Metal Injection Molding Market by Material Type (Stainless Steel, Low Alloy Steel, Soft Magnetic Material) End-use Industry (Electrical & Electronics, Automotive, Consumer, Industrial, Medical & Orthodontics, Firearms & Defense) - Global Forecast to 2022

Metal Injection Molding Market Size And Forecast

[130 Pages Report] Metal Injection Molding Market was valued at USD 2.40 Billion in 2016 and is projected to reach USD 3.77 Billion by 2022, at a CAGR of 7.83% during the forecast period. The base year considered for the study is 2016, and the forecast period is from 2017 to 2022.

The objectives of the report are as follows:

- To estimate and forecast the size of the metal injection molding market, in terms of value

- To provide detailed information about the key factors (drivers, restraints, opportunities, and challenges) influencing the growth of the market

- To define, describe, and forecast the metal injection molding market size by material type, end-use industry, and region

- To forecast the size of the market with respect to five main regions (along with key country-level data), namely, Middle East & Africa, North America, South America, Europe, and Asia Pacific

- To strategically analyze micromarkets with respect to individual growth trends, growth prospects, and their contribution to the overall market

- To analyze opportunities in the market for stakeholders and provide a competitive landscape for the market leaders

- To track and analyze competitive developments, such as new product launches, mergers & acquisitions, expansions, and contracts, in the metal injection molding market

- To strategically profile the key market players and comprehensively analyze their core competencies

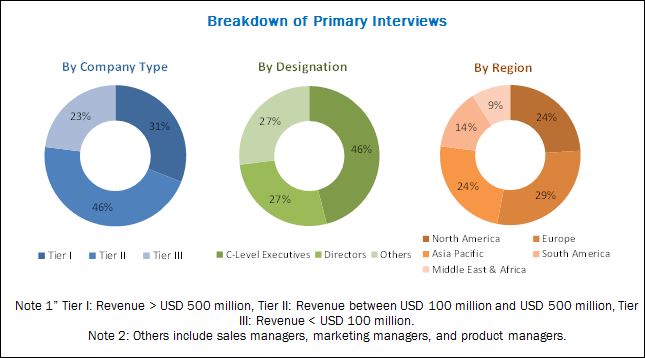

Both, top-down and bottom-up approaches were utilized to estimate and project the size of the metal injection molding market. The size of the metal injection molding market was calculated, and weightages were assigned to various market segments. This was performed on the basis of extensive primary interviews and secondary research based on the information available on websites of various associations, such as Metal Powder Industries Federation, Powder Injection Molding International, and European Powder Metallurgy Association. Primary research included extensive interviews with key personnel, such as CEOs, VPs, directors, and executives of metal injection molding companies. After arriving at the overall market size, the total market was split into several segments and subsegments. The data triangulation and market breakdown procedures were employed to complete the overall market engineering process and arrive at the exact statistics for all segments and subsegments. The breakdown of profiles of primary respondents is depicted in the figure below.

To know about the assumptions considered for the study, download the pdf brochure

Indo-MIM (India), Dynacast International (US), ARC Group Worldwide (US), Phillips-Medisize (US), Smith Metal Products (US), NetShape Technologies (US), Dean Group International (US), Sintex A/S (Denmark), CMG Technologies (UK), Future High-Tech (China), Parmatech Corporation (US), and Parmaco Metal Injection Molding (Switzerland) are the key players operating in the metal injection molding market.

Target Audience:

- Metal Injection Molding Manufacturers

- Metal Injection Molding Distributors

- Metal Injection Molding Suppliers

- Government and Research Organizations

- Raw Material Suppliers

- Associations and Industry Bodies

“The study answers several questions for the stakeholders; primarily, which market segments they need to focus upon during the next two to five years to prioritize their efforts and investments.”

Scope of the Report

The research report categorizes the metal injection molding market into the following segments:

Metal Injection Molding Market By Material Type:

- Stainless Steel

- Low Alloy Steel

- Soft Magnetic Material

- Others (Tool Steel, Titanium, Tungsten)

Metal Injection Molding Market By End-Use Industry

- Electrical & Electronics

- Automotive

- Medical & Orthodontics

- Consumer Products

- Industrial

- Firearms & Defense

- Others (Jewelry, Aerospace)

Metal Injection Molding Market By Region:

- North America

- Europe

- Asia Pacific

- South America

- Middle East & Africa

Available Customizations

Along with the market data, MarketsandMarkets offers customizations according to client-specific needs.

