Vertical Injection Molding Machine Market by Machine Type (Hydraulic, All-Electric and Hybrid), Clamping Force (0-100 Tons, 101-200 Tons, 201-500 Tons and Above 500 Tons), Material (Plastic, Rubber, Metal), Application (Automotive, Medical & Healthcare, Consumer Goods), Automation and Region - Global Forecast to 2030

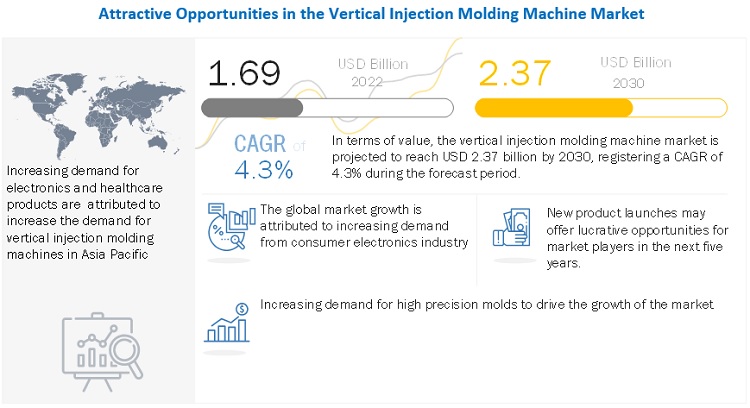

The vertical injection molding machine market is projected to reach USD 2.37 billion by 2030, at a CAGR of 4.3% from USD 1.69 billion in 2022. One of the major factors contributing to the growth of the vertical injection molding machine market is its specific utilization for insert molding and over molding applications. Also, the demand for high-precision molds is also driving the market.

To know about the assumptions considered for the study, Request for Free Sample Report

Market Dynamics

Driver: Utilization for insert molding and over-molding applications

In a vertical injection molding machine, it is easier to place the inserts or molding parts into the mold with less probability of misalignment. Both insert molding and over-molding cycles require finished product to be taken out after molding. With horizontal injection molding machine, this becomes difficult as it is against gravity. This increases the chances of damaged products. Therefore, for insert moldings and over-moldings vertical injection molding machines are preferred to produce precise finished products.

Restraints: High set-up and maintenance cost

A fully automatic vertical injection molding machine consists of a robotic system which helps in extracting the finished molds after the molding process. Due to high complexities and technological innovations, these systems are costlier than traditional vertical injection molding machine. In addition, it will also require a skilled man force to run the process efficiently. All these factors add up to the production cost resulting in high-cost final product.

Opportunities: Increasing medical injection molding industry

Plastic injection molding is a cost-effective and efficient means of making high-precision, high-accuracy, and high-quality medical and pharmaceutical products. From medical devices and equipment to laboratory tools and testing instruments, it's utilized to make components. Plastics are now widely used in modern industrial processes, due to advancements in material manufacturing techniques and technology. One of the major applications of vertical injection molding machines is in medical industry. The machines are widely used to produce medical molds with insert moldings and over-moldings. Development in medical injection molding industry will also grow the vertical injection molding machine market.

Challenges: Finished parts maybe damaged during removal by robots

In a horizontal molding machine, after the molding process the finished molds automatically fall out of the mold and are easily collected for further processing. But in case of vertical injection molding machine, since the process is carried on a vertical axis, the finished mold needs to be removed either by robots or manually to continue the next molding process. With the technological advancement, companies are now developing robotic systems to extract these molds to reduce the cycle time. However, during the extraction of these finished molds, there is high probability of these molds to sustain damage which could incur loss.

“Hydraulic was the largest machine type of vertical injection molding machine market in 2021, in terms of value”

The hydraulic vertical injection molding machine market accounted for the largest share, in terms of value, in 2021. This dominance is expected to continue during the forecast period owing to its enhanced performance and low maintenance cost. Also, the increasing demand from end-use industries such as automotive, consumer goods, and packaging is fueling the growth of the vertical hydraulic vertical injection molding machine market.

