Light Curable Adhesives Market by Resin Type (Silicone, Polyurethane, Acrylic, Epoxy, Others), Substrate(Rubber, Plastic, Metal, Others), Application(Medical, Electronics, Glass Bonding, Industrial Assembly, Others) & Region - Global Forecast to 2029

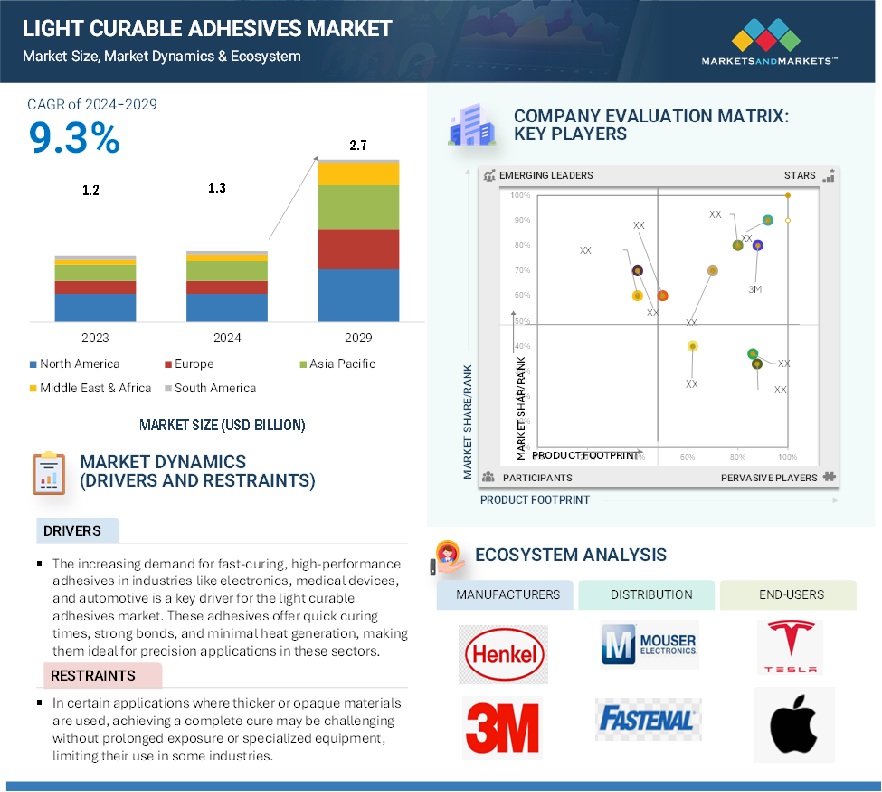

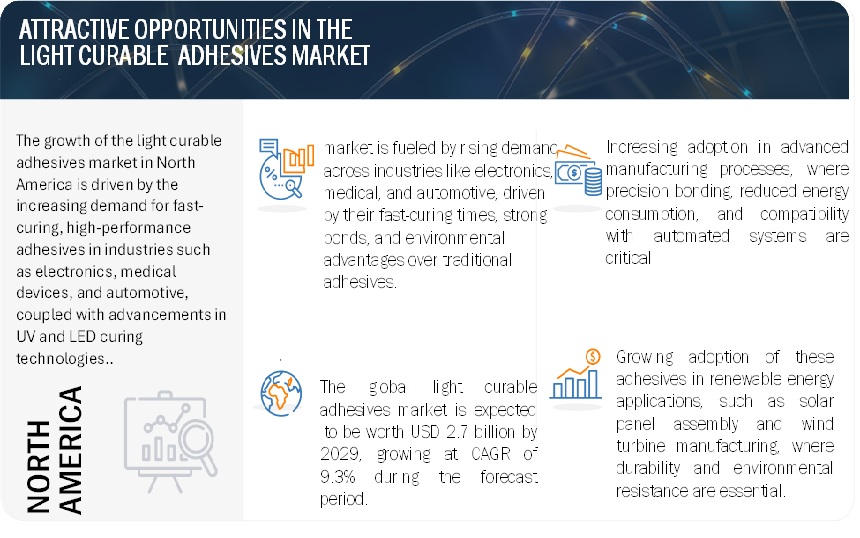

The Light curable adhesives market is projected to reach USD 2.7 billion by 2029, at a CAGR of 9.3% from USD 1.3 billion in 2024 during the forecast period. The market for light curable adhesives is going up significantly because of growth in technology, rising industrial application, and shifting toward the most eco-friendly solutions. In this sense, light curable adhesives like UV and visible light curable adhesives gain wide acceptance as they rapidly cure, exhibit high strength after bonding, and exhibit cross-linking across plastic substrates, glass substrates, metals, and composites substrates. The key end-users are the electronic, automotive, medical equipment, and packaging industries which use these adhesives for applications requiring high precision bonding with minimal waste of adhesives and high productivity. Strong demand for miniaturization of electronic components and sophisticated medical equipment has contributed a lot to the increasing utilization of light curable adhesives as it successfully bonds the most minute pieces. Furthermore, it has an advantage in terms of eco-friendliness as this adhesive emits little to zero VOC. The Asia-Pacific region tops the market because of their expanding electronics and automotive manufacturing business, while North America and Europe are experiencing growth stability with innovation in healthcare and aerospace industries. Challenges include curing equipment costs and opaque substrate limitations, although such ongoing research and development promises to address these issues. Generally speaking, the market will likely continue to grow strongly based on an increase in the usage in emerging industries, plus a further advancement of photochemical curing technologies.

Attractive Opportunities in the Light Curable Adhesives Market

To know about the assumptions considered for the study, Request for Free Sample Report

Light Curable Adhesives Market Dynamics

Driver: increasing demand from medical and electronic industries