- Further breakdown of the Rest of Asia Pacific, Rest of Europe, Rest of South America, and Rest of Middle East & Africa metal injection molding markets

- Further breakdown of subsegments of the metal injection molding market

- Detailed analysis and profiles of additional market players (up to five)

The metal injection molding market is projected to grow from 2.58 Billion in 2017 to USD 3.77 Billion by 2022, at a CAGR of 7.83% from 2017 to 2022. The growth of this market can be attributed to the increasing demand for small and complex metal injection molded parts from end-use industries, such as electrical & electronics, automotive, medical & orthodontics, industrial, consumer products, and firearms & defense.

The metal injection molding market has been segmented on the basis of material type, end-use industry, and region. On the basis of material type, the market has been segmented into stainless steel, low alloy steel, soft magnetic material, and others (tungsten, tool steel, titanium). The stainless steel segment is estimated to be the fastest-growing material type segment of the metal injection molding market on account of the wide application of stainless steel in various end-use industries. Stainless steel is consumed widely owing to its relatively lower price as compared to other material types. This factor is expected to drive the demand for stainless steel during the forecast period.

On the basis of end-use industry, the metal injection molding market is segmented into electrical & electronics, automotive, industrial, consumer products, medical & orthodontics, and firearms & defense. The electrical & electronics segment is projected to grow at the highest CAGR between 2017 and 2022. This projected high growth is due to the rising demand for miniaturization of electronic devices, which has resulted in the increasing demand for small and complex metal injection molded parts with better performance at a relatively lower cost.

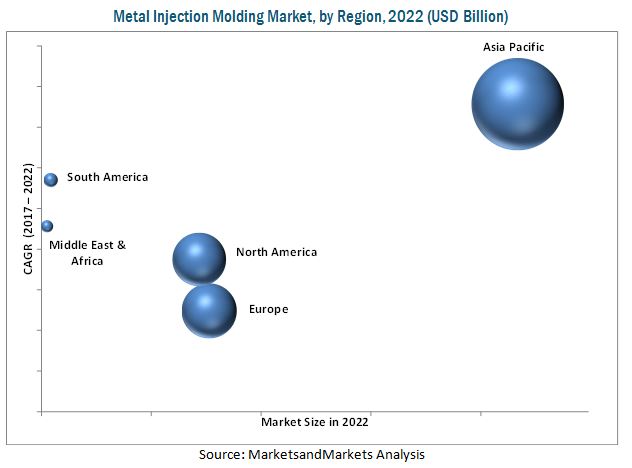

Based on region, the metal injection molding market has been segmented into North America, Europe, Asia Pacific, South America, and the Middle East & Africa. Asia Pacific is estimated to be the largest market for metal injection molding in 2017 and is expected to continue leading the market till 2022. The Asia Pacific metal injection molding market is also projected to be the fastest-growing market between 2017 and 2022. Growing demand from end-use industries, including automotive, electrical & electronics, medical & orthodontics, industrial, firearms & defense, is expected to drive the metal injection molding market in the region. Most of the key players operating in the metal injection molding market have their production facilities in this region since the production cost in this region is lower as compared to other regions.

The growing automotive industry in APAC and rising demand for miniaturization of consumer electronics are increasing the demand for small and complex metal injection molded parts. However, a major factor restraining the growth of the metal injection molding market is the high cost of the metal injection molding process for small production capacities.

New product launches and expansions were the major developmental strategies adopted by key players operating in the metal injection molding market between 2013 and August 2017. Companies such as Indo-MIM (India), Dynacast International (US), ARC Group Worldwide (US), Smith Metal Products (US), and NetShape Technologies (US) adopted these strategies to enhance their product offerings and customer base as well as to gain a competitive edge over their peers in the market. These companies are also focused on investing in research & development activities to introduce new and cost-effective materials to keep up with the changing consumer needs.

To speak to our analyst for a discussion on the above findings, click Speak to Analyst

