Multi-Purpose Robots Market by Operating Environment (Ground and Marine), by Component (Hardware and Software) by Application (Material Handling, Cutting & Processing, and Soldering & Welding), by Vertical, and Region – Global Forecast to 2030

Multi-purpose robots can automate several manufacturing applications. It is common for a single robot to be able to perform multiple types of applications such as automated material handling, robotic assembly, robotic machine tending, and automated injection molding applications.

There are various verticals where multi-purpose robots find its applications namely, residential, commercial, and industrial. They are used in various applications such as materials handling, cutting and processing, soldering and welding, and assembling and disassembling applications among others.

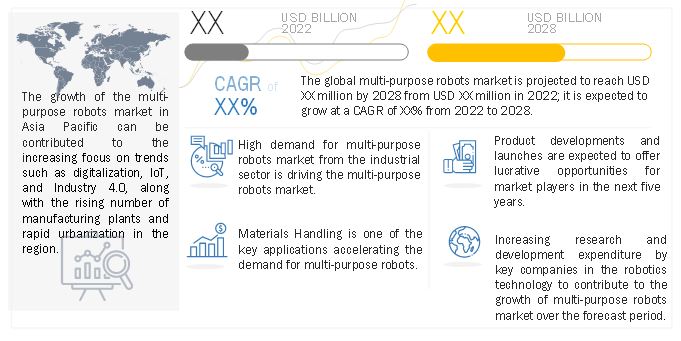

The global multi-purpose robots market size is expected to grow from USD XX million in 2024 to USD XX million by 2030, at a CAGR of XX%. The high adoption of multi-purpose robots in industrial sector is one of the major factors fueling the growth of multi-purpose robots market.

To know about the assumptions considered for the study, Request for Free Sample Report

Drivers: Growing adoption of Industry 4.0

Industry 4.0 refers to the current industrial revolution that is led by the evolution of robotics, automation, and the Internet of Things (IoT). Industry 4.0 and the Internet of Things are increasing the automation of previously manual tasks with a collection of real-time data, AI and device interconnectivity. Industry 4.0 has fostered the development of new technologies such as collaborative robots, and AI-enabled robots, allowing industries to use robots to streamline various processes, boost productivity, and minimize errors. The increasing adoption of industry 4.0 in manufacturing across the globe is among the major drivers leading to the growth of multi-purpose robots in various industries.

Anticipated shortage of skilled labor in manufacturing industries

The anticipated shortage of laborers in developed countries has fueled the need for automation. Manufacturing industries in the US, Germany, and China have experienced tremendous growth over the past decade; however, they are expected to face a workforce shortage within the next few years. The shortage of labor is especially prevalent in jobs with many repetitive and ergonomically unfavorable tasks, such as packaging and monitoring in the food industry. In the US, the growth of the manufacturing sector, coupled with retiring workers and the reluctance of millennials and Generation Z to enter the manufacturing industries, is expected to create a skill gap in the coming years. To compensate for the shortage, stakeholders must find solutions to improve productivity and substitute human labor. Increasing automation to counter the skill gap is one of the solutions companies are adopting, especially in developed countries.

In China, increasing labor costs and a low robot density (robots installed per thousand workers) have threatened productivity, making it difficult for manufacturers to retain their advantage of low manufacturing costs. In response, the Chinese government has introduced the Made in China 2025 initiative, which provides subsidies for the deployment of industrial robots at workplaces. As a result, China topped the shipment of industrial robots purchased in 2021. This factor is fueling the growth of the multi-purpose robots market in the region.

Challenges: Safety concerns related to industrial robotics systems

The initial setup of high-end multi-purpose robots requires a lot of training and expertise. Multi-purpose robots need sophisticated operation, maintenance, and programming. The growing number of people with these skills is still not sufficient to fulfill current demand. As a result, a company must invest in bringing in skilled personnel or retraining its existing staff on the intended application, functionalities, and working of these robots.

Numerous safety issues are associated with multi-purpose robots. Some robots, notably those in a traditional industrial environment, are fast and powerful. This increases the potential for injury as one swing from a robotic arm, for instance, could cause serious bodily harm. There are additional risks when a robot malfunctions or requires maintenance. A malfunctioning robot is typically unpredictable and can cause injury to workers. For instance, a robotic arm that is part of a car assembly line may experience a jammed motor, and the worker fixing the jam may get hit by the arm when it becomes unjammed. Similarly, a worker standing in a zone overlapping with nearby robotic arms may get injured by other moving equipment.

Key Market Players:

ABB (Switzerland), Yaskawa (Japan), FANUC (Japan), Kuka (Germany), Mitsubishi Electric (Japan), Kawasaki Heavy Industries (Japan), and DENSO (Japan) are few key players in the multi-purpose robots market globally.