The electronics and medical device industries are primarily driving the growth of the light curable adhesives market. These adhesives are valued for rapid curing capabilities, high bond strength, and precision; hence, indispensable for bonding small and intricate components. There has been growing demand in the electronics industries for miniaturized, lighter devices like sensors and printed circuit boards, besides their displays, with adhesives that can cure really quickly without a compromise to the performance. Light curing adhesives meet that requirement by creating strong durable bonds in a few seconds without causing any harm to productivity. Similarly, in medical device industries where precision coupled with biocompatibility prevails, such adhesives are applied in constructing syringes, catheters, and other critical products. Their ability to bond various substrates-including plastics and metals-make them versatile in different applications. Also, the VOC emissions of light curable adhesives are kept low in accordance with light curable adhesives' strict regulatory requirements across these industries. As healthcare advances and technology speeds up the pace, the demand for the light curable adhesives will be sustained. The distinctive properties of these materials, along with their ability to meet the emerging needs of these high-growth industries, make them an important part of modern manufacturing.

Restraints: limited effectiveness on opaque surfaces

A major drawback of light curable adhesives is their dependence on direct exposure to specific wavelengths of light for curing. Such dependence creates problems in bonding opaque substrates or where the penetration of light is restricted. For example, when the materials are multilayered or thick, light may not penetrate the deeper adhesive layers, which will be incompletely cured and may result in weak bonding. This limits the applicability of light curable adhesives in heavy equipment manufacturing, construction, or any business where metals and composites are the major material to be used. Other types of industries also find a problem with the concealed nature of adhesive application areas and difficult access of these areas. In an effort to counter such limitations, manufacturers may employ dual-cure systems or alternative adhesive technologies, which, however tend to increase cost and complexity. Although research is ongoing for advanced photoinitiators and dual-cure adhesives to overcome this limitation, the current situation still leaves a dependency on exposure to light as the most limiting factor for greater usage. Companies have to balance the benefits of fast curing and strong bond strength against the practical constraints posed by material and application constraints, which can also affect the growth of the market in certain segments.

