Future of Manufacturing Market by Digital Factory, Micro Factory, Giga Factory, Technology (Cloud Manufacturing, Edge Computing, Digital Twin, AR/VR, 5G/6G), Design (Modular, Mobile, Integrated and Sustainable Factory), Cybersecurity - Global Forecast to 2030

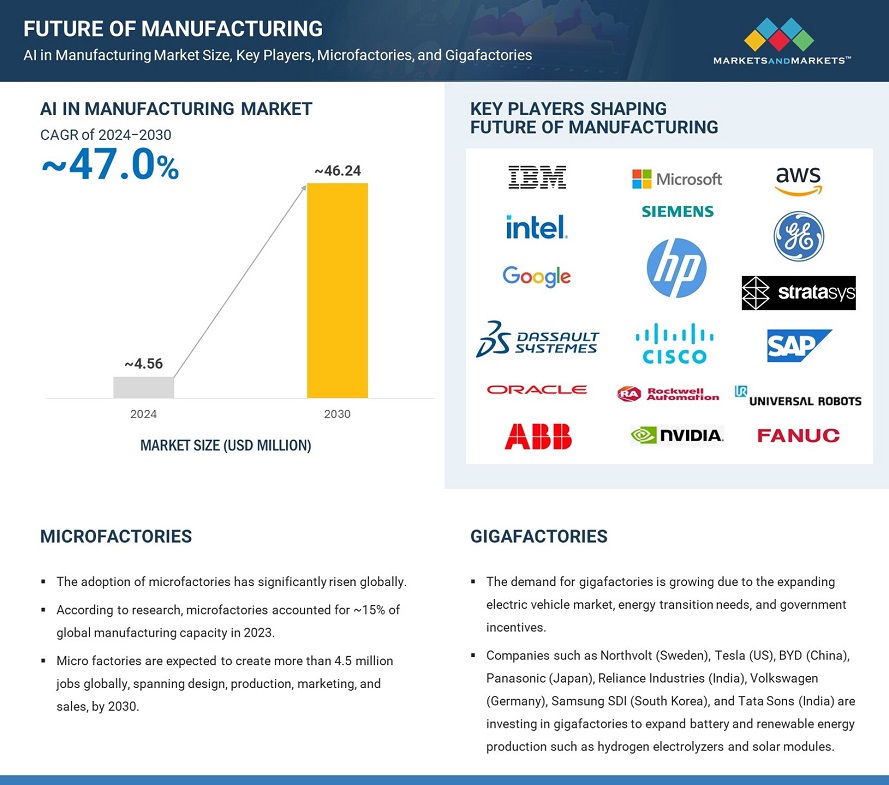

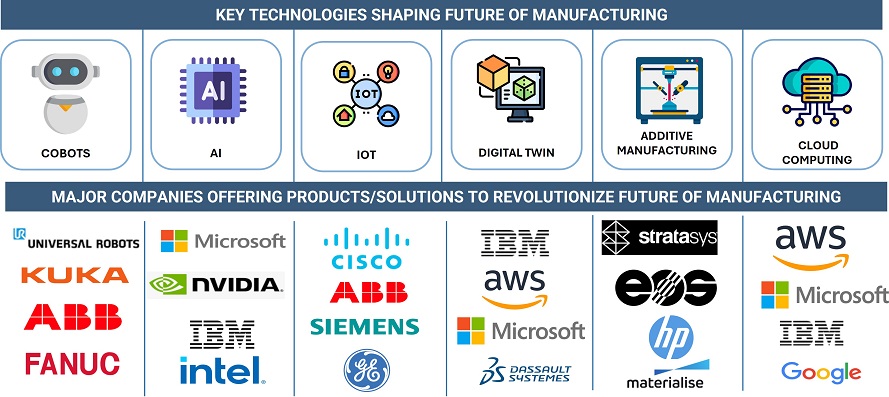

The future of manufacturing market will be led by AI, digital twins, and collaborative robots. The AI in manufacturing market is projected to reach ~USD 46 billion by 2030, growing at a CAGR of 47%, while the digital twin market is expected to hit ~USD 150 billion, at a CAGR of ~60%. The collaborative robot market is predicted to reach ~USD 12 billion at a CAGR of ~35% during 2025–2030.