- In 2021, Fanuc Corporation (Japan) launched FANUC M20ia, a multi-purpose robot capable of automated material handling, robotic assembly, robotic machine tending, and automated injection molding applications.

- In 2021, Avidbots Corporation (Canada) launched the Disinfection Add-On, expanding the functionality of the company’s fully autonomous floor-scrubbing robot, Neo. By simply adding a piece of hardware and pushing a software update, Avidbots’ Neo, the floor-scrubbing robot, now serves multi-purposes.

To speak to our analyst for a discussion on the above findings, click Speak to Analyst

TABLE OF CONTENTS

1 INTRODUCTION

1.1. Objective of the Study

1.2. Market Definition

1.3. Study Scope

1.3.1. Markets Covered

1.3.2. Geographic Scope

1.3.3. Years Considered for the Study

1.4. Currency

1.5. Limitations

1.6. Stakeholders

2 RESEARCH METHODOLOGY

2.1. Research Data

2.1.1. Secondary Data

2.1.2. Primary Data

2.2. Market Size Estimation

2.2.1. Bottom-Up Approach

2.2.2. Top-Down Approach

2.3. Market Breakdown and Data Triangulation

2.4. Assumptions

3 EXECUTIVE SUMMARY

4 PREMIUM INSIGHTS

5 MARKET OVERVIEW

5.1. Introduction

5.2. Market Dynamics

5.2.1. Drivers

5.2.2. Restraints

5.2.3. Opportunities

5.2.4. Challenges

5.3. Trends Impacting Customer’s Business

5.4. Pricing Analysis

5.4.1. Average selling Price of Key Players, By Application

5.4.2. Average selling Price Trend

5.5. Value Chain Analysis

5.6. Ecosystem/Market Map

5.7. Technology Analysis

5.8. Patent Analysis

5.8.1. List of Major Patents

5.9. Case Study Analysis

5.10. Trade Analysis

5.11. Tariffs and Regulatory Landscape

5.11.1. Regulations

5.11.2. Regulatory Bodies, Government Agencies and Other Organizations

5.12. Porter’s Five Forces Analysis

5.13. Key Conferences and Events in 2022-2023

5.14. Key Stakeholders and Buying Criteria

5.14.1. Key Stakeholders and Buying Process

5.14.2. Buying Criteria

6 MULTI-PURPOSE ROBOTS MARKET, BY OPERATING ENVIRONMENT

6.1. Introduction

6.2. Ground

6.3. Marine

7 MULTI-PURPOSE ROBOTS MARKET, BY COMPONENT

7.1. Introduction

7.2. Hardware

7.2.1. Sensors

7.2.2. Actuators

7.2.3. Power Sources

7.2.4. Control Systems/Controllers

7.2.5. Others

7.3. Software

8 MULTI-PURPOSE ROBOTS MARKET, BY VERTICAL

8.1. Introduction

8.2. Residential

8.3. Commercial

8.4. Industrial

9 MULTI-PURPOSE ROBOTS MARKET, BY APPLICATION

9.1. Introduction

9.2. Materials Handling

9.3. Cutting and Processing

9.4. Soldering and Welding

9.5. Assembling and Disassembling

9.6. Others

10 MULTI-PURPOSE ROBOTS MARKET, BY GEOGRAPHY

10.1. Introduction

10.2. North America

10.2.1. US

10.2.2. Canada

10.2.3. Mexico

10.3. Europe

10.3.1. UK

10.3.2. Germany

10.3.3. France

10.3.4. Rest of Europe

10.4. APAC

10.4.1. Japan

10.4.2. China

10.4.3. South Korea

10.4.4. Rest of APAC

10.5. Rest of the World (RoW)

10.5.1. Middle East & Africa

10.5.2. South America

11 COMPETITIVE LANDSCAPE

11.1. Introduction

11.2. Top 5 Company Revenue Analysis

11.3. Market Share/Rank Analysis

11.4. Company Evaluation Quadrant

11.5. Competitive Situation and Trends

11.5.1. Product Launches and Developments

11.5.2. Deals

12 COMPANY PROFILE

12.1. Introduction

12.2. Key Companies

12.2.1. FANUC

12.2.2. ABB

12.2.3. KUKA

12.2.4. Yaskawa Electric Corporation

12.2.5. Avidbots Corporation

12.2.6. Mitsubishi Electric

12.2.7. Adept Technologies

12.2.8. DENSO

12.2.9. EPSON

12.2.10. Hyundai Robotics

Note: This ToC is tentative and minor changes are possible as the study progresses.

Growth opportunities and latent adjacency in Multi-Purpose Robots Market