TABLE OF CONTENTS

1 INTRODUCTION (Page No. - 22)

1.1 STUDY OBJECTIVES

1.2 MARKET DEFINITION

1.2.1 INCLUSIONS & EXCLUSIONS

1.3 MARKET SCOPE

1.4 REGIONS COVERED

1.4.1 YEARS CONSIDERED

1.5 CURRENCY CONSIDERED

1.6 UNITS CONSIDERED

1.7 STAKEHOLDERS

1.8 SUMMARY OF CHANGES

2 RESEARCH METHODOLOGY (Page No. - 26)

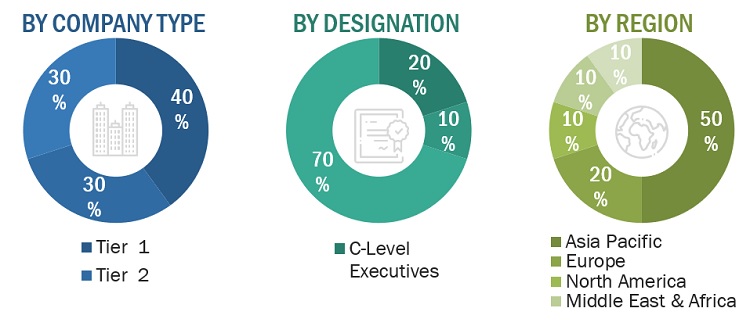

2.1 RESEARCH DATA

FIGURE 1 PTFE FABRIC MARKET: RESEARCH DESIGN

2.1.1 SECONDARY DATA

2.1.1.1 Key data from secondary sources

2.1.2 PRIMARY DATA

2.1.2.1 Key data from primary sources

2.1.2.2 Primary interviews – demand and supply sides

2.1.2.3 Key industry insights

2.1.2.4 Breakdown of primary interviews

2.2 MARKET SIZE ESTIMATION

2.2.1 BOTTOM-UP APPROACH

FIGURE 2 PTFE FABRIC MARKET: BOTTOM-UP APPROACH

2.2.2 TOP-DOWN APPROACH

FIGURE 3 PTFE FABRIC MARKET: TOP-DOWN APPROACH

FIGURE 4 MARKET SIZE ESTIMATION: PTFE FABRIC MARKET

2.3 FORECAST NUMBER CALCULATION

FIGURE 5 DEMAND-SIDE FORECAST PROJECTION

2.4 DATA TRIANGULATION

FIGURE 6 PTFE FABRIC MARKET: DATA TRIANGULATION

2.5 FACTOR ANALYSIS

2.6 ASSUMPTIONS

2.7 LIMITATIONS AND RISKS

3 EXECUTIVE SUMMARY (Page No. - 35)

FIGURE 7 PTFE COATED FABRIC SEGMENT TO LEAD MARKET DURING FORECAST PERIOD

FIGURE 8 FOOD SEGMENT TO DOMINATE MARKET BETWEEN 2022 AND 2027

FIGURE 9 ASIA PACIFIC ACCOUNTED FOR LARGEST SHARE IN 2021

4 PREMIUM INSIGHTS (Page No. - 38)

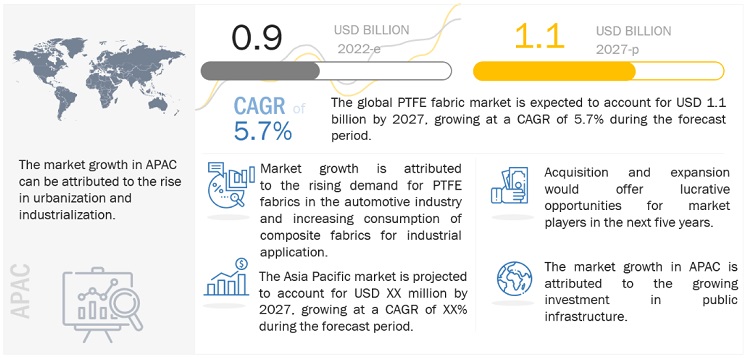

4.1 SIGNIFICANT OPPORTUNITIES IN PTFE FABRIC MARKET

FIGURE 10 HIGH GROWTH POTENTIAL IN ASIA PACIFIC DURING FORECAST PERIOD

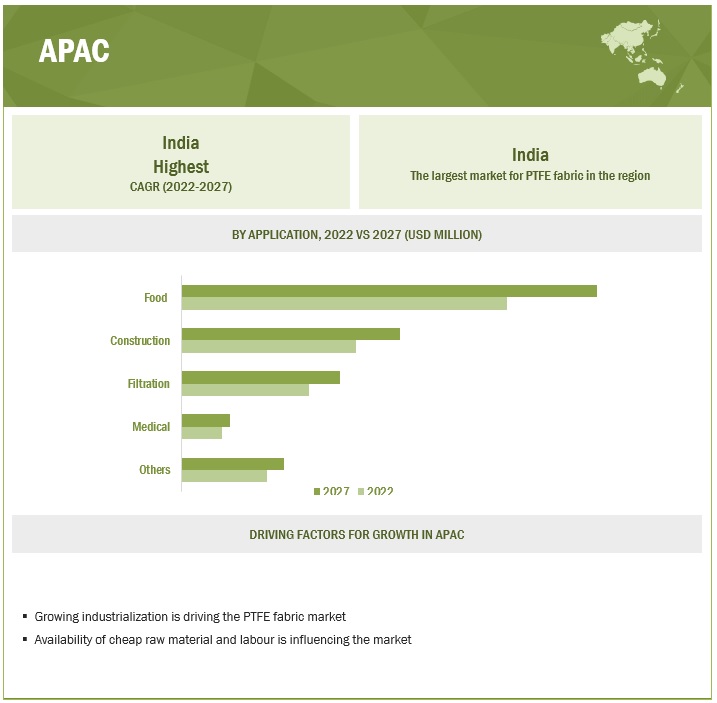

4.2 ASIA PACIFIC: PTFE FABRIC MARKET, BY END-USE INDUSTRY AND COUNTRY

FIGURE 11 CHINA LED PTFE FABRIC MARKET IN ASIA PACIFIC

4.3 PTFE FABRIC MARKET, BY TYPE

FIGURE 12 PTFE COATED FABRIC SEGMENT TO DOMINATE OVERALL MARKET

