare, and logistics.

Collaborative Robotics in Industry 4.0

As part of the Industry 4.0 revolution, cobots are playing a central role in the transformation of manufacturing and production. Industry 4.0 emphasizes automation, connectivity, and real-time data analysis, creating a perfect environment for the deployment of cobots. Cobots are seamlessly integrated into smart factories, communicating with other machines and IoT devices to optimize production processes. They enable increased flexibility and customization on production lines, allowing businesses to quickly adapt to new products and changing consumer demands. The data generated by cobots also contributes to real-time monitoring and decision-making, making operations more efficient.

Expansion into New Industries

While cobots are already prevalent in manufacturing and logistics, their impact is expanding into new industries. In healthcare, cobots are assisting with surgeries, offering precision and reducing the risk of human error. In agriculture, cobots are used for planting, harvesting, and monitoring crops, improving productivity while minimizing labor costs. Cobots are also entering the retail sector, where they assist with inventory management and product handling in warehouses and stores. The versatility and flexibility of cobots are allowing them to be deployed across diverse industries, each benefiting from their ability to increase efficiency and safety.

User-Friendly Programming and Integration

One of the major barriers to the widespread adoption of industrial robots has traditionally been the complexity of programming and integration. However, cobots are designed to be user-friendly, requiring minimal technical expertise to program and operate. With intuitive interfaces, easy-to-follow programming methods, and plug-and-play capabilities, cobots are accessible to a broader range of industries, including small and medium-sized businesses. The ability to quickly deploy cobots and integrate them into existing workflows without significant changes or costly infrastructure upgrades is one of the key factors driving their popularity.

Cost-Effective Automation

Another significant advantage of collaborative robots is their cost-effectiveness compared to traditional industrial robots. Cobots are typically less expensive, making them an attractive option for companies seeking automation solutions without the large upfront costs associated with traditional robots. In addition to the lower initial investment, cobots have low operational costs, require less maintenance, and are energy-efficient. Their flexibility also allows businesses to scale their automation efforts incrementally, enabling them to invest in cobots as their operations grow and evolve.

The future of collaborative robots is incredibly bright, with continued advancements in artificial intelligence, machine learning, and sensor technologies driving their evolution. Cobots are poised to become a key part of the future of work, transforming industries and creating new possibilities for human-robot collaboration. As they become more sophisticated, adaptable, and accessible, cobots will play a central role in improving efficiency, productivity, and safety across industries. The ongoing integration of cobots into diverse sectors, combined with their cost-effectiveness and ease of use, will make them a vital tool in the automation landscape of the future.

FAQs

How do cobots differ from traditional industrial robots?

Cobots differ from traditional industrial robots in their ability to work directly with human workers without the need for physical barriers. While traditional robots are often used in isolated environments due to safety concerns, cobots are designed with built-in sensors and safety mechanisms that allow them to collaborate in dynamic, human-centric environments. Cobots are also generally more flexible and can be reprogrammed or redeployed for different tasks with ease.

What are the growth projections for the collaborative robots market?

The global Collaborative Robot market size was valued at USD 1.9 billion in 2024 and is estimated to reach USD 11.8 billion by 2030, Growing at a CAGR of 35.2% during the forecast period from 2024 to 2030

What are the main advantages of using cobots?

The main advantages of cobots include increased productivity, enhanced safety, and cost-effectiveness. Cobots can take over repetitive or dangerous tasks, allowing human workers to focus on higher-level activities. Their ability to work in a shared environment with humans improves efficiency and reduces the likelihood of injuries. Additionally, cobots are more affordable and require less upfront investment compared to traditional industrial robots.

How are cobots powered by AI and machine learning?

AI and machine learning play a critical role in enhancing the capabilities of cobots. These technologies allow cobots to adapt to new situations, improve their performance over time, and make intelligent decisions based on real-time data. For example, AI enables cobots to identify patterns, detect defects in products, and optimize their actions based on feedback, enhancing their overall efficiency.

What future advancements can we expect for cobots?

As AI, machine learning, and sensor technologies continue to improve, cobots will become even more sophisticated, capable of performing more complex tasks with greater precision. Future advancements may also include enhanced human-robot interaction capabilities, where cobots can learn and adapt more seamlessly to changing environments and tasks. Cobots may also be further integrated into sectors such as healthcare, logistics, and retail, offering even more specialized assistance and automation.

80% of the Forbes Global 2000 B2B companies rely on MarketsandMarkets to identify growth opportunities in emerging technologies and use cases that will have a positive revenue impact.

- Food Packaging Market Size Set for Strong Growth Through 2030 Amid Rising Demand for Convenience Foods

- Fertilizers Industry Set to Grow at 4.1% CAGR Through 2030

- Leading Automated Guided Vehicle Companies 2024: An In-depth Analysis

- CHARGED UP: SHIFT TO E-MOBILITY AND THE EVOLUTION OF TRANSPORTATION

- Global Automotive Market: Predictions For 2024