Opportunity: Eco-friendly and VOC free solutions

The increasing importance of the environment and compliance with legislations offers a great prospect for light curable adhesives. Since the emphasis on VOC reduction has forced industries to opt for eco-friendly alternatives, light curable adhesives are becoming an ideal solution. They essentially have minimal or no VOC emissions during application and cure. Further, the energy-efficient curing process helps reduce the carbon footprint, making them very appealing for eco-conscious manufacturers. Industries like automotive, electronics, and packaging are most attracted by these adhesives since they bring along environmental benefits and high performance along with precision. In addition to the requirements of regulations, companies embracing light curable adhesives can support their corporate sustainability initiatives to increase market appeal and competitiveness. Increasing consumer demand for environmental-friendly products pushes the usage of these adhesives in end-use industries. Further innovations in photoinitiators and resin chemistries will extend the applicability of VOC-free solutions and open up new avenues for growth in emerging markets. Capturing these green advantages can take the light curable adhesives market through some phenomenal growth while aiding in the overall transition to a sustainable manufacturing process for the world.

Challenge: High initial cost of curing equipment

One of the major difficulties for the market of light curable adhesives is the cost of the curing equipment. While UV or LED curing systems have to be used to trigger the adhesive curing process, this is prohibitively expensive for SMEs. Added to the original purchase cost are maintenance and replacement costs for light sources and the energy consumed. These factors may discourage potential adopters, especially in price-sensitive regions where capital investment in advanced equipment is a significant hurdle. In addition, the costs can slow down the adoption of light curable adhesives in emerging industries or smaller-scale operations where alternatives such as thermal or moisture-curing adhesives may be considered more economically viable. The high initial investment is a major challenge for many businesses because long-term operational benefits, such as curing times reduced and productivity increased, offset the high costs. This challenge would be overcome through innovation in design and manufacturing of curing equipment, thereby making it affordable and accessible. Educational initiatives on cost efficiency over time may be a way to drive the adoption of light curable adhesives in cost-conscious sectors.

Light Curable Adhesives Market Ecosystem

The market ecosystem of light curable adhesives represents a dynamic network that connects raw material suppliers, manufacturers of the adhesives, providers of equipment, distributors, and end-use industries. Raw material suppliers supply such critical inputs as photoinitiators and resins. Adhesive manufacturers develop products that can cater to different applications. Providers of equipment help out by providing UV and LED curing systems necessary to activate the adhesive. Distributors help bridge that gap between the manufacturers and the end-users in markets including electronics, medical devices, automobiles, and packaging among others. The business thrives upon technological advancements, regulatory compliance, and sustainability trends with innovation and collaboration among stakeholders to meet industry demands across diverse industries.

Source: Secondary Research, Interviews with Experts, and MarketsandMarkets Analysis

Based on resin type, acrylic is the leading segment for Light curable adhesives market.”

Acrylic resins are anticipated to occupy the largest share of light curable adhesives due to versatility, fast cure time, and applicability to almost all types of industry. Acrylic-based adhesives exhibit superior strength, durability, and are compatible with several substrates that include metals, plastics, glass, and composites. Thus, they find critical use in electronics, medical applications, and automobile industries. Their superior resistance to environmental factors such as UV light, moisture, and temperature variation makes them more desirable in outdoor and industrial applications. Besides, acrylic resins are known to cure very quickly under UV or visible light, which makes the high-speed manufacturing environment much easier with regards to production. Epoxy and polyurethane resins provide better chemical resistance and mechanical properties, but curing is relatively slower than in acrylics. Cyanoacrylates are mainly used for niche applications due to the instant bonding ability and, therefore, are not as widespread as acrylics. Silicone-based adhesives are known for superior flexibility and thermal stability; however, these are most often used for special applications than general bonding. Advances in the photoinitiators and the formulation also give acrylic resins the capability to serve in a variety of emergent applications. This speed, strength, and adaptability position acrylic resins as the number one choice in the market of light curable adhesives.

“Based on substrate, plastic is the leading segment for the Light curable adhesives market in 2023.”

Plastics are the most demanding and biggest portion of the light curable adhesives market owing to widespread usage in various applications that pose specific bonding challenges to a material. The demand in plastic usage in electronics, automobile, medical devices, and packaging industries has made demand for high-performance adhesives that can achieve excellent bonding with different kinds of plastic substrates. The most significant advantage of light curable adhesives in plastics is their fast curing, high bond strength, and low shrinkage. These ensure precise and reliable bonding of intricate components. Miniaturized plastic components in sensors, displays, and circuit boards are becoming more and more prevalent in the electronics industry, where fast curing without heat generation is necessary, a property in which light curable adhesives excel.