Table of Contents

1 Introduction (Page No. - 13)

1.1 Objectives of the Study

1.2 Market Definition

1.3 Market Scope

1.3.1 Years Considered for the Study

1.4 Currency

1.5 Limitations

1.6 Stakeholders

2 Research Methodology (Page No. - 16)

2.1 Research Data

2.1.1 Secondary Data

2.1.1.1 Key Data From Secondary Sources

2.1.2 Primary Data

2.1.2.1 Key Data From Primary Sources

2.1.2.2 Breakdown of Primary Interviews

2.2 Market Size Estimation

2.2.1 Bottom-Up Approach

2.2.2 Top-Down Approach

2.3 Data Triangulation

2.4 Assumptions

3 Executive Summary (Page No. - 24)

4 Premium Insights (Page No. - 28)

4.1 Attractive Market Opportunities in Metal Injection Molding

4.2 Market of Metal Injection Molding, By Region

4.3 APAC Market of Metal Injection Molding, By Country and End-Use Industry

4.4 Market of Metal Injection Molding, By Region and End-Use Industry

4.5 Metal Injection Molding Market Attractiveness

5 Market Overview (Page No. - 32)

5.1 Introduction

5.2 Market Dynamics

5.2.1 Drivers

5.2.1.1 Technological Advancements

5.2.1.2 Growing Demand From the Healthcare Industry

5.2.2 Restraints

5.2.2.1 Expensive for Small Production Capacities

5.2.3 Opportunities

5.2.3.1 Newer Applications in Firearms & Defense Industry of North America

5.2.3.2 Growing Automotive Industry in APAC

5.3 Porter’s Five Forces Analysis

5.3.1 Threat of Substitutes

5.3.2 Bargaining Power of Suppliers

5.3.3 Bargaining Power of Buyers

5.3.4 Threat of New Entrants

5.3.5 Intensity of Competitive Rivalry

5.4 Macroeconomic Indicators

5.4.1 GDP Forecast of Major Economies

5.4.2 Trends and Forecast of Automotive

5.4.3 Military & Defense Industry

6 Metal Injection Molding Market, By Material Type (Page No. - 42)

6.1 Introduction

6.2 Metal Injection Molding Process

6.2.1 Mixing

6.2.2 Molding

6.2.3 De-Binding

6.2.4 Sintering

6.3 Stainless Steel

6.4 Low Alloy Steel

6.5 Soft Magnetic Material

6.6 Others

7 Metal Injection Molding Market, By End-Use Industry (Page No. - 53)

7.1 Introduction

7.2 Medical & Orthodontics

7.3 Electrical & Electronics

7.4 Automotive

7.5 Industrial

7.6 Consumer Products

7.7 Firearms & Defense

7.8 Others

8 Metal Injection Molding Market, By Region (Page No. - 63)

8.1 Introduction

8.2 APAC

8.2.1 China

8.2.2 Japan

8.2.3 India

8.2.4 South Korea

8.2.5 Taiwan

8.3 North America

8.3.1 US

8.3.2 Canada

8.3.3 Mexico

8.4 Europe

8.4.1 Germany

8.4.2 France

8.4.3 UK

8.4.4 Italy

8.4.5 Spain

8.5 South America

8.5.1 Brazil

8.5.2 Argentina

8.6 Middle East & Africa

8.6.1 Turkey

8.6.2 Iran

8.6.3 South Africa

9 Competitive Landscape (Page No. - 100)

9.1 Introduction

9.2 Market Ranking of Key Players

9.3 Competitive Scenario

9.3.1 Mergers & Acquisitions

9.3.2 Expansions

9.3.3 New Product Launches

10 Company Profiles (Page No. - 105)

(Business Overview, Products Offered, Recent Developments, SWOT Analysis, MnM View)*

10.1 Indo-Mim Pvt Ltd

10.2 Dynacast International Inc.

10.3 ARC Group Worldwide Inc.

10.4 Phillips-Medisize

10.5 Smith Metal Products

10.6 Netshape Technologies Inc.

10.7 Dean Group International

10.8 Sintex A/S

10.9 CMG Technologies

10.10 Future High-Tech Co. Ltd.

*Details on Business Overview, Products Offered, Recent Developments, SWOT Analysis, MnM View Might Not Be Captured in Case of Unlisted Companies.

10.11 Other Market Players

10.11.1 Parmatech Corporation

10.11.2 Rockleigh Industries

10.11.3 Tanfel Inc.

10.11.4 Ernst Reiner GmbH & Co. Kg

10.11.5 Amphenol Corporation

10.11.6 CN Innovations

10.11.7 Taiwan Powder Technology

10.11.8 Jiangsu Gian Mim Parts

10.11.9 Parmaco Metal Injection Molding AG

10.11.10 Dou Yee Technologies Pte Ltd

11 Appendix (Page No. - 123)

11.1 Insights From Industry Experts

11.2 Discussion Guide

11.3 Knowledge Store: Marketsandmarkets Subscription Portal

11.4 Introducing RT: Real-Time Market Intelligence

11.5 Available Customizations

11.6 Related Reports

11.7 Author Details

List of Tables (87 Tables)

Table 1 GDP Forecast of Key Countries, 2017–2022 (USD Billion)

Table 2 Comparison Between Different Metalworking Technologies

Table 3 Market Size, By Material Type, 2015–2022 (USD Million)