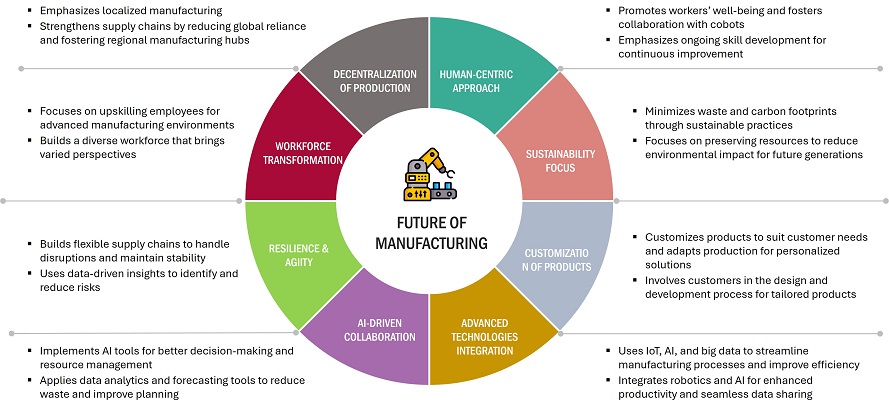

The future of manufacturing industry is rapidly evolving with a focus on a human-centric approach, integrating AI, robotics, and automation to boost productivity while prioritizing workers’ well-being. Sustainability is crucial, with factories adopting renewable energy, zero-waste practices, and eco-friendly materials. Customization is transforming production by utilizing flexible systems that enable mass personalization.

Looking beyond 2030, manufacturing will become more adaptive with AI-driven communications between machines and workers, deep sustainability practices, and decentralized manufacturing hubs for quicker responses. Continuous workforce reskilling will be essential to managing advanced technologies. Business owners will develop a micro factory and a gigafactory to meet diverse manufacturing demands over the next 5–10 years while redefining job roles and collaborating with educational institutions for tailored training.

Key Drivers Shaping Future of Manufacturing Market

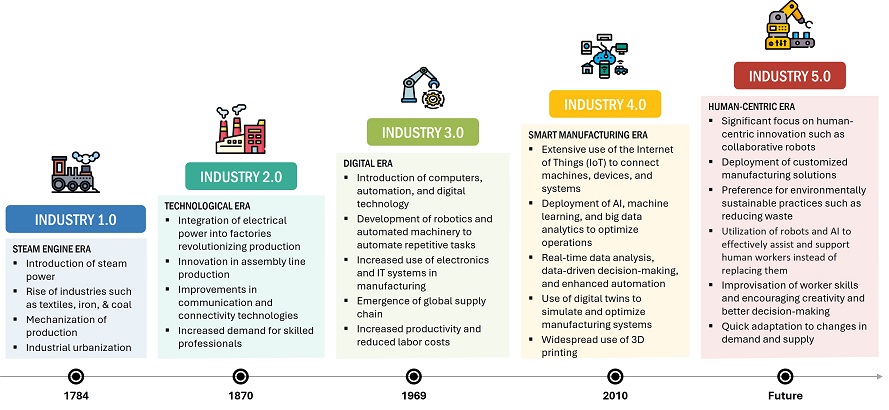

Progressive Transformation of Industrial Processes Through Technological Innovation: Industry 1.0 to 5.0

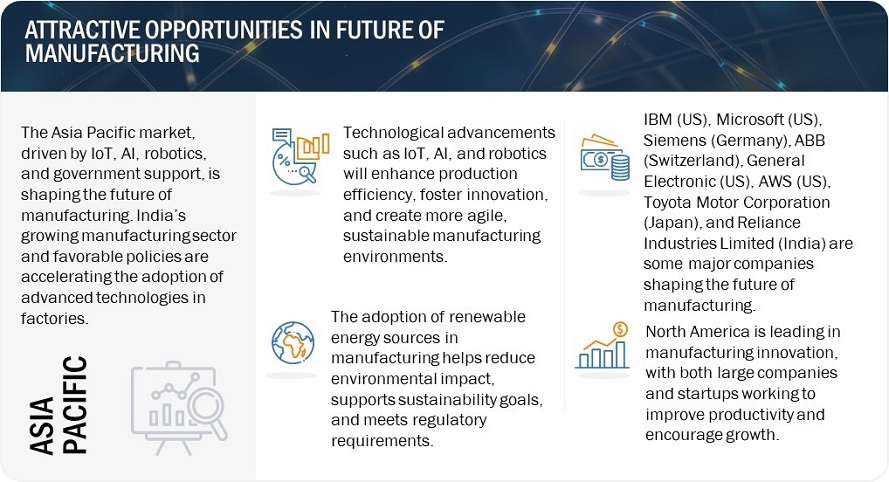

Attractive Opportunities in Future of Manufacturing Market

Rising Focus on Implementing More Sustainable Manufacturing Practices

The future of manufacturing market will witness drastic changes, focusing on sustainability through technological advancements and reducing environmental impact. In 2030 and beyond, factories will be transformed into efficient systems that utilize energy effectively while minimizing waste. Automation and AI will play a crucial role in optimizing production lines, minimizing resource consumption, and reducing emissions. Digital twins and IoT will enable real-time monitoring and predictive maintenance, ensuring that machinery operates at peak efficiency. Moreover, the circular economy shall emerge; factories will design products to recycle materials, use components, or design for disassembly to minimize waste. Adopting sustainable practices will help combat climate change, improve functionality, reduce prices, and adhere to specific consumer requirements. As a result, factories will evolve into resilient, resource-efficient ecosystems that contribute to both economic growth and environmental sustainability, shaping the future of manufacturing market.

