PVC Adhesive Market by Type (Solvent-based, Water-based, Hot-melt, Reactive , Other Types), Application (Residential, Commercial, Industrial), End-use Industry (Construction, Automotive, Industrial Manufacturing, Other End-use Industries), and Region (2025-2030)

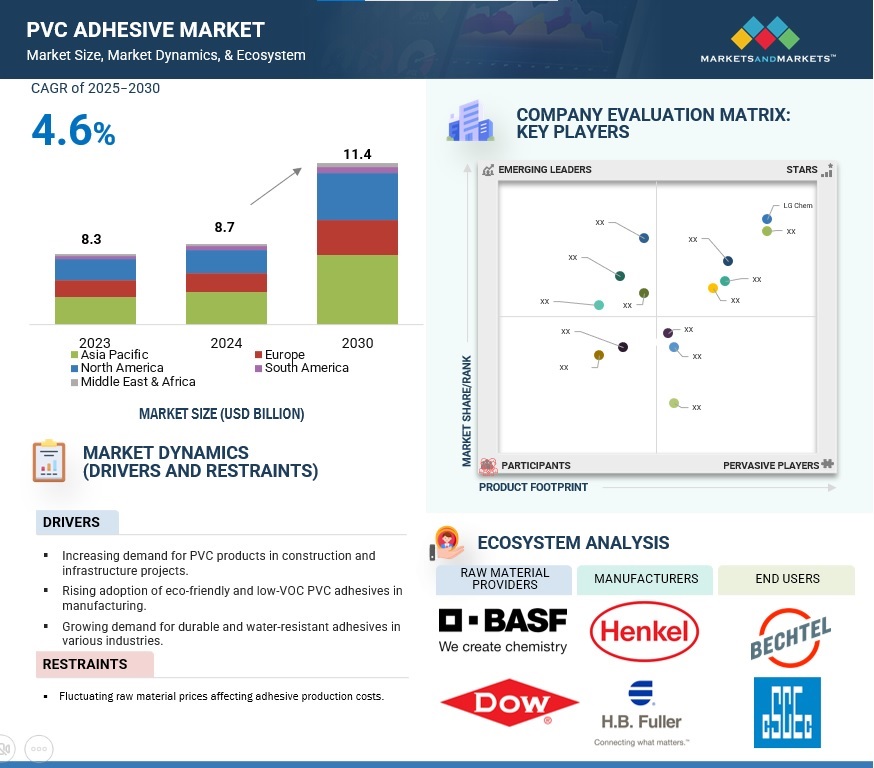

The PVC adhesive market is projected to grow from USD 8.7 billion in 2024 to USD 11.4 billion by 2030, at a CAGR of 4.6% between 2025 and 2030. The PVC Adhesives Market mainly includes the bonding agents designed for the use of diverse applications in industries like construction, automotive, plumbing, and packaging with polyvinyl chloride (PVC) materials. These bonds are known for their strength, durable bonding with high resistance to moisture, chemicals, and temperature change, which makes them suitable for appliances like PVC pipes, windows, and floors. Major driving factors include speedy growth in infrastructure development, increasing demand for PVC-based products, and improved adhesive technology for sustainable and efficient solutions. The number of high-performance adhesives required in various end-use applications has also escalated the growth of the PVC adhesives market.

