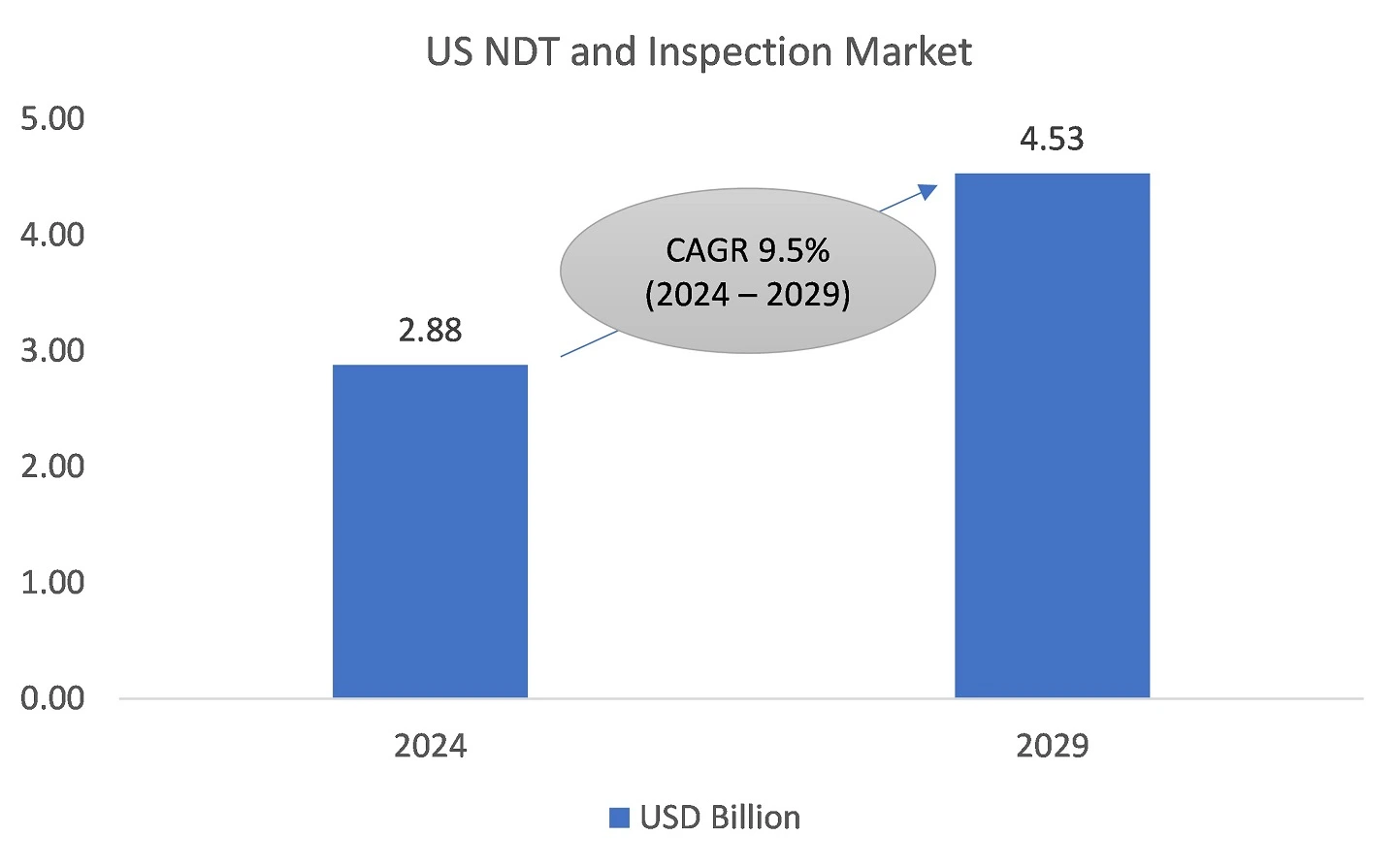

US NDT and Inspection Market

According to MarketsandMarkets, the US NDT and Inspection market is projected to grow from USD 2.88 billion in 2024 to reach USD 4.53 billion by 2029; it is expected to grow at a CAGR of 9.5% from 2024 to 2029.