Table 4 Comparison of Different Types of Material

Table 5 Types of Stainless Steel

Table 6 Metal Injection Molding: Stainless Steel Market Size, By Region, 2015–2022 (USD Million)

Table 7 Types of Low Alloy Steel

Table 8 Metal Injection Molding: Low Alloy Steel Market Size, By Region, 2015–2022 (USD Million)

Table 9 Types of Soft Magnetic Material

Table 10 Metal Injection Molding: Soft Magnetic Material Market Size, By Region, 2015–2022 (USD Million)

Table 11 Other Material Types

Table 12 Metal Injection Molding: Other Materials Market Size, By Region, 2015–2022 (USD Million)

Table 13 Market Size, By End-Use Industry, 2015–2022 (USD Million)

Table 14 Use of Metal Injection Molded Parts in Medical & Orthodontics Industry

Table 15 Market Size in Medical & Orthodontics, By Region, 2015–2022 (USD Million)

Table 16 Use of Metal Injection Molded Parts in Electrical & Electronics Industry

Table 17 Market Size in Electrical & Electronics, By Region, 2015–2022 (USD Million)

Table 18 Use of Metal Injection Molded Parts in Automotive Industry

Table 19 Market Size in Automotive, By Region, 2015–2022 (USD Million)

Table 20 Market Size in Industrial, By Region, 2015–2022 (USD Million)

Table 21 Use of Metal Injection Molded Parts in Consumer Products Industry

Table 22 Market Size in Consumer Products, By Region, 2015–2022 (USD Million)

Table 23 Use of Metal Injection Molded Parts in Firearms & Defense Industry

Table 24 Market Size in Firearms & Defense, By Region, 2015–2022 (USD Million)

Table 25 Use of Metal Injection Molded Parts in Aerospace Industry

Table 26 Market Size in Other End-Use Industries, By Region, 2015–2022 (USD Million)

Table 27 Market Size, By Region, 2015–2022 (USD Million)

Table 28 Top 10 Metal Injection Molding Producers in APAC

Table 29 Regulations Related to Metal Injection Molding in APAC

Table 30 APAC: Market Size, By Country, 2015–2022 (USD Million)

Table 31 APAC: Market Size, By Material Type, 2015–2022 (USD Million)

Table 32 APAC: Market Size, By End-Use Industry, 2015–2022 (USD Million)

Table 33 China: Market Size, By Material Type, 2015–2022 (USD Million)

Table 34 China: Market Size, By End-Use Industry, 2015–2022 (USD Million)

Table 35 Japan: Market Size, By Material Type, 2015–2022 (USD Million)

Table 36 Japan: Market Size, By End-Use Industry, 2015–2022 (USD Million)

Table 37 India: Market Size, By Material Type, 2015–2022 (USD Million)

Table 38 India: Market Size, By End-Use Industry, 2015–2022 (USD Million)

Table 39 South Korea: Market Size, By Material Type, 2015–2022 (USD Million)

Table 40 South Korea: Market Size, By End-Use Industry, 2015–2022 (USD Million)

Table 41 Taiwan: Market Size, By Material Type, 2015–2022 (USD Million)

Table 42 Taiwan: Market Size, By End-Use Industry, 2015–2022 (USD Million)

Table 43 Regulations in North America

Table 44 North America: Market Size, By Country, 2015–2022 (USD Million)

Table 45 North America: Market Size, By Material Type, 2015–2022 (USD Million)

Table 46 North America: Market Size, By End-Use Industry, 2015–2022 (USD Million)

Table 47 US: Market Size, By Material Type, 2015–2022 (USD Million)

Table 48 US: Market Size, By End-Use Industry, 2015–2022 (USD Million)

Table 49 Canada: Market Size, By Material Type, 2015–2022 (USD Million)

Table 50 Canada: Market Size, By End-Use Industry, 2015–2022 (USD Million)

Table 51 Mexico: Market Size, By Material Type, 2015–2022 (USD Million)

Table 52 Mexico: Market Size, By End-Use Industry, 2015–2022 (USD Million)

Table 53 Regulations in Europe

Table 54 Europe: Market Size, By Country, 2015–2022 (USD Million)

Table 55 Europe: Market Size, By Material Type, 2015–2022 (USD Million)

Table 56 Europe: Market Size, By End-Use Industry, 2015–2022 (USD Million)

Table 57 Germany: Market Size, By Material Type, 2015–2022 (USD Million)

Table 58 Germany: Market Size, By End-Use Industry, 2015–2022 (USD Million)

Table 59 France: Market Size, By Material Type, 2015–2022 (USD Million)