“Automotive was the largest application for vertical injection molding machine market in 2021, in terms of value”

The automotive application segment accounted for the largest share of the global vertical injection molding machine market, in terms of value, in 2021. The demand for vertical injection molding machines in the automotive application is expected to increase mainly because of the rise in vehicle production in APAC.

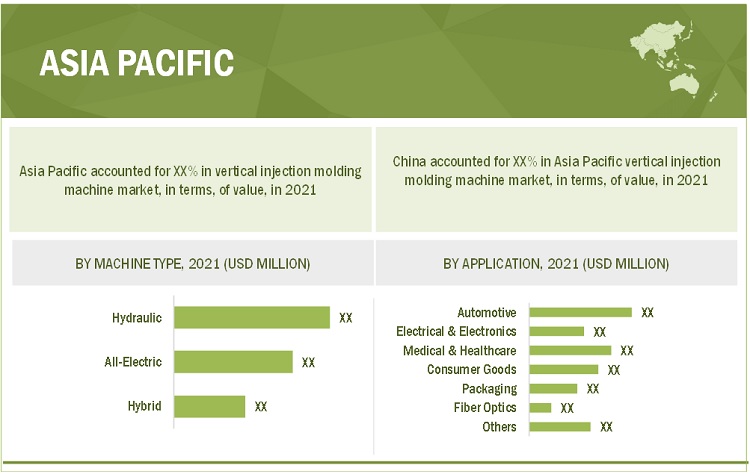

“Asia Pacific was the largest market for vertical injection molding machine in 2021, in terms of value.”

Asia Pacific is the largest vertical injection molding machine market and is projected to register the highest CAGR, in terms of volume, between 2022 and 2030. Economic growth in the region has led to high internal trade and domestic transportation of commodities and supplies. China and Japan are some of the largest automobile producers globally. These countries are competing to manufacture technologically advanced vehicles and are investing heavily in their research and development to develop high-precision parts. Furthermore, the boom of the electric vehicles market is further fueling the demand for automotive parts. This has increased the number of on-road commercial vehicles, thus driving the vertical injection molding machine market.

To know about the assumptions considered for the study, download the pdf brochure

Key Market Players

The key players in this market Sumitomo (SHI) Demag Plastics Machinery (Japan), Fanuc Corporation (Japan), Japan Steel Works (Japan), Nissei Plastic Industrial Co., Ltd (Japan), Toyo Machinery & Metal Co., Ltd (Japan), BOY Machines Inc. (US) , and Wittman Battenfeld Inc.(US). Continuous developments in the market—including new product launches, mergers & acquisitions, agreements, and expansions—are expected to help the market grow. Leading manufacturers of vertical injection molding machine market have opted for new product launches to sustain their market position.

Scope Of The Report

|

Report Metric |

Details |

|

Years considered for the study |

2017-2030 |

|

Base Year |

2021 |

|

Forecast period |

2022–2030 |

|

Units considered |

Volume (Units); Value (USD Million) |

|

Segments |

Machine Type, Clamping Force, Material, Application, Automation, and Region |

|

Regions |

Asia Pacific, North America, Europe, Middle East & Africa, and South America |

|

Companies |

The key players in this market are Sumitomo (SHI) Demag Plastics Machinery (Japan), Fanuc Corporation (Japan), Japan Steel Works (Japan), Nissei Plastic Industrial Co., Ltd (Japan), Toyo Machinery & Metal Co., Ltd (Japan) |

This report categorizes the global vertical injection molding machine market based on machine type, clamping force, material, application, automation, and region.

On the basis of machine type, the vertical injection molding machine market has been segmented as follows:

- Hydraulic

- All-Electric

- Hybrid

On the basis of clamping force, the vertical injection molding machine market has been segmented as follows:

- 0-50 ton

- 51-100 ton

- 101-200 ton

- 201-500 ton

- 501 ton & above

On the basis of material, the vertical injection molding machine market has been segmented as follows:

- Plastic

- Rubber

- Metal

- Ceramic

- Other

On the basis of application, the vertical injection molding machine market has been segmented as follows:

- Automotive

- Electrical & Electronics

- Medical

- Healthcare

- Consumer Goods

- Packaging

- Others

On the basis of automation form, the vertical injection molding machine market has been segmented as follows:

- Manual

- Automated

- Independent

- Into Production line

On the basis of region, the vertical injection molding machine market has been segmented as follows:

- Asia Pacific

- Europe

- North America

- Middle East & Africa

- South America

Frequently Asked Questions (FAQ):

What is the expected growth rate of vertical injection molding machine market?

The forecast period for vertical injection molding machine market in this study is 2022-2030. The vertical injection molding machine market is projected to grow at CAGR of 4.32%, in terms of value, during the forecast period.

Who are the major key players in vertical injection molding machine market?

Sumitomo (SHI) Demag Plastics Machinery (Japan), Fanuc Corporation (Japan), Japan Steel Works (Japan), Nissei Plastic Industrial Co., Ltd (Japan), Toyo Machinery & Metal Co., Ltd (Japan)

What is the average selling price trend for vertical injection molding machine market?

Prices are low in Asian countries (primarily China and India) compared to those in Europe and North America due to the low prices of raw materials and the availability of low-cost workforces in Asia Pacific. .

To speak to our analyst for a discussion on the above findings, click Speak to Analyst

Table of content

1 Introduction

1.1 Objective of the study

1.2 Market definition

1.3 Market Scope

1.3.1 Years considered for the study

1.4 Currency

1.5 Unit Considered

1.6 Stakeholders

2 Research Methodology

2.1 Research Data

2.2 Secondary Data

2.2.1 Key data from secondary sources

2.3 Primary Data

2.3.1 Key data from primary sources

2.3.2 Breakdown of Primary Interviews

2.4 Market Size Estimation

2.4.1 Bottom-Up Approach

2.4.2 Top-Down Approach

2.5 Data Triangulation

2.6 Assumptions

2.7 Limitations

3 Executive Summary

4 Premium Insights

4.1 Opportunities in Vertical Injection Molding Machine Market

4.2 Vertical Injection Molding Machine Market, By Machine Type

4.3 Vertical Injection Molding Machine Market, By Clamping Force

4.4 Vertical Injection Molding Machine Market, By Material

4.5 Vertical Injection Molding Machine Market, By Automation Form

4.6 Vertical Injection Molding Machine Market, By Application

4.7 Vertical Injection Molding Machine Market, By Region

5 Market Overview and Industry Trends

5.1 Introduction

5.2 Market Dynamics

5.2.1 Drivers

5.2.2 Restraints

5.2.3 Opportunities

5.2.4 Challenges

5.3 Supply Chain Analysis

5.3.1 Raw Material Manufacturing

5.3.2 Manufacturers

5.3.3 Distribution

5.3.4 End-Use Industry

5.4 Porter’s Five Forces Analysis

5.4.1 Threat of New Entrants

5.4.2 Threat of Substitutes

5.4.3 Bargaining Power of Buyers

5.4.4 Bargaining Power of Suppliers

5.4.5 Intensity of Competitive Rivalry

5.5 Average Selling Price

5.6 Industry Outlook

6 Vertical Injection Molding Machine Market, By Machine Type

6.1 Introduction

6.2 Hydraulic

6.3 All-Electric

6.4 Hybrid

7 Vertical Injection Molding Machine Market, By Clamping Force

7.1 Introduction

7.2 0-50 ton

7.3 51-100 ton

7.4 101-200 ton

7.5 201-500 ton

7.6 501 ton & above

8 Vertical Injection Molding Machine Market, By Material

8.1 Introduction

8.2 Plastic

8.3 Rubber

8.4 Metal

8.5 Ceramic

8.6 Other

9 Vertical Injection Molding Machine Market, By Application

9.1 Introduction

9.2 Automotive

9.3 Electrical & Electronics

9.4 Medical

9.5 Healthcare

9.6 Consumer Goods

9.7 Packaging

9.8 Others

10 Vertical Injection Molding Machine Market, By Automation Form

10.1 Introduction

10.2 Manual

10.3 Automated

10.3.1 Independent

10.3.2 Into Production line

11 Vertical Injection Molding Machine Market, By Region

11.1 Introduction

11.2 Asia Pacific

11.2.1 China

11.2.2 India

11.2.3 Japan

11.2.4 South Korea

11.2.5 Rest of Asia Pacific

11.3 North America

11.3.1 U.S.

11.3.2 Canada

11.3.3 Mexico

11.4 Europe

11.4.1 Germany

11.4.2 France

11.4.3 Italy

11.4.4 U.K.

11.4.5 Rest of Europe

11.5 Middle East & Africa

11.5.1 Egypt

11.5.2 Saudi Arabia

11.5.3 South Africa

11.5.4 Rest of Middle East & Africa

11.6 South America

11.6.1 Brazil

11.6.2 Argentina

11.6.3 Rest of South America

12 Competitive Landscape

12.1 Introduction

12.2 Market Share Analysis

12.3 Company Evaluation Quadrant

12.4 Competitive Situation & Trends

12.4.1 New Product Launches

12.4.2 Contracts & Agreements

12.4.3 Partnerships & Collaborations

12.4.4 Joint Ventures

12.4.5 Expansions

13 Company Profile

13.1 Sumitomo (SHI) Demag

13.1.1 Business Overview

13.1.2 Products Offered

13.1.3 Recent Development

13.1.4 MnM View

13.1.4.1 Key Strengths

13.1.4.2 Strategic choices made

13.1.4.3 Threat from competition

13.2 Fanuc Corporation

13.3 Japan Steel Works

13.4 Nissei Plastic Industrial Co., Ltd.

13.5 Toyo Machinery & Metal Co., Ltd.

13.6 Sodick Co., Ltd.

13.7 Dr. Boy GmbH & Co. KG

13.8 Engel Machinery Inc.

13.9 Wittman Battenfeld Inc

13.10 Niigata Machine Techno

13.11 List of other key market players

14 Appendix

14.1 Insights from Industry Experts

14.2 Discussion Guide

14.3 Related Reports

The study involved four major activities to estimate the size of vertical injection molding machine market. Exhaustive secondary research was done to collect information on the market, the peer market, and the parent market. The next step was to validate these findings, assumptions, and sizing with industry experts across the value chain through primary research. Both top-down and bottom-up approaches were employed to estimate the complete market size. Thereafter, the market breakdown and data triangulation procedures were used to estimate the market size of the segments and subsegments.

Secondary Research

In the secondary research process, various secondary sources have been referred to for identifying and collecting information for this study. These secondary sources include annual reports, press releases, investor presentations of companies, white papers, certified publications, trade directories, certified publications, articles from recognized authors, gold standard and silver standard websites, and databases.

Secondary research has been used to obtain key information about the value chain of the industry, monetary chain of the market, the total pool of key players, market classification and segmentation according to industry trends to the bottom-most level, and regional markets. It was also used to obtain information about the key developments from a market-oriented perspective.

Primary Research

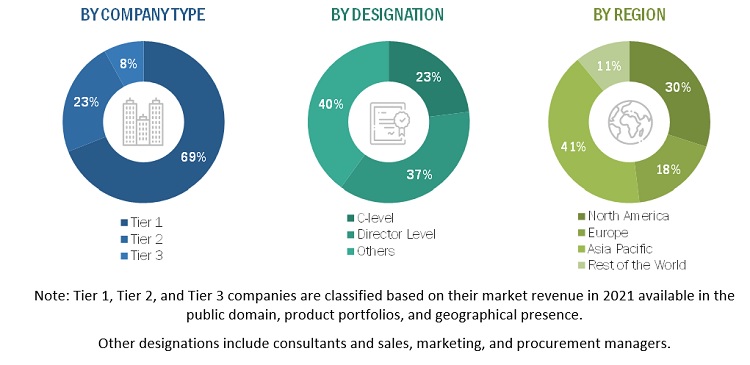

The vertical injection molding machine market comprises several stakeholders in the value chain, which include raw material suppliers, manufacturers, distributors, and end users. Various primary sources from the supply and demand sides of the vertical injection molding machine market have been interviewed to obtain qualitative and quantitative information.

The primary interviewees from the demand side include key opinion leaders in end-use sectors. The primary sources from the supply side include manufacturers, associations, and institutions involved in the vertical injection molding machine industry.

The breakdown of profiles of the primary interviewees is illustrated in the figure below:

To know about the assumptions considered for the study, download the pdf brochure

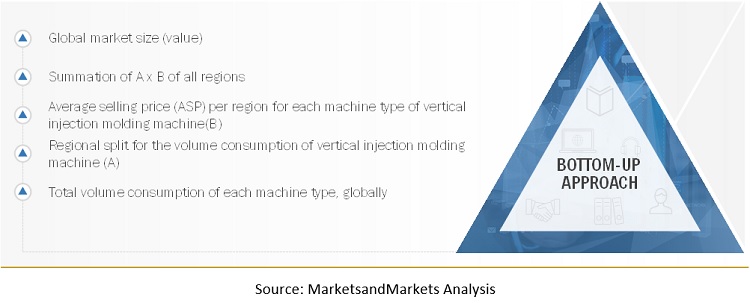

Market Size Estimation

The top-down and bottom-up approaches have been used to estimate and validate the size of the vertical injection molding machine market.

- The key players in the industry have been identified through extensive secondary research.

- The supply chain of the industry has been determined through primary and secondary research.

- All percentage shares, splits, and breakdowns have been determined using secondary sources and verified through primary sources.

- All possible parameters that affect the markets covered in this research study have been accounted for, viewed in extensive detail, verified through primary research, and analyzed to obtain the final quantitative and qualitative data.

- The research includes the study of reports, reviews, and newsletters of the key market players, along with extensive interviews for opinions with leaders such as directors and marketing executives.

Vertical Injection Molding Machine Market: Bottom-Up Approach 1

To know about the assumptions considered for the study, Request for Free Sample Report

Data Triangulation

After arriving at the total market size from the estimation process explained above, the overall market has been split into several segments and sub-segments. To complete the overall market engineering process and arrive at the exact statistics for all the segments and sub-segments, the data triangulation and market breakdown procedures have been employed, wherever applicable. The data has been triangulated by studying various factors and trends from both the demand and supply sides. Along with this, the market size has been validated by using both the top-down and bottom-up approaches and primary interviews. Hence, for every data segment, there have been three sources—top-down approach, bottom-up approach, and expert interviews. The data was assumed correct when the values arrived from the three sources matched.

Report Objectives

- To define, describe, and forecast the size of the vertical injection molding machine market, in terms of value and volume

- To provide detailed information regarding the major factors (drivers, opportunities, restraints, and challenges) influencing the growth of the market

- To estimate and forecast the market size based on machine type, clamping force, material, application, automation and region

- To forecast the size of the market with respect to major regions, namely, Europe, North America, Asia Pacific, and Middle East & Africa, and South America along with their key countries

- To strategically analyze micromarkets1 with respect to individual growth trends, prospects, and their contribution to the overall market

- To analyze opportunities in the market for stakeholders and provide a competitive landscape of market leaders

- To track and analyze recent developments such as expansions, new product launches, partnerships & agreements, and acquisitions in the market

- To strategically profile key market players and comprehensively analyze their core competencies2

Available Customizations

Along with the given market data, MarketsandMarkets offers customizations according to the company’s specific needs. The following customization options are available for the report:

Regional Analysis

Further breakdown of a region with respect to a particular country or additional application

Company Information

Detailed analysis and profiles of additional market players

Growth opportunities and latent adjacency in Vertical Injection Molding Machine Market