4.4 PTFE FABRIC MARKET, BY END-USE INDUSTRY

FIGURE 13 FOOD SEGMENT TO LEAD MARKET DURING FORECAST PERIOD

4.5 PTFE FABRIC MARKET, BY COUNTRY

FIGURE 14 INDIA TO BE FASTEST-GROWING MARKET DURING FORECAST PERIOD

5 MARKET OVERVIEW (Page No. - 41)

5.1 INTRODUCTION

5.2 MARKET DYNAMICS

FIGURE 15 MARKET DRIVERS, RESTRAINTS, CHALLENGES, AND OPPORTUNITIES

5.2.1 DRIVERS

5.2.1.1 High demand for PTFE fabric in automotive industry

5.2.1.2 Growing demand for PTFE-coated woven fabric as architectural fabric

5.2.1.3 Increasing consumption of composite fabric for industrial applications

5.2.2 RESTRAINTS

5.2.2.1 High cost of PTFE coated fabric compared with PVC coated fabric

5.2.2.2 Environmental impact of PTFE fabric manufacturing

5.2.3 OPPORTUNITIES

5.2.3.1 Increasing investments in food processing industry in emerging countries

5.2.3.2 Increasing opportunities from medical industry

TABLE 1 APPLICATION OF PTFE FIBERS IN MEDICAL TEXTILES

5.2.4 CHALLENGES

5.2.4.1 Volatility in raw material prices

TABLE 2 SPOT CRUDE PRICES (USD/BARREL)

5.2.4.2 Non-biodegradability of PTFE fabric

5.3 PORTER'S FIVE FORCES ANALYSIS

FIGURE 16 PORTER'S FIVE FORCES ANALYSIS: PTFE FABRIC MARKET

5.3.1 BARGAINING POWER OF SUPPLIERS

5.3.2 BARGAINING POWER OF BUYERS

5.3.3 THREAT OF SUBSTITUTES

5.3.4 THREAT OF NEW ENTRANTS

5.3.5 INTENSITY OF COMPETITIVE RIVALRY

TABLE 3 PTFE FABRIC MARKET: PORTER'S FIVE FORCES ANALYSIS

5.4 VALUE CHAIN ANALYSIS

5.4.1 RAW MATERIAL SUPPLIERS

5.4.2 MANUFACTURERS

5.4.3 DISTRIBUTORS

5.4.4 END CONSUMERS

FIGURE 17 PTFE FABRIC MARKET: VALUE CHAIN

5.5 ECOSYSTEM MAPPING

FIGURE 18 ECOSYSTEM OF PTFE FABRIC MARKET

TABLE 4 PTFE FABRIC MARKET: ECOSYSTEM

5.6 AVERAGE SELLING PRICE ANALYSIS

5.6.1 AVERAGE SELLING PRICE BASED ON REGION

FIGURE 19 AVERAGE SELLING PRICE BASED ON REGION (USD/KG)