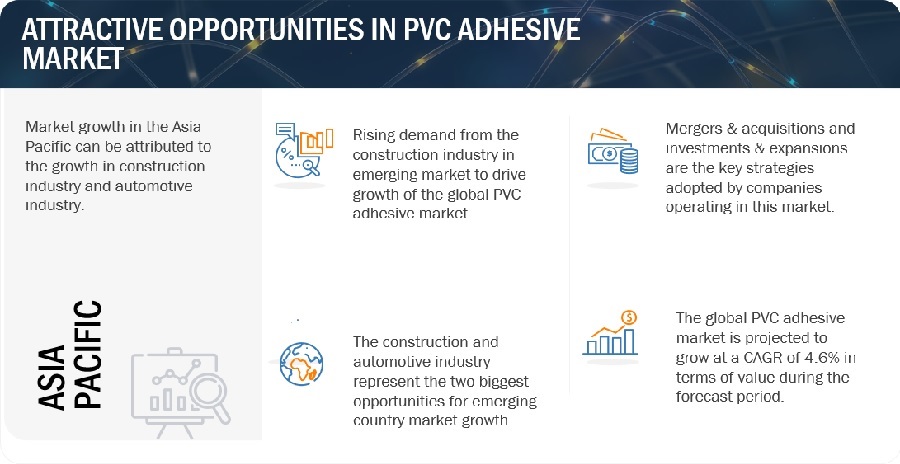

Attractive Opportunities in the PVC Adhesive Market

Source: Interviews with Experts, Secondary Sources, and MarketsandMarkets Analysis

Source: Interviews with Experts, Secondary Sources, and MarketsandMarkets Analysis

To know about the assumptions considered for the study, Request for Free Sample Report

Source: Expert Interviews, Secondary Sources, and MarketsandMarkets Analysis

Source: Expert Interviews, Secondary Sources, and MarketsandMarkets Analysis

PVC Adhesive Market Dynamics

Driver: Urbanization and Infrastructure Development

The increasing demand for PVC products, with regard to pipes, flooring, and windows, grows rapidly in developing economies due to their use as a major player in construction and infrastructure development. Increased demand for durable yet cost-effective bonding solutions for materials made from PVC arises with urban expansion, new residential, commercial, and industrial developments. PVC adhesives develop strength, add water resistance, and durability for such applications, making them crucial in modern construction. The rapid pace of urban development drives this market further by bringing builders and contractors looking for better, more reliable, and more efficient market adhesives to meet with the ever-increasing demand for high-performance PVC-based products.

Restraints: Environmental Concerns

The rising environmental issues related to solvent-based adhesives are a major constraint and limit the consumption of PVC adhesives. Solvent-based adhesives contain volatile organic compounds (VOCs), which have been set forth to cause air pollutions as well as health risks, thereby resulting in the imposition of stricter environmental regulations. These constraints, therefore, limit the growth of solvent-based PVC adhesives, as the manufacturers incur higher production costs due to regulatory requirements and the development of sustainable alternatives. Emerging governmental as well as industrial trends therefore favor green and sustainable propositions, which create a demand for either low-VOC or water-based adhesives. The above issues thus form a challenge point in the future for market growth, along with consistent conformity with sustainable standards.

Opportunity: Growth Opportunities for Smart PPE in Asia-Pacific's Industrial Sectors

The rapid growth of infrastructural and construction activities in developing countries, especially in the Asia-Pacific region, presents lucrative opportunities for the PVC adhesive market. As cities become larger, the demand for long-lasting but cheaper PVC products such as pipes, floors, and windows, will require strong bonding solutions. A large middle-class population with government investment in housing, commercial, and other infrastructure projects increases this demand. These applications require PVC adhesives, which presents a strong opportunity for manufacturers in terms of meeting construction requirements for developing economies.

Challenges: Regulatory Compliance

Strict environmental and safety regulations concerning chemicals in adhesives have caused a major challenge for the PVC adhesive market in developed markets. Such regulations do not allow the usage of some chemicals like volatile organic compounds (VOCs), which are mostly present in solvent-based adhesives. Compliance with these regulations calls for heavy investment in research and development by manufacturers to make them develop safer, eco-friendly alternatives and incur high production costs and time. Furthermore, different regions have different regulations which complicate product development and market entry, restricting growth in some segments of the PVC adhesive market.

PVC Adhesive Market Ecosystem

The ecosystem of the PVC adhesives market composes tied relationships between different connected stakeholders who are all-important contributors in manufacturing, distributing, and, ultimately consuming these adhesives. Raw material suppliers such as BASF, Dow Chemical, and SABIC conceptualize the processes by which they source base chemicals and resins (PVC, solvents, and polymers required for making adhesives) but are very different from that of Henkel, 3M, and H.B. Fuller, which manufacture different types of adhesives for various industries, including construction, automotive, and plumbing. Distributors do just that-distribute-the adhesive products to the end users: contract subsidy home DIYs to the industry requiring durable bonding. Regulatory bodies. EPA and ECHA have formulations, thus creating safety and environmental standards that affect product development with a push toward eco-friendly and low-VOC adhesives. R&D institutions also continuously innovate and make advancements in areas such as adhesive performance and sustainability. Environmental advocates lend their voices to encourage green substitutions further driving the demand for more sustainable adhesive solutions. These then make complex entities together in a very dynamic, ever-changing adhesion PVC market capable of adapting to industrial needs and environmental considerations.

By type, water based is one of the fastest growing type for PVC adhesives market in terms of value

Water-borne PVC adhesives are by far the fastest-moving adhesive type in the terms of value. The increasing demand for low-VOC and eco-friendly adhesives that meet stringent environmental regulations has primarily been responsible for this increase. Water-based adhesives significantly mitigate health and environmental risks, dry quickly, and exhibit a highly safe application process. Such adhesives find use in various industries such as construction, automotive, and packaging, where sustainability and efficiency are top priorities. Water-borne adhesives will continue to grow and thus remain one of the market drivers for the foreseeable future as industries move to greener alternatives.

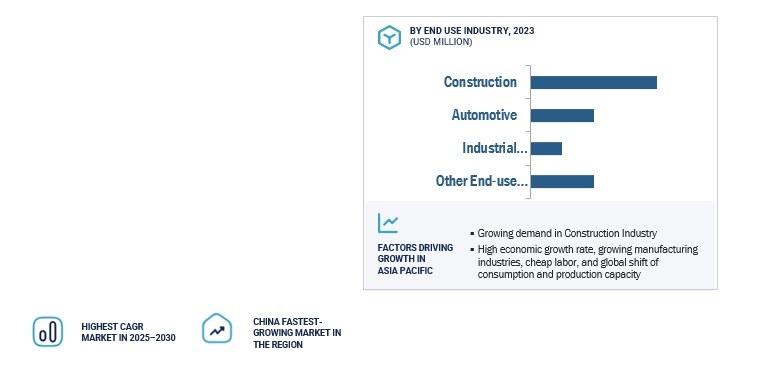

Industrial Manufacturing segment is the fastest growing segment of PVC adhesives market by end use industry in terms of value

The industrial manufacture segment is the most rapidly growing segment in terms of value within the PVC adhesives market segmented by end-use industry. This is primarily due to increasing demand with respect to wide range applications of PVC adhesives in industries like automotive, electronics and machineries. PVC adhesives are very important for bonding PVC components while in those industries because of their durability, waterproof nature and strong adhesion properties. As manufacturing continues to grow worldwide, especially in developing countries, performance and reliability of adhesives for industrial use are generally rising. Thus, the most significant driver of PVC adhesive market growth is industrial manufacturing segment.

North America is the one of the largest markets for PVC adhesive market

North America is one of the largest market for PVC adhesives due to heavy consumption in industries such as construction, automotive, plumbing, and packaging. Such infrastructure coupled with urbanization and industrial activities calls for durable and efficient PVC adhesives. On the other hand, the government regulations enforcing green mandates have also increased the usage of eco-friendly low-VOC adhesives in North America. Moreover, the presence of major manufacturers of adhesives along with strong distribution networks makes this region even more powerful in the PVC adhesives market globally. All of this makes the United States the global industrial giant and the main influencer in the PVC adhesive market: the growth of industry, by the regulations in support, and by innovation.

To know about the assumptions considered for the study, download the pdf brochure

Key Market Players

Henkel AG & Co. KGaA (Germany), 3M Company (US), Sika AG (Switzerland), H.B. Fuller (US), Arkema Bostik (France), Royal Adhesives & Sealants (US), ITW (Illinois Tool Works) (US), Mapei S.p.A. (Italy) are the key players in the global PVC adhesive market.

3M is a manufacturer and distributor of industrial products and solutions. Its portfolio of products includes advanced materials, display materials and systems, home care, home improvement, stationery and office, personal safety, roofing granules, closure and masking systems and others. 3M also offers various solutions such as medical, oral care, consumer health care, food safety, health information systems. It serves customers in various industries such as automotive, electronics, health care, safety, energy and consumer. The company has converting and manufacturing facilities in the Americas, Asia Pacific, Europe, the Middle East and Africa. 3M is headquartered in St. Paul, Minnesota, the US.

Recent Developments in PVC Adhesive Market

- In January 2020, GE Sealants & Adhesives came up with a novel product line of caulks and sealants to offer protection to paints used in outside and inside home renovation, such as bath & kitchens, doors & windows, painting & sealing, etc.

- Bostik is one of the popular specialists in adhesives for industrial, construction, and consumer markets. In September 2019, the company launched innovative and modified silicone sealants for use in back bedding.

To speak to our analyst for a discussion on the above findings, click Speak to Analyst

Frequently Asked Questions (FAQs):

What are the factors driving the growth of the PVC adhesive market?

The growing construction market is driving the market.

What are the major end use industry for PVC adhesive?

The major applications of PVC adhesive are construction and automotive.

Who are the major manufacturers of PVC adhesive?

Henkel AG & Co. KGaA (Germany), 3M Company (US), Sika AG (Switzerland), H.B. Fuller (US), Bostik (France), Royal Adhesives & Sealants (US), ITW (Illinois Tool Works) (US), Mapei S.p.A. (Italy) are the key players in the global PVC adhesive market.

What are the reasons behind PVC adhesive gaining market share?

PVC adhesive are gaining market share due to increasing demand from the Asia Pacific region.

Which is the fastest growing region in the PVC adhesive market?

Asia Pacific is the fastest growing region in the PVC adhesive market.

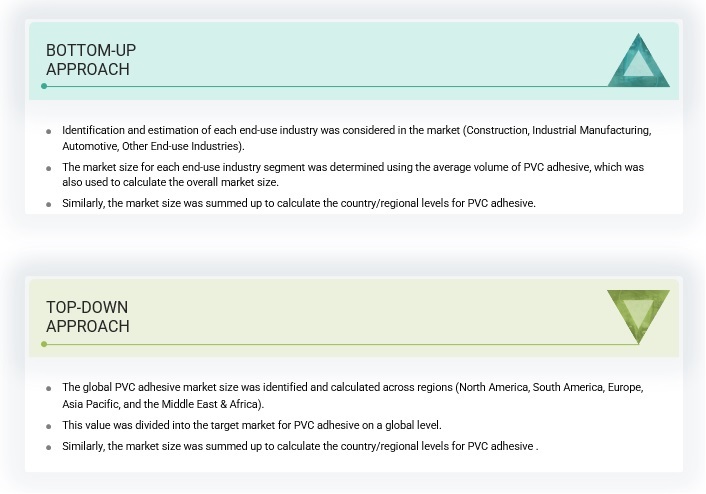

The study involved four major activities in order to estimating the current size of the PVC Adhesive market. Exhaustive secondary research conducted to gather information on the market. The next step was to conduct primary research to validate these findings, assumptions, and sizing with the industry experts across the value chain. Both top-down and bottom-up approaches were used to estimate the total market size. The market size of segments and subsegments was then estimated using market breakdown and data triangulation.

Secondary Research

Secondary sources include annual reports of companies, press releases, investor presentations, white papers, articles by recognized authors, and databases, such as D&B, Bloomberg, and Factiva; and publications and databases from associations, including The Adhesive and Sealant Council (ASC), European Adhesive Manufacturers Group (FEICA), International Adhesive and Sealant Council (IASC), Plastics Industry Association.

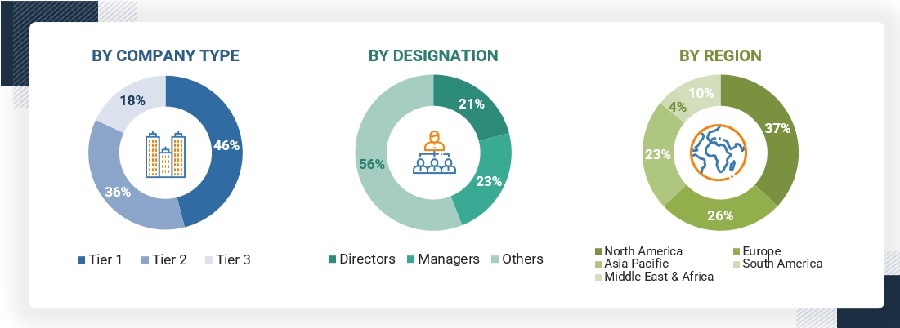

Primary Research

Extensive primary research was carried out after gathering information about PVC Adhesive market through secondary research. In the primary research process, experts from the supply and demand sides have been interviewed to obtain qualitative and quantitative information and validate the data for this report. Questionnaires, emails, and telephonic interviews were used to collect primary data. Primary sources from the supply side include industry experts, such as chief executive officers (CEOs), vice presidents (VPs), marketing directors, technology and innovation directors, and related key executives from various key companies and organizations operating in the PVC Adhesive market. Primary interviews were conducted to elicit information such as market statistics, revenue data collected from the products and services, market breakdowns, market size estimations, market forecasting, and data triangulation. Primary research also assisted in comprehending the various trends associated to type, application, end – use industry, and region.

The breakup of Primary Research:

To know about the assumptions considered for the study, download the pdf brochure

PVC Adhesive MANUFACTURERS

|

PVC Adhesive Manufaturers |

|

|

Henkel AG & Co. KGaA |

Bostik |

|

3M Company |

Mapei S.p.A. |

|

Sika AG |

ITW (Illinois Tool Works) |

|

H.B. Fuller |

Royal Adhesives & Sealants |

PVC Adhesive Market Size Estimation

The following information is part of the research methodology used to estimate the size of the PVC Adhesive market. The market sizing of the PVC Adhesive market was undertaken from the demand side. The market size was estimated based on market size for PVC Adhesive in various technology.

Global PVC Adhesive Market Size: Bottom-Up Approach and Top-Down Approach

To know about the assumptions considered for the study, Request for Free Sample Report

Data Triangulation

After arriving at the overall market size, the market has been split into several segments. To complete the overall market engineering process and arrive at the exact statistics for all segments, the data triangulation and market breakdown procedures have been employed, wherever applicable. The data was triangulated by studying various factors and trends from the demand and supply sides. Along with this, the market size was validated using both the top-down and bottom-up approaches.

Market Definition

The PVC adhesive market is the sector focused on the production and sale of bonding agents specifically designed for use with polyvinyl chloride (PVC) materials. These adhesives are used to create strong, durable bonds in applications like construction, automotive, and industrial manufacturing offering resistance to water, chemicals, and environmental stress.

Key Stakeholder

- End User

- Raw Material Suppliers

- Senior Management

- Procurement Department

Report Objectives:

- To define, describe, segment, and forecast the size of the PVC Adhesive market based on width, type, end – use industry, and region.

- To forecast the market size of segments with respect to various regions, including North America, Europe, Asia Pacific, South America, Middle East & Africa, along with major countries in each region

- To identify and analyze key drivers, restraints, opportunities, and challenges influencing the growth of the PVC Adhesive market

- To analyze technological advancements and product launches in the market

- To strategically analyze micromarkets, with respect to their growth trends, prospects, and their contribution to the market

- To identify financial positions, key products, and key developments of leading companies in the market

- To provide a detailed competitive landscape of the market, along with market share analysis

- To provide a comprehensive analysis of business and corporate strategies adopted by the key players in the market

- To strategically profile key players in the market and comprehensively analyze their core competencies

Available Customizations:

MarketsandMarkets offers the following customizations for this market report:

- Additional country-level analysis of the PVC Adhesive market

- Profiling of additional market players (up to 5)

Product Analysis

- Product matrix, which gives a detailed comparison of the product portfolio of each company in the PVC Adhesive market

Growth opportunities and latent adjacency in PVC Adhesive Market