Overview of the US NDT and Inspection Market

The Non-Destructive Testing (NDT) and inspection market in the United States is a critical component of the nation's industrial ecosystem, ensuring product safety, reliability, and compliance across sectors such as aerospace, automotive, oil and gas, power generation, and infrastructure. With a focus on innovation and precision, the US has established itself as a global leader in NDT, leveraging advanced technologies like ultrasonic testing, radiographic testing, and phased array systems. The market has seen significant growth, driven by the need for regular inspection of aging infrastructure, stringent safety regulations, and the increasing complexity of industrial operations. Automation and digitalization are further reshaping the industry, enhancing efficiency and accuracy.

Factors Driving Demand for NDT and Inspection Services in the US

Factors Driving Demand for NDT and Inspection Services in the US

The US NDT and inspection market is influenced by several key drivers. The country’s expansive infrastructure network, including bridges, pipelines, and power plants, necessitates frequent and thorough inspections to prevent failures and ensure public safety. The growing demand for renewable energy, including wind and solar power, also contributes to the need for advanced inspection solutions for turbines and other components. In aerospace, the US remains a leader in manufacturing and maintenance, requiring rigorous testing to meet strict safety standards. The automotive industry, particularly with the rise of electric vehicles (EVs), further boosts demand for NDT technologies to inspect batteries and components. Additionally, the emphasis on quality control and risk mitigation in critical industries drives the adoption of advanced inspection systems.

Laws and Regulations Supporting NDT and Inspection Services in the US

The US has a robust regulatory framework that supports the widespread adoption of NDT and inspection services. Agencies such as the Occupational Safety and Health Administration (OSHA), the Federal Aviation Administration (FAA), and the Department of Transportation (DOT) mandate strict compliance with safety and inspection standards. For example, pipeline inspections are governed by the Pipeline and Hazardous Materials Safety Administration (PHMSA), while the Nuclear Regulatory Commission (NRC) oversees inspections in the nuclear energy sector. Additionally, adherence to international standards like ASME (American Society of Mechanical Engineers) codes and ASTM (American Society for Testing and Materials) standards ensures the credibility of NDT processes. These regulations not only safeguard public welfare but also encourage the adoption of cutting-edge inspection technologies.

Impact of Generative AI on the NDT and Inspection Market in the US

Generative AI is revolutionizing the US NDT and inspection market by introducing advanced capabilities in defect detection, data analysis, and predictive maintenance. AI-powered systems can process vast amounts of inspection data in real-time, offering insights that surpass human capabilities. Predictive maintenance, enabled by AI algorithms, allows industries to identify potential issues before they escalate, reducing downtime and repair costs. Generative AI also facilitates the creation of realistic simulations, helping engineers optimize inspection processes and improve decision-making. The aerospace, automotive, and energy sectors are particularly benefiting from these advancements. However, the adoption of AI-driven solutions requires addressing challenges such as integration costs and workforce training.

Challenges in the US NDT and Inspection Market

Despite its growth, the US NDT and inspection market faces several challenges. One significant issue is the aging infrastructure, which increases the complexity and frequency of inspections, straining resources. Another challenge is the shortage of skilled NDT technicians, particularly as the industry increasingly adopts sophisticated technologies that require specialized expertise. The high costs associated with advanced inspection equipment and AI implementation can be prohibitive for small and medium-sized enterprises (SMEs). Additionally, global supply chain disruptions have impacted the availability of critical components and technologies, further complicating operations. To overcome these challenges, the industry must prioritize workforce development, invest in training programs, and promote collaborative innovation to make cutting-edge technologies more accessible.

Related Report

NDT and Inspection Market by Technique (Ultrasonic Testing, Visual, Magnetic Particle, Liquid Penetration, Eddy-Current, Radiographic, Acoustic Emission), Service, Method, Vertical, Application and Region - Global Forecast to 2029

Contact:

Mr. Rohan Salgarkar

MarketsandMarkets™ INC.

1615 South Congress Ave.

Suite 103

Delray Beach, FL 33445

USA : 1-888-600-6441

sales@marketsandmarkets.com

X

GET A FREE SAMPLE

This FREE sample includes market data points, ranging from trend analyses to market estimates & forecasts. See for yourself.

SEND ME A FREE SAMPLE