5.6.2 AVERAGE SELLING PRICE BASED ON TYPE

TABLE 5 AVERAGE SELLING PRICES BASED ON TYPE (USD/KG)

5.6.3 AVERAGE SELLING PRICE BASED ON COMPETITORS

FIGURE 20 AVERAGE SELLING PRICE BASED ON COMPETITORS (USD/KG)

5.7 TRADE ANALYSIS

TABLE 6 IMPORT TRADE DATA FOR PTFE FOR TOP TEN COUNTRIES, 2017–2021 (USD THOUSAND)

TABLE 7 EXPORT TRADE DATA FOR PTFE FOR TOP TEN COUNTRIES, 2017–2021 (USD THOUSAND)

5.8 TECHNOLOGY ANALYSIS

5.8.1 QUICK FREEZE BELTS

5.8.2 ECO-FRIENDLY TEXTILE WITH LOW FRICTION PTFE

5.9 MACROECONOMIC DATA

5.9.1 US BUILDING AND CONSTRUCTION INVESTMENT

TABLE 8 ANNUAL VALUE OF CONSTRUCTION, 2011–2020 (USD BILLION)

5.10 TRENDS/DISRUPTIONS IMPACTING CUSTOMERS’ BUSINESSES

FIGURE 21 TRENDS IN PTFE FABRIC MARKET

5.11 KEY CONFERENCES & EVENTS IN 2022–2023

TABLE 9 PTFE FABRIC MARKET: DETAILED LIST OF CONFERENCES & EVENTS

5.12 KEY FACTORS AFFECTING BUYING DECISIONS

5.12.1 QUALITY

5.12.2 SERVICE

FIGURE 22 KEY BUYING CRITERIA

5.13 REGULATORY FRAMEWORK

5.13.1 ASIA PACIFIC

5.13.2 EUROPE

5.13.3 NORTH AMERICA

5.13.3.1 US

5.13.3.2 Canada

TABLE 10 STANDARDS FOR PTFE FLUOROPOLYMER RESINS

TABLE 11 LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

5.14 CASE STUDIES

5.14.1 W.L. GORE & ASSOCIATES

5.14.2 BIRDAIR

5.15 RECESSION IMPACT

5.16 PATENT ANALYSIS

5.16.1 METHODOLOGY

5.16.2 DOCUMENT TYPE

TABLE 12 TOTAL NUMBER OF PATENTS

5.16.3 PUBLICATION TRENDS

FIGURE 23 NUMBER OF PATENTS YEAR-WISE, 2011–2022

5.16.4 INSIGHTS

5.16.5 LEGAL STATUS OF PATENTS

FIGURE 24 PTFE FABRICS PATENT - LEGAL STATUS

5.16.6 JURISDICTION ANALYSIS

FIGURE 25 TOP JURISDICTION, BY DOCUMENT

5.16.7 TOP COMPANIES/APPLICANTS

FIGURE 26 TOP 10 COMPANIES/APPLICANTS WITH HIGHEST NUMBER OF PATENTS

5.16.7.1 Patents by W.L. Gore & Associates

TABLE 13 PATENTS BY W.L. GORE & ASSOCIATES

5.16.8 TOP 10 PATENT OWNERS (US) IN LAST 10 YEARS

TABLE 14 TOP TEN PATENT OWNERS

6 PTFE FABRIC MARKET, BY TYPE (Page No. - 65)

6.1 INTRODUCTION

FIGURE 27 PTFE COATED FABRIC ESTIMATED TO BE LARGEST SEGMENT DURING FORECAST PERIOD

TABLE 15 PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 16 PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 17 PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 18 PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

6.2 PTFE COATED FABRIC

6.3 NONWOVEN FABRIC

6.4 PTFE FIBER-MADE FABRIC

7 PTFE FABRIC MARKET, BY END-USE INDUSTRY (Page No. - 69)

7.1 INTRODUCTION

FIGURE 28 FOOD SEGMENT TO DOMINATE OVERALL MARKET DURING FORECAST PERIOD

TABLE 19 PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 20 PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 21 PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 22 PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