Table 60 France: Market Size, By End-Use Industry, 2015–2022 (USD Million)

Table 61 UK: Market Size, By Material Type, 2015–2022 (USD Million)

Table 62 UK: Market Size, By End-Use Industry, 2015–2022 (USD Million)

Table 63 Italy: Market Size, By Material Type, 2015–2022 (USD Million)

Table 64 Italy: Market Size, By End-Use Industry, 2015–2022 (USD Million)

Table 65 Spain: Market Size, By Material Type, 2015–2022 (USD Million)

Table 66 Spain: Market Size, By End-Use Industry, 2015–2022 (USD Million)

Table 67 Regulations in South America

Table 68 South America: Market Size, By Country, 2015–2022 (USD Million)

Table 69 South America: Market Size, By Material Type, 2015–2022 (USD Million)

Table 70 South America: Market Size, By End-Use Industry, 2015–2022 (USD Million)

Table 71 Brazil: Market Size, By Material Type, 2015–2022 (USD Million)

Table 72 Brazil: Market Size, By End-Use Industry, 2015–2022 (USD Million)

Table 73 Argentina: Market Size, By Material Type, 2015–2022 (USD Million)

Table 74 Argentina: Market Size, By End-Use Industry, 2015–2022 (USD Million)

Table 75 Middle East & Africa: Market Size, By Country, 2015–2022 (USD Million)

Table 76 Middle East & Africa: Market Size, By Material Type, 2015–2022 (USD Million)

Table 77 Middle East & Africa: Market Size, By End-Use Industry, 2015–2022 (USD Million)

Table 78 Turkey: Market Size, By Material Type, 2015–2022 (USD Million)

Table 79 Turkey: Market Size, By End-Use Industry, 2015–2022 (USD Million)

Table 80 Iran: Market Size, By Material Type, 2015–2022 (USD Million)

Table 81 Iran: Market Size, By End-Use Industry, 2015–2022 (USD Million)

Table 82 South Africa: Market Size, By Material Type, 2015–2022 (USD Million)

Table 83 South Africa: Market Size, By End-Use Industry, 2015–2022 (USD Million)

Table 84 Market Ranking of Metal Injection Molding Manufacturers, 2016

Table 85 Mergers & Acquisitions, 2013–2017

Table 86 Expansions, 2013–2017

Table 87 New Product Launches, 2013–2017

List of Figures (27 Figures)

Figure 1 Metal Injection Molding: Market Segmentation

Figure 2 Metal Injection Molding Market: Research Design

Figure 3 Market Size Estimation: Bottom-Up Approach

Figure 4 Market Size Estimation: Top-Down Approach

Figure 5 Metal Injection Molding Market: Data Triangulation

Figure 6 Stainless Steel to Lead the Market of Metal Injection Molding Between 2017 and 2022

Figure 7 Electrical & Electronics Segment to Register the Highest CAGR Between 2017 and 2022

Figure 8 APAC Accounted for the Largest Market Share in 2016

Figure 9 Increasing Demand From Electrical & Electronics and Automotive End-Use Industries to Drive the Market Between 2017 and 2022

Figure 10 APAC to Dominate the Market of Metal Injection Molding Between 2017 and 2022

Figure 11 China Accounted for the Largest Market Share in 2016

Figure 12 Electrical & Electronics Segment Accounted for the Largest Market Share in APAC in 2016

Figure 13 China to Register the Highest CAGR Between 2017 and 2022

Figure 14 Overview of Factors Governing the Market of Metal Injection Molding

Figure 15 Market of Metal Injection Molding: Porter’s Five Forces Analysis

Figure 16 Global Motor Vehicle Sales, 2016 (Million Unit)

Figure 17 Automotive (Car) Sales Outlook By Country, 2016 (Million Unit)

Figure 18 Military Spending of Key Countries, 2006 Vs.2016 (USD Billion)

Figure 19 Metal Injection Molding Process

Figure 20 Stainless Steel Material Type to Register the Highest CAGR Between 2017 and 2022

Figure 21 Electrical & Electronics Segment to Register the Highest CAGR Between 2017 and 2022

Figure 22 APAC to Register the Highest CAGR During the Forecast Period

Figure 23 APAC Market Snapshot of Metal Injection Molding

Figure 24 North American Market Snapshot of Metal Injection Molding

Figure 25 European Market Snapshot of Metal Injection Molding

Figure 26 Companies Adopted New Product Launches as the Key Growth Strategy Between 2013 and 2017

Figure 27 ARC Group Worldwide Inc.: Company Snapshot

Growth opportunities and latent adjacency in Metal Injection Molding Market