Shaping Future of Manufacturing Operations with Flexible and Efficient Collaborative Robots

Collaborative robots, also known as cobots, are revolutionizing the future of manufacturing as they enhance human and robot cooperation, leading to increased output and addressing the issue of human labor scarcity. Because of their small size, relatively low weight, and minimal programming needs for complex operations, they are easily adaptable and relatively inexpensive for a number of fields, such as automotive, electronics, and pharmaceuticals. Cobots function well in material assembly, quality inspection, welding, and packaging while outperforming flexible robots. For instance, Nissan installs UR10 cobots to change the orientations of engine models, while Comprehensive Logistics improves the quality of its engines by using cobots to check and evaluate them. Cobots are transforming the factories into more amorphous and effective production facilities for advanced manufacturing and industrial development by improving performance, maintaining accuracy, and minimizing downtime.

Enhancing Manufacturing Efficiency and Resilience Through Adoption of AI

AI is rapidly becoming a popular and standard aspect that enhances production efficiency without much human interference. According to the analysis, ~39% of manufacturers today are already using AI, and the leading players are machinery and aircraft component manufacturers. Big investments from several firms, such as Cisco, which has pledged USD 1 billion; Microsoft, which has USD 3.3 billion; and partnerships, such as NVIDIA–Foxconn, are transforming the manufacturing landscape. They are using complex AI-based solutions that can improve production performance and product quality. They also focus on predictive maintenance. All such strategies and moves have improved current manufacturing processes and facilitated the development of dynamic and sustainable factories.

Transforming Future of Manufacturing Market by Adopting Decentralized Manufacturing Technique

As technology progresses and the roles of digital services in organizations grow, companies adopt flexible strategies and decentralize their operations to stay competitive. There is increased adoption of decentralized operations where production exercises are not limited to one plant or factory. This method is more adaptable, scalable, and reliable due to the capability of designing in parallel at one site while assembling and testing at another. A key feature of decentralized manufacturing is on-demand production, where goods are made only when needed, making it ideal for small batches or prototyping, with room to scale up. Production sites are connected through traditional methods or modern technologies, including the Internet of Things (IoT), improving communication and coordination. This model also strengthens supply chains by reducing reliance on a single location, making the supply more stable and reliable. Advanced technologies, such as digital twins, CAD software, 3D printing, robotics, and automation, are central to this process. The collaboration between procurers, makers, and consumers enables businesses to meet market demands promptly. Thus, decentralized manufacturing plays an important role in determining the future of manufacturing market.

Unlocking New Possibilities and Enhancing Future of Manufacturing Market Through 5G and 6G

The manufacturing industry nowadays depends heavily on advanced technologies such as robots, IoT devices, and digital twins, and all these are made possible by 5G. Research indicates that it helps address labor shortages, with more than ~2 million workers required by 2030. In the future, 6G is expected to advance this even further. The next generation 6G is predicted to emerge around 2030, achieving speeds 100 times faster, with a potential capacity of 1 terabit per second. This will create opportunities for industries. Manufacturing organizations and other industrial organizations, including Apple, Qualcomm, and Nokia, are already looking at 6G to develop better connectivity and newer solutions that will take manufacturing to the next level.

Revolutionizing Factory Production for Faster and More Efficient Future with Deployment of Additive Manufacturing

3D printing or additive manufacturing rapidly reshapes manufacturing through effective, efficient, and inexpensive processes. The aerospace, healthcare, and automobile sectors are pioneers, with prominent players such as GE Aerospace and Bentley Motors investing in 3D printing to enhance efficiency and ensure production reliability in their manufacturing sites while setting new standards for quality and performance. By 2030, most commercial and industrial 3D printers will feature integrated AI, enabling them to detect maintenance issues and adjust prints for specific requirements autonomously. In addition, small-scale 3D printing services will emerge and provide various solutions to consumers. These are some of the advances in additive manufacturing, which will revolutionize manufacturing and create opportunities for smart factories.

Rise of Microfactories Unlocking Opportunities for Localized Production and Speedy Product Development

Microfactories are currently being adopted as a strategic innovation that defines factories. These define small-scale and medium-scale production modes that apply smart technologies, including AI, automation, and machine learning, which are proven more efficient, cost-saving, and flexible than typical production methods. Such ideas are already in practice today; for instance, Arrival has tiny micro-factories where electric vehicles are assembled and GE Appliances constantly uses small-batch production to test certain appliances and quickly bring them to the market. Microfactories accounted for nearly 15% of global manufacturing capacity in 2023 and are expected to create 4.5 million jobs globally, spanning design, production, marketing, and sales by 2030. Micro-factories address the inefficiencies of traditional manufacturing by enabling localized production, reducing costs, and speeding up product development. This not only revolutionizes the current manufacturing industry but also stimulates economic development and transforms the global manufacturing system.

Emergence of Gigafactories to Ensure Sustainable Manufacturing

Gigafactories are revolutionizing the architecture of factories in the EV ