UV Tapes Market By Product Type (Polyolifin UV Tapes, Polyvinylchloride UV Tapes , Polyethylene Terephthalate, Other Product Types), Application (Wafer Dicing, Back grinding, Electronics Assembly, Other Applications), End-use Industry (Consumer Electronics, Semiconductors, Automotive, Other End-use Industries), and Region - Global Forecasts To 2030

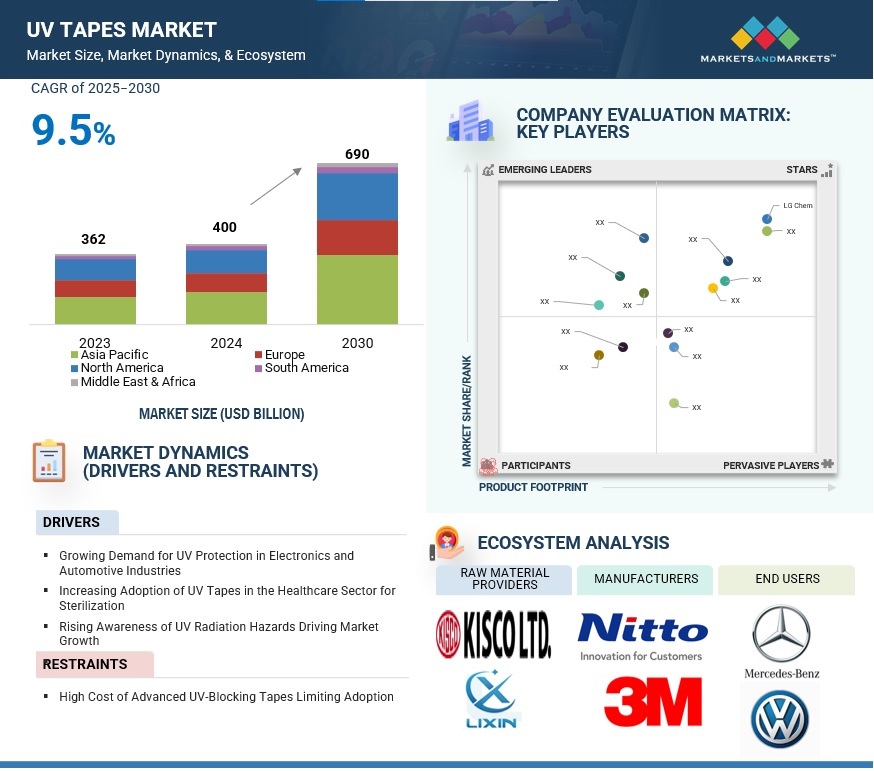

The UV Tapes market is projected to grow from USD 400 million in 2024 to USD 690 million by 2030, at a CAGR of 9.5% between 2025 and 2030. The demand from growing industries such as electronics, automotive, and healthcare is one of the main factors that drive demand for UV tapes in the market. Sensitive electronic parts are protected during manufacturing and storage with UV tapes. In addition, UV protection for several other components is available in the automotive industry, including headlights and windshields. Increasingly, the healthcare sector also uses UV tapes for facilities such as sterilization and protection of medical devices. Moreover, the growing awareness regarding the adverse effects of UV radiations, along with the demand for more and better efficient materials for ultraviolet blocking, has resulted in an increased adoption of UV tapes in different applications.

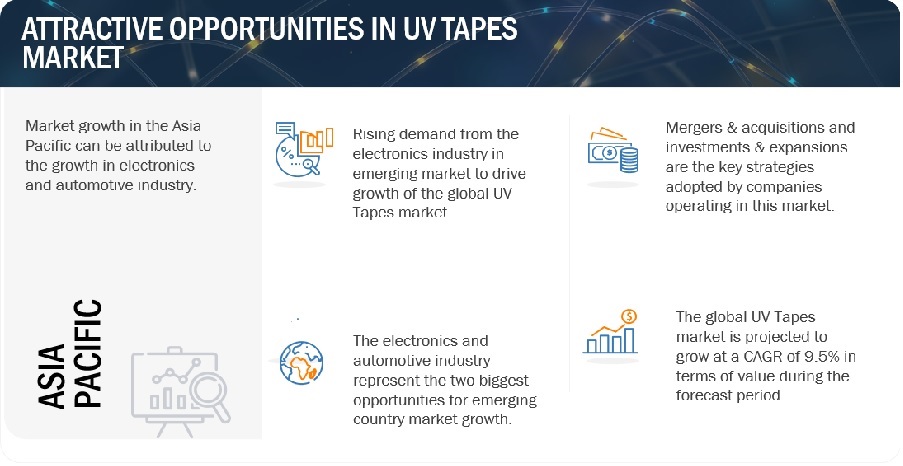

Attractive Opportunities in the UV Tapes Market

Source: Interviews with Experts, Secondary Sources, and MarketsandMarkets Analysis

Source: Interviews with Experts, Secondary Sources, and MarketsandMarkets Analysis

To know about the assumptions considered for the study, Request for Free Sample Report

Source: Expert Interviews, Secondary Sources, and MarketsandMarkets Analysis

Source: Expert Interviews, Secondary Sources, and MarketsandMarkets Analysis

UV Tapes Market Dynamics

Driver: Growing Awareness of UV Radiation Hazards

An increase in awareness about the adverse effects of UV radiation is one of the leading factors driving the UV tapes market. As consumers and industries become more aware of the risks associated with prolonged exposure to UV, the demand for UV-blocking solutions to protect sensitive materials, components, and workers will increase. Electronics, automotive, healthcare, and packaging industries are some of the sectors increasingly adopting UV tapes to prevent UV damage inflicted on products and ensure safety. Companies are becoming more concerned about the adverse health effects of UV radiations, such as skin and eye damage caused by UV rays, which in turn will influence companies to use UV tapes during the manufacturing process, product storage, and protection, eventually triggering further growth across the market.

Restraints: High Costs of Advanced UV-Blocking Tapes

High costs of advanced UV-blocking tapes are the major restraints in the industry- especially concerning particular cost and sensitive industries. Premium UV tapes include special protection characteristics such as superior UV filtering, high durability, and special adhesive properties in comparison to normal equivalents. Thus, they densely differ from the construction of small companies or firms whose budgets are confined such as construction or manufacturing in emerging countries. The costs of such high-quality tapes may inhibit their application, particularly in those cases where other options for UV protection, which are low in price or of less efficacy, are available. Hence, cost remains one of the most critical constraints to their usage in specific markets.

Opportunity: Expansion of UV Tape Applications

A quite significant area is renewable energy, in which UV tapes are used for solar panel manufacturing to protect sensitive components from UV damage, thus improving the life and efficiency of the panels. Moreover, the packaging industry is turning to UV tape to protect products against UV damage during their transport and storage, providing quality and prolonging shelf life. The increasing requirements of all these industries for better protection against UV radiation will lead to an increase in demand for such specialized UV tape and thus stimulate innovation as well as new markets for such products.

Challenges: Compliance with safety standards and certifications

Having different standards of safety and certifications is a major challenge faced by manufacturers in this UV tapes market. Since the regions vary on the areas of UV protection regulations, they make it difficult for manufacturers to attempt a global outreach. Among other things, a lot of certifications need to be acquired before UV tapes can be declared to meet safety requirements such as those by ISO or ANSI. Such compliance would go a long way in assuring the reliability of the product and safety for the consumer. The certifications now involved issue a high cost of acquisition and time, which makes the process cumbersome and prevents product market entry and adoption in certain regions.

UV Tapes Market Ecosystem

The ecosystem of the UV tapes market consists of the manufacturers, suppliers, distributors, and end-users. The key players include tape producers, raw material suppliers, for instance, UV-sensitive resins and adhesives, as well as packaging companies. Distributors play a critical role in the availability of UV tapes to various industries including electronics, automotive, medical devices, and packaging. Assemble users, for example, manufacturers of electronic components, automotive parts, and display technologies, that depend on UV tapes for applications including bonding, masking, and protection against damage during assembly or transportation would also be included in the end-user’s category. These factors, coupled with advances in technology, regulatory standards, and rising demand from industries that require high-performance adhesive solutions with UV-curing capabilities, all influence the market.

By type, Polyolefin UV tapes is one of the fastest growing type for UV Tapes market in terms of value

UV tapes made of polyolefin are one of the fastest-growing types in the UV tapes market because of their outstanding performance and cost-effectiveness. These tapes can offer tremendous UV protection and are therefore most suited for industries such as electronics, automotive, and packaging. Polyolefins are lightweight, durable, and resistant to environmental factors, thus enabling long-life and high-efficiency products that need UV protection. Polyolefin UV tapes are also versatile. They are strongly adhered to surfaces but supplied flexibility. It is driving increasing popularity in the industry, which is looking for reliable, high-performance UV blocking at a competitive price, adding to the growth of the market.

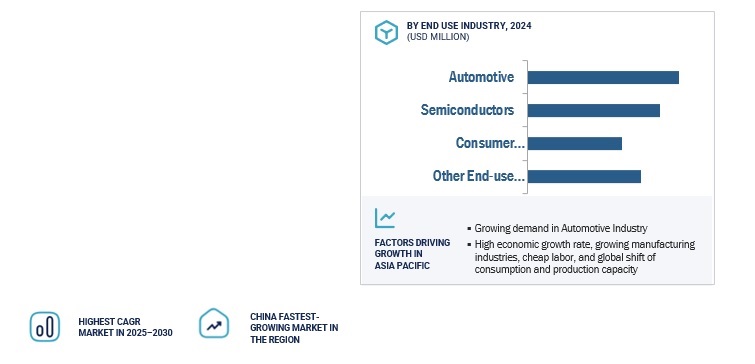

Consumer electronics segment is the fastest growing segment of UV Tapes market by end use industry in terms of value

It is the consumer electronics segment that is the fastest growing segment in the market for UV tapes, primarily because of the growing need for UV protection in equipment. As electronic products such as smartphones, tablets, and displays become more advanced, they will certainly be subject to other sensitive components during their manufacturing, storage, and transportation - all of which could result in UV damage without the necessary precautions. UV tapes help to keep these components free from discoloration, degradation, and loss of performance, all of which can arise from exposure to UV radiation. Another catalyst augmenting the growth of UV tapes in consumer electronics is the growing trend of wearable electronics and smart devices.

Asia Pacific is the one of the largest markets for UV Tapes market

Asia Pacific is one of the largest markets for UV tapes due to rapid industrialization, important manufacturing sectors, and increasing demand for UV protection in various industries. In this regard, countries such as China, Japan, and India act as major drivers of the market. The electronics, automotive, and packaging industries are all experiencing substantial growth in this region. Moreover, the thriving consumer electronics market in the region, along with the rapidly expanding renewable energy sectors such as solar power, increases the demand for UV tapes. Stricter safety rules and improving awareness of UV radiation protection also help the cause of UV tapes. They are also cost-effective and have a variety of applications to create popularity for UV tapes in this highly speeding region.

To know about the assumptions considered for the study, download the pdf brochure

Key Market Players

3M(US), Nitto Denko Corporation(Japan), Adwill Global(LINTEC Corporation)(Japan), Mitsui Chemicals(Japan), Furukawa Electric Co., Ltd.(Japan), Denka Company Limited(Japan) are the key players in the global UV Tapes market.

3M is a manufacturer and distributor of industrial products and solutions. Its portfolio of products includes advanced materials, display materials and systems, home care, home improvement, stationery and office, personal safety, roofing granules, closure and masking systems and others. 3M also offers various solutions such as medical, oral care, consumer health care, food safety, health information systems. It serves customers in various industries such as automotive, electronics, health care, safety, energy and consumer. The company has converting and manufacturing facilities in the Americas, Asia Pacific, Europe, the Middle East and Africa. 3M is headquartered in St. Paul, Minnesota, the US.

Recent Developments in UV Tapes Market

- In May 2022, to secure a steady supply of tape for semiconductor processes, Furukawa Electric Co., Ltd. Announced its plans to invest approximately JPY 7.0 Billion to boost the manufacturing capacity at the Mie Works. Operations are scheduled to begin in April 2025.

- In June 2021, Henkel declared that it is increasing its production capabilities and UV acrylic hotmelt pressure-sensitive adhesives product line (PSA). The decision is consistent with the company's strategic focus on sustainability and would help in resolving capacity issues that it had previously encountered along with rising demand for UV-curable PSAs.

To speak to our analyst for a discussion on the above findings, click Speak to Analyst

Frequently Asked Questions (FAQs):

What are the factors driving the growth of the UV Tapes market?

The growing consumer electronics market.

What are the major end-use industries for UV Tapes?

The major applications of UV Tapes are consumer electronics, semiconductors, and automotive.

Who are the major manufacturers of UV Tapes?

Nitto Denko Corporation (Japan), 3M Company (US), Adwill Global (LINTEC Corporation) (Japan), Mitsui Chemicals (Japan), Furukawa Electric Co., Ltd. (Japan), and Denka Company Limited (Japan) are the key players in the global UV Tapes market.

What are the reasons behind UV Tapes gaining market share?

UV Tapes are gaining market share due to increasing demand from the Asia Pacific region.

Which is the fastest growing region in the UV Tapes market?

Asia Pacific is the fastest growing region in the UV Tapes market.

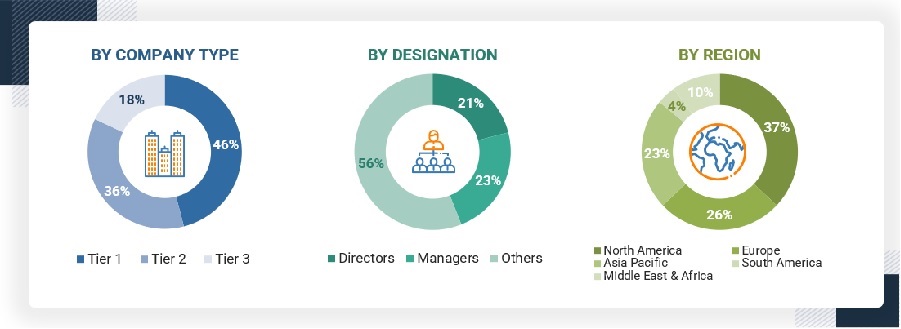

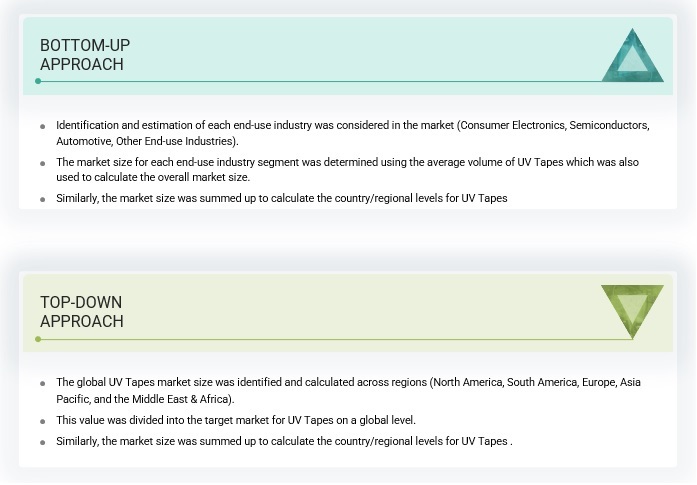

The study involved four major activities in order to estimating the current size of the UV Tapes market. Exhaustive secondary research conducted to gather information on the market. The next step was to conduct primary research to validate these findings, assumptions, and sizing with the industry experts across the value chain. Both top-down and bottom-up approaches were used to estimate the total market size. The market size of segments and subsegments was then estimated using market breakdown and data triangulation.

Secondary Research

Secondary sources include annual reports of companies, press releases, investor presentations, white papers, articles by recognized authors, and databases, such as D&B, Bloomberg, and Factiva; and publications and databases from associations, including The Pressure Sensitive Tape Council (PSTC), The European Adhesive Tape Association (ETAD), The International Organization for Standardization (ISO), The American National Standards Institute (ANSI).

Primary Research

Extensive primary research was carried out after gathering information about UV Tapes market through secondary research. In the primary research process, experts from the supply and demand sides have been interviewed to obtain qualitative and quantitative information and validate the data for this report. Questionnaires, emails, and telephonic interviews were used to collect primary data. Primary sources from the supply side include industry experts, such as chief executive officers (CEOs), vice presidents (VPs), marketing directors, technology and innovation directors, and related key executives from various key companies and organizations operating in the UV Tapes market. Primary interviews were conducted to elicit information such as market statistics, revenue data collected from the products and services, market breakdowns, market size estimations, market forecasting, and data triangulation. Primary research also assisted in comprehending the various trends associated to product type, application, end – use industry, and region.

The breakup of Primary Research:

To know about the assumptions considered for the study, download the pdf brochure

UV TAPES MANUFACTURERS

|

UV Tapes Manufaturers |

|

|

3M |

Mitsui Chemicals |

|

Nitto Denko Corporation |

Furukawa Electric Co., Ltd. |

|

Adwill Global (Lintec Corporation) |

Sumitomo Bakelite Co., Ltd. |

UV Tapes Market Size Estimation

The following information is part of the research methodology used to estimate the size of the UV Tapes market. The market sizing of the UV Tapes market was undertaken from the demand side. The market size was estimated based on market size for UV Tapes in various technology.

Global UV Tapes Market Size: Bottom-Up Approach and Top-Down Approach

To know about the assumptions considered for the study, Request for Free Sample Report

Data Triangulation

After arriving at the overall market size, the market has been split into several segments. To complete the overall market engineering process and arrive at the exact statistics for all segments, the data triangulation and market breakdown procedures have been employed, wherever applicable. The data was triangulated by studying various factors and trends from the demand and supply sides. Along with this, the market size was validated using both the top-down and bottom-up approaches.

Market Definition

UV tapes are specialized adhesive tapes that have a purpose to block or absorb ultraviolet (UV) light. These tapes are used in areas where there is a requirement for UV protection such as electronics, medical devices, automotive, construction, and packaging industries. The use of UV tape could be to shield UV-sensitive components from radiation.

Key Stakeholder

- End User

- Raw Material Suppliers

- Senior Management

- Procurement Department

Report Objectives:

- To define, describe, segment, and forecast the size of the UV tapes market based on width, type, end – use industry, and region.

- To forecast the market size of segments with respect to various regions, including North America, Europe, Asia Pacific, South America, Middle East & Africa, along with major countries in each region

- To identify and analyze key drivers, restraints, opportunities, and challenges influencing the growth of the UV tapes market

- To analyze technological advancements and product launches in the market

- To strategically analyze micromarkets, with respect to their growth trends, prospects, and their contribution to the market

- To identify financial positions, key products, and key developments of leading companies in the market

- To provide a detailed competitive landscape of the market, along with market share analysis

- To provide a comprehensive analysis of business and corporate strategies adopted by the key players in the market

- To strategically profile key players in the market and comprehensively analyze their core competencies

Available Customizations:

MarketsandMarkets offers the following customizations for this market report:

- Additional country-level analysis of the UV tapes market

- Profiling of additional market players (up to 5)

Product Analysis

- Product matrix, which gives a detailed comparison of the product portfolio of each company in the UV tapes market

Growth opportunities and latent adjacency in UV Tapes Market