In addition, plastics are used in the automobile sector for lightweighting and efficiency in energy consumption; in these sectors, adhesives need to provide strong bonds withstanding dynamic stress and environmental exposure. Medical devices also enhance demand for adhesives applied in plastic assemblies used for catheters, syringes, and other diagnostic equipment, where the criteria include biocompatibility and precision. While metals, glass, and rubber are important segments, their applications are often rather more specialized. Plastics dominate since they are the most prominent material in manufacturing and because lightweight, cost-effective materials are in ever-growing demand in contemporary product design.

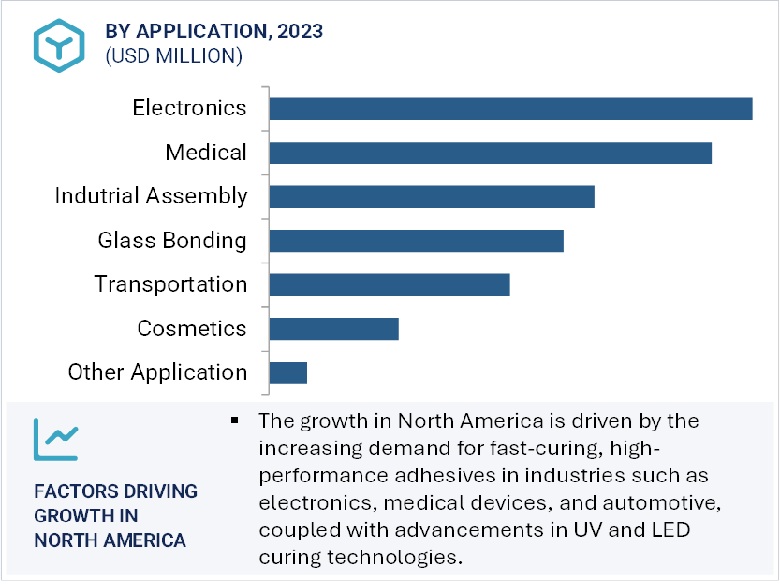

“Based on application, electronic segment would be the largest subsegment for Light curable adhesives market in 2023”

The electronics sector is expected to be the largest application segment in the light curable adhesives market, driven by the fast growth of electronic devices and components around the world. Light curable adhesives are widely used in this industry for their ability to bond intricate and delicate parts, fast curing times, and excellent performance on diverse substrates such as plastics, glass, and metals. The increasing demand for miniaturized, lightweight, and high-performance electronic devices, such as smartphones, wearables, sensors, and printed circuit boards (PCBs), drives the need for precise and efficient adhesive solutions. They apply in electronic manufacturing in applications involving potting, encapsulation, conformal coatings, and even assembling components like displays, connectors, and microchips. Their superior thermal stability and electrical insulation properties and high resistance to environmental factors contribute to their inevitability in high-reliability applications. Also, consumer electronics, automotive electronics, and 5G infrastructure expand further, with demand from the advanced adhesives tailored to such applications continuing its upward trend. While medical and transportation areas are also substantial contributors, adoption there is often niche-oriented. The electronics industry leads because it is the largest in scale, with constant innovation, and because it relies heavily on precision assembly processes that most directly benefit from the unique properties of light curable adhesives.

“Based on region, North America was the largest market for Light curable adhesives in 2023.”

North America is the largest shareholder in the light curable adhesives market as it has an advanced industrial base, strong end-use industries, and a focus on technological innovation. The electronics, medical devices, and automotive sectors in the region are well-developed and demand-intensive. The United States leads the world in electronics and medical device manufacturing, where precision bonding and rapid curing are critical. The light curable adhesives have the potential to increase production efficiency in those high-growth industries. Furthermore, the stricter environmental regulations in North America have hastened the use of eco-friendly and VOC-free adhesive solutions that light curable adhesives excel in. The need for sustainability and green manufacturing in the region also augurs well for them. Investment in research and development and the presence of prominent adhesive manufacturers and technology providers guarantee continuous innovation and acceptance of state-of-the-art adhesive technologies. The region also benefits from growing demand for lightweight materials in the automotive industry in electric vehicles, in which light curable adhesives are used in bonding and sealing applications. In combination with increasing adoption in industrial assemblies and packaging, North America's well-developed infrastructure, regulatory support, and strong industrial presence firmly position it at the top in the global light curable adhesives market.

To know about the assumptions considered for the study, download the pdf brochure

Key Market Players

- 3M (US)

- H.B. Fuller Company (US)

- Henkel AG & CO. KGAA (Germany)

- Dymax (US)

- Permabond Engineering Adhesives (US)

- Dow (US)

- EPOXY TECHNOLOGY, INC (US)

- Loxeal S.r.l (Italy)

- Delo Industrial Adhesives (Germany)

- Ashland (US)

Recent Developments in Light Curable Adhesives Market

- In July 2024, Henkel announced the completion of Phase III of its manufacturing facility in Kurkumbh, Maharashtra, india. This expansion aims to meet the growing demand for high-performance adhesive solutions in India, particularly for automotive and industrial applications. The new Loctite plant will enhance local production capabilities and reduce reliance on imports.

- In June 2024, Dymax partnered with Ingenieria en Sistemas de Adhesivos (ISASA) to strengthen its presence in Mexico. This collaboration enables ISASA to promote and support Dymax's innovative light-curable solutions across the general industrial market.

- In July 2022, Arkema, a leading chemical manufacturing company based in France, acquired Permoseal Ltd., a South African chemical company specializing in UV light-curable glues and adhesives, for an undisclosed amount. This strategic acquisition aims to bolster Arkema's presence in the South African adhesives market while expanding its portfolio of advanced adhesive solutions across various industries and applications.

To speak to our analyst for a discussion on the above findings, click Speak to Analyst

Frequently Asked Questions (FAQ):

What are the factors influencing the growth of the light curable adhesives market?

Market growth for light curable adhesives is mainly contributed by the increasing demand in end-use industries, especially from electronics, medical devices, automotive, and packaging. The performance of UV and LED curing systems enhances because of technological advancements; such performance allows for faster curing and excellent bond strength. Sustainability targets are met with light curable adhesives through the reduction of VOC emissions while meeting stringent environmental regulations. Their adoption also benefits from cost efficiency; they consume less energy, and their production cycles are faster. The growth in the electronics manufacturing industry, especially in emerging markets, and innovations in specialized formulations of adhesives supports market growth.

Define Light curable adhesives market?

Light curable adhesives are adhesives that cure or harden in response to ultraviolet (UV) or visible light. They usually work with UV or LED lamps. They are formulated with photoinitiators that initiate polymerization when exposed to light, providing fast curing, precise bonding, and little heat generation. Light curable adhesives are very much in use in various applications including electronics, medical device industries, automotive, and construction industries, where its ability to provide a broad spectrum of substrates along with plastics, metals, and glass, it serves the purpose of a great strong and durable bond and low VOC emissions makes eco-friendly.

Which region is expected to have the largest market share in the Light curable adhesives market?

The North America region will acquire the largest share of the Light curable adhesives market during the forecast period.

What are the major market players covered in the report?

The key players in this market are 3M (US), H.B. Fuller Company (US), Henkel AG & CO. KGAA (Germany), Dymax (US), Permabond Engineering Adhesives (US), Dow (US), EPOXY TECHNOLOGY, INC (US), Loxeal S.r.l (Italy), Delo Industrial Adhesives (Germany), Ashland (US).

How big is the global Light curable adhesives market?

The Light curable adhesives market is projected to reach USD 2.7 billion by 2029, at a CAGR of 9.3% from USD 1.3 billion in 2024 during the forecast period.

Light Curable Adhesives Market

Growth opportunities and latent adjacency in Light Curable Adhesives Market