7.2 FOOD

7.3 CONSTRUCTION

7.4 FILTRATION

7.5 MEDICAL

7.6 OTHERS

7.6.1 PROTECTIVE CLOTHING

7.6.2 TRANSPORTATION

8 PTFE FABRIC MARKET, BY REGION (Page No. - 74)

8.1 INTRODUCTION

FIGURE 29 INDIA TO BE FASTEST-GROWING MARKET DURING FORECAST PERIOD

TABLE 23 PTFE FABRIC MARKET SIZE, BY REGION, 2018–2021 (USD MILLION)

TABLE 24 PTFE FABRIC MARKET SIZE, BY REGION, 2022–2027 (USD MILLION)

TABLE 25 PTFE FABRIC MARKET SIZE, BY REGION, 2018–2021 (TON)

TABLE 26 PTFE FABRIC MARKET SIZE, BY REGION, 2022–2027 (TON)

8.2 ASIA PACIFIC

FIGURE 30 ASIA PACIFIC: PTFE FABRIC MARKET SNAPSHOT

TABLE 27 ASIA PACIFIC: PTFE FABRIC MARKET SIZE, BY COUNTRY, 2018–2021 (USD MILLION)

TABLE 28 ASIA PACIFIC: PTFE FABRIC MARKET SIZE, BY COUNTRY, 2022–2027 (USD MILLION)

TABLE 29 ASIA PACIFIC: PTFE FABRIC MARKET SIZE, BY COUNTRY, 2018–2021 (TON)

TABLE 30 ASIA PACIFIC: PTFE FABRIC MARKET SIZE, BY COUNTRY, 2022–2027 (TON)

TABLE 31 ASIA PACIFIC: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 32 ASIA PACIFIC: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 33 ASIA PACIFIC: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 34 ASIA PACIFIC: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

TABLE 35 ASIA PACIFIC: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 36 ASIA PACIFIC: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 37 ASIA PACIFIC: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 38 ASIA PACIFIC: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

8.2.1 CHINA

8.2.1.1 Increased use in medical application driving market

TABLE 39 CHINA: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 40 CHINA: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 41 CHINA: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 42 CHINA: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

TABLE 43 CHINA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 44 CHINA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 45 CHINA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 46 CHINA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

8.2.2 JAPAN

8.2.2.1 Rising food and filtration industry to drive demand

TABLE 47 JAPAN: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 48 JAPAN: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 49 JAPAN: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 50 JAPAN: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

TABLE 51 JAPAN: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 52 JAPAN: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 53 JAPAN: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 54 JAPAN: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

8.2.3 INDIA

8.2.3.1 Urbanization and industrialization to fuel market growth

TABLE 55 INDIA: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 56 INDIA: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 57 INDIA: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 58 INDIA: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

TABLE 59 INDIA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 60 INDIA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 61 INDIA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 62 INDIA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

8.2.4 SOUTH KOREA

8.2.4.1 Large food processing industry to fuel demand for PTFE fabric

TABLE 63 SOUTH KOREA: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 64 SOUTH KOREA: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 65 SOUTH KOREA: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 66 SOUTH KOREA: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

TABLE 67 SOUTH KOREA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 68 SOUTH KOREA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 69 SOUTH KOREA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 70 SOUTH KOREA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

8.2.5 AUSTRALIA

8.2.5.1 Construction sector to drive market in Australia

TABLE 71 AUSTRALIA: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 72 AUSTRALIA: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 73 AUSTRALIA: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 74 AUSTRALIA: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

TABLE 75 AUSTRALIA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 76 AUSTRALIA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 77 AUSTRALIA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 78 AUSTRALIA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

8.2.6 REST OF ASIA PACIFIC

TABLE 79 REST OF ASIA PACIFIC: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 80 REST OF ASIA PACIFIC: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 81 REST OF ASIA PACIFIC: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 82 REST OF ASIA PACIFIC: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

TABLE 83 REST OF ASIA PACIFIC: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 84 REST OF ASIA PACIFIC: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 85 REST OF ASIA PACIFIC: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 86 REST OF ASIA PACIFIC: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

8.3 EUROPE

FIGURE 31 EUROPE: PTFE FABRIC MARKET SNAPSHOT

TABLE 87 EUROPE: PTFE FABRIC MARKET SIZE, BY COUNTRY, 2018–2021 (USD MILLION)

TABLE 88 EUROPE: PTFE FABRIC MARKET SIZE, BY COUNTRY, 2022–2027 (USD MILLION)

TABLE 89 EUROPE: PTFE FABRIC MARKET SIZE, BY COUNTRY, 2018–2021 (TON)

TABLE 90 EUROPE: PTFE FABRIC MARKET SIZE, BY COUNTRY, 2022–2027 (TON)

TABLE 91 EUROPE: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 92 EUROPE: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 93 EUROPE: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 94 EUROPE: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

TABLE 95 EUROPE: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 96 EUROPE: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 97 EUROPE: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 98 EUROPE: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

8.3.1 GERMANY

8.3.1.1 Construction and food industries play major role in driving demand

TABLE 99 GERMANY: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 100 GERMANY: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 101 GERMANY: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 102 GERMANY: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

TABLE 103 GERMANY: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 104 GERMANY: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 105 GERMANY: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 106 GERMANY: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

8.3.2 UK

8.3.2.1 Growing food industry to influence market

TABLE 107 UK: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 108 UK: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 109 UK: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 110 UK: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

TABLE 111 UK: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 112 UK: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 113 UK: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 114 UK: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

8.3.3 FRANCE

8.3.3.1 Investments in construction sector to drive market

TABLE 115 FRANCE: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 116 FRANCE: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 117 FRANCE: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 118 FRANCE: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

TABLE 119 FRANCE: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 120 FRANCE: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 121 FRANCE: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 122 FRANCE: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

8.3.4 ITALY

8.3.4.1 Pipeline construction projects to drive market for PTFE fabric

TABLE 123 ITALY: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 124 ITALY: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 125 ITALY: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 126 ITALY: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

TABLE 127 ITALY: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 128 ITALY: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 129 ITALY: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 130 ITALY: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

8.3.5 SPAIN

8.3.5.1 Growth in infrastructure and real estate sectors to propel demand

TABLE 131 SPAIN: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 132 SPAIN: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 133 SPAIN: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 134 SPAIN: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

TABLE 135 SPAIN: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 136 SPAIN: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 137 SPAIN: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 138 SPAIN: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

8.3.6 REST OF EUROPE

TABLE 139 REST OF EUROPE: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 140 REST OF EUROPE: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 141 REST OF EUROPE: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 142 REST OF EUROPE: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

TABLE 143 REST OF EUROPE: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 144 REST OF EUROPE: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 145 REST OF EUROPE: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 146 REST OF EUROPE: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

8.4 NORTH AMERICA

FIGURE 32 NORTH AMERICA: PTFE FABRIC MARKET SNAPSHOT

TABLE 147 NORTH AMERICA: PTFE FABRIC MARKET SIZE, BY COUNTRY, 2018–2021 (USD MILLION)

TABLE 148 NORTH AMERICA: PTFE FABRIC MARKET SIZE, BY COUNTRY, 2022–2027 (USD MILLION)

TABLE 149 NORTH AMERICA: PTFE FABRIC MARKET SIZE, BY COUNTRY, 2018–2021 (TON)

TABLE 150 NORTH AMERICA: PTFE FABRIC MARKET SIZE, BY COUNTRY, 2022–2027 (TON)

TABLE 151 NORTH AMERICA: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 152 NORTH AMERICA: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 153 NORTH AMERICA: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 154 NORTH AMERICA: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

TABLE 155 NORTH AMERICA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 156 NORTH AMERICA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 157 NORTH AMERICA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 158 NORTH AMERICA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

8.4.1 US

8.4.1.1 Presence of large chemical companies fueling demand for PTFE fabric for filtration

TABLE 159 US: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 160 US: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 161 US: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 162 US: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

TABLE 163 US: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 164 US: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 165 US: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 166 US: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

8.4.2 CANADA

8.4.2.1 Government initiatives for construction of skyscrapers and commercial hubs to increase use of PTFE fabric

TABLE 167 CANADA: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 168 CANADA: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 169 CANADA: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 170 CANADA: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

TABLE 171 CANADA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 172 CANADA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 173 CANADA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 174 CANADA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

8.4.3 MEXICO

8.4.3.1 Growing food industry to drive demand for PTFE fabric

TABLE 175 MEXICO: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 176 MEXICO: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 177 MEXICO: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 178 MEXICO: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

TABLE 179 MEXICO: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 180 MEXICO: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 181 MEXICO: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 182 MEXICO: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

8.5 SOUTH AMERICA

TABLE 183 SOUTH AMERICA: PTFE FABRIC MARKET SIZE, BY COUNTRY, 2018–2021 (USD MILLION)

TABLE 184 SOUTH AMERICA: PTFE FABRIC MARKET SIZE, BY COUNTRY, 2022–2027 (USD MILLION)

TABLE 185 SOUTH AMERICA: PTFE FABRIC MARKET SIZE, BY COUNTRY, 2018–2021 (TON)

TABLE 186 SOUTH AMERICA: PTFE FABRIC MARKET SIZE, BY COUNTRY, 2022–2027 (TON)

TABLE 187 SOUTH AMERICA: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 188 SOUTH AMERICA: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 189 SOUTH AMERICA: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 190 SOUTH AMERICA: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

TABLE 191 SOUTH AMERICA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 192 SOUTH AMERICA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 193 SOUTH AMERICA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 194 SOUTH AMERICA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

8.5.1 BRAZIL

8.5.1.1 Large food industry and government initiatives to stabilize construction industry to drive market

TABLE 195 BRAZIL: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 196 BRAZIL: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 197 BRAZIL: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 198 BRAZIL: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

TABLE 199 BRAZIL: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 200 BRAZIL: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 201 BRAZIL: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 202 BRAZIL: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

8.5.2 ARGENTINA

8.5.2.1 Focus on increasing export of food & beverage to drive market

TABLE 203 ARGENTINA: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 204 ARGENTINA: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 205 ARGENTINA: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 206 ARGENTINA: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

TABLE 207 ARGENTINA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 208 ARGENTINA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 209 ARGENTINA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 210 ARGENTINA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

8.5.3 REST OF SOUTH AMERICA

TABLE 211 REST OF SOUTH AMERICA: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 212 REST OF SOUTH AMERICA: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 213 REST OF SOUTH AMERICA: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 214 REST OF SOUTH AMERICA: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

TABLE 215 REST OF SOUTH AMERICA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 216 REST OF SOUTH AMERICA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 217 REST OF SOUTH AMERICA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 218 REST OF SOUTH AMERICA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

8.6 MIDDLE EAST & AFRICA

TABLE 219 MIDDLE EAST & AFRICA: PTFE FABRIC MARKET SIZE, BY COUNTRY, 2018–2021 (USD MILLION)

TABLE 220 MIDDLE EAST & AFRICA: PTFE FABRIC MARKET SIZE, BY COUNTRY, 2022–2027 (USD MILLION)

TABLE 221 MIDDLE EAST & AFRICA: PTFE FABRIC MARKET SIZE, BY COUNTRY, 2018–2021 (TON)

TABLE 222 MIDDLE EAST & AFRICA: PTFE FABRIC MARKET SIZE, BY COUNTRY, 2022–2027 (TON)

TABLE 223 MIDDLE EAST & AFRICA: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 224 MIDDLE EAST & AFRICA: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 225 MIDDLE EAST & AFRICA: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 226 MIDDLE EAST & AFRICA: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

TABLE 227 MIDDLE EAST & AFRICA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 228 MIDDLE EAST & AFRICA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 229 MIDDLE EAST & AFRICA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 230 MIDDLE EAST & AFRICA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

8.6.1 SAUDI ARABIA

8.6.1.1 New pipeline projects to influence market growth

TABLE 231 SAUDI ARABIA: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 232 SAUDI ARABIA: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 233 SAUDI ARABIA: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 234 SAUDI ARABIA: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

TABLE 235 SAUDI ARABIA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 236 SAUDI ARABIA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 237 SAUDI ARABIA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 238 SAUDI ARABIA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

8.6.2 UAE

8.6.2.1 Changing energy-mix to drive market

TABLE 239 UAE: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 240 UAE: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 241 UAE: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 242 UAE: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

TABLE 243 UAE: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 244 UAE: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 245 UAE: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 246 UAE: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

8.6.3 QATAR

8.6.3.1 PTFE fabric used in construction of stadiums

TABLE 247 QATAR: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 248 QATAR: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 249 QATAR: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 250 QATAR: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

TABLE 251 QATAR: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 252 QATAR: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 253 QATAR: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 254 QATAR: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

8.6.4 SOUTH AFRICA

8.6.4.1 Food segment to be largest and fastest-growing market for PTFE fabric

TABLE 255 SOUTH AFRICA: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 256 SOUTH AFRICA: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 257 SOUTH AFRICA: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 258 SOUTH AFRICA: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

TABLE 259 SOUTH AFRICA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 260 SOUTH AFRICA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 261 SOUTH AFRICA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 262 SOUTH AFRICA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

8.6.5 REST OF MIDDLE EAST & AFRICA

TABLE 263 REST OF MIDDLE EAST & AFRICA: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (USD MILLION)

TABLE 264 REST OF MIDDLE EAST & AFRICA: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (USD MILLION)

TABLE 265 REST OF MIDDLE EAST & AFRICA: PTFE FABRIC MARKET SIZE, BY TYPE, 2018–2021 (TON)

TABLE 266 REST OF MIDDLE EAST & AFRICA: PTFE FABRIC MARKET SIZE, BY TYPE, 2022–2027 (TON)

TABLE 267 REST OF MIDDLE EAST & AFRICA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 268 REST OF MIDDLE EAST & AFRICA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

TABLE 269 REST OF MIDDLE EAST & AFRICA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (TON)

TABLE 270 REST OF MIDDLE EAST & AFRICA: PTFE FABRIC MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (TON)

9 COMPETITIVE LANDSCAPE (Page No. - 163)

9.1 OVERVIEW

FIGURE 33 COMPANIES ADOPTED ACQUISITION AND EXPANSION AS KEY GROWTH STRATEGIES BETWEEN 2018 AND 2022

9.2 RANKING ANALYSIS OF KEY MARKET PLAYERS, 2022

FIGURE 34 RANKING OF TOP FIVE PLAYERS IN PTFE FABRIC MARKET, 2022

9.3 MARKET SHARE ANALYSIS

FIGURE 35 PTFE FABRIC MARKET SHARE, BY COMPANY (2022)

TABLE 271 PTFE FABRIC MARKET: DEGREE OF COMPETITION

9.4 REVENUE ANALYSIS OF TOP PLAYERS

TABLE 272 PTFE FABRIC MARKET: REVENUE ANALYSIS

9.5 MARKET EVALUATION MATRIX

TABLE 273 MARKET EVALUATION MATRIX

9.6 COMPANY EVALUATION MATRIX, 2022 (TIER 1)

9.6.1 STARS

9.6.2 EMERGING LEADERS

9.6.3 PERVASIVE PLAYERS

9.6.4 PARTICIPANTS

FIGURE 36 PTFE FABRIC MARKET: COMPANY EVALUATION MATRIX, 2022

9.7 START-UPS AND SMALL AND MEDIUM-SIZED ENTERPRISES (SMES) EVALUATION MATRIX

9.7.1 PROGRESSIVE COMPANIES

9.7.2 RESPONSIVE COMPANIES

9.7.3 DYNAMIC COMPANIES

9.7.4 STARTING BLOCKS

FIGURE 37 PTFE FABRIC MARKET: START-UPS AND SMES MATRIX, 2022

9.8 COMPANY END-USE INDUSTRY FOOTPRINT

9.9 COMPANY REGION FOOTPRINT

9.10 STRENGTH OF PRODUCT PORTFOLIO

FIGURE 38 STRENGTH PRODUCT PORTFOLIO

9.11 BUSINESS STRATEGY EXCELLENCE

FIGURE 39 BUSINESS STRATEGY EXCELLENCE

9.12 COMPETITIVE SCENARIO

9.12.1 NEW PRODUCT LAUNCHES

TABLE 274 NEW PRODUCT LAUNCHES, 2018–2022

9.12.2 DEALS

TABLE 275 DEALS, 2018—2022

9.12.3 OTHER DEVELOPMENTS

TABLE 276 OTHER DEVELOPMENTS, 2018–2022

10 COMPANY PROFILES (Page No. - 176)

10.1 KEY PLAYERS

(Business Overview, Products, Recent Developments, MnM View)

10.1.1 TACONIC

TABLE 277 TACONIC: COMPANY OVERVIEW

TABLE 278 TACONIC: PRODUCTS OFFERED

10.1.2 SAINT-GOBAIN PERFORMANCE PLASTICS

TABLE 279 SAINT-GOBAIN PERFORMANCE PLASTICS: COMPANY OVERVIEW

FIGURE 40 SAINT-GOBAIN PERFORMANCE PLASTICS: COMPANY SNAPSHOT

TABLE 280 SAINT-GOBAIN PERFORMANCE PLASTICS: PRODUCTS OFFERED

10.1.3 W.L. GORE & ASSOCIATES

TABLE 281 W.L. GORE & ASSOCIATES: COMPANY OVERVIEW

TABLE 282 W.L. GORE & ASSOCIATES: PRODUCTS OFFERED

TABLE 283 PRODUCT LAUNCHES

TABLE 284 DEALS

10.1.4 DAIKIN INDUSTRIES

TABLE 285 DAIKIN INDUSTRIES: COMPANY OVERVIEW

FIGURE 41 DAIKIN INDUSTRIES: COMPANY SNAPSHOT

TABLE 286 DAIKIN INDUSTRIES: PRODUCTS OFFERED

TABLE 287 DAIKIN INDUSTRIES: OTHERS

10.1.5 THE CHEMOURS COMPANY

TABLE 288 THE CHEMOURS COMPANY: COMPANY OVERVIEW

FIGURE 42 THE CHEMOURS COMPANY: COMPANY SNAPSHOT

TABLE 289 THE CHEMOURS COMPANY: PRODUCTS OFFERED

TABLE 290 THE CHEMOURS COMPANY: OTHERS

10.1.6 BIRDAIR

TABLE 291 BIRDAIR: COMPANY OVERVIEW

TABLE 292 BIRDAIR: PRODUCTS OFFERED

TABLE 293 BIRDAIR: OTHERS

10.1.7 CHUKOH CHEMICAL INDUSTRIES

TABLE 294 CHUKOH CHEMICAL INDUSTRIES: COMPANY OVERVIEW

TABLE 295 CHUKOH CHEMICAL INDUSTRIES: PRODUCTS OFFERED

TABLE 296 CHUKOH CHEMICAL INDUSTRIES: PRODUCT LAUNCHES

10.1.8 FIBERFLON

TABLE 297 FIBERFLON: COMPANY OVERVIEW

TABLE 298 FIBERFLON: PRODUCTS OFFERED

TABLE 299 FIBERFLON: PRODUCT LAUNCHES

10.1.9 SEFAR

TABLE 300 SEFAR: COMPANY OVERVIEW

TABLE 301 SEFAR: PRODUCTS OFFERED

10.1.10 W.F. LAKE CORPORATION

TABLE 302 W.F. LAKE CORPORATION: COMPANY OVERVIEW

TABLE 303 W.F. LAKE CORPORATION: PRODUCTS OFFERED

TABLE 304 W.F. LAKE CORPORATION: PRODUCT LAUNCHES

10.2 OTHER PLAYERS

10.2.1 FOTHERGILL GROUP

10.2.2 AETNA PLASTICS

10.2.3 SIFTEX EQUIPMENT COMPANY, INC

10.2.4 TEXTILES COATED INTERNATIONAL

10.2.5 ZHEJIANG KERTICE HI-TECH FLUOR-MATERIAL CO., LTD.

10.2.6 EDER

10.2.7 TOSS GMBH & CO. KG

10.2.8 TECHBELTl

10.2.9 ASAHI GLASS CO. LTD.

10.2.10 URJA FABRICS

10.2.11 HONDA SANGYO CO. LTD.

10.2.12 QINGDAO BOCHENG INDUSTRIAL CO. LTD.

10.2.13 CURBELL PLASTICS

10.2.14 OM INDUSTRIAL FABRICS

10.2.15 CS HYDE COMPANY

*Details on Business Overview, Products, Recent Developments, MnM View might not be captured in case of unlisted companies.

11 APPENDIX (Page No. - 204)

11.1 INSIGHTS FROM INDUSTRY EXPERTS

11.2 DISCUSSION GUIDE

11.3 KNOWLEDGESTORE: MARKETSANDMARKETS’ SUBSCRIPTION PORTAL

11.4 CUSTOMIZATION OPTIONS

11.5 RELATED REPORTS

11.6 AUTHOR DETAILS

Generating Response ...

Generating Response ...

Growth opportunities and latent adjacency in PTFE Fabric Market

General information on PTFE Fabric Market

Specific information on PTFE fabrics and its applications. Also would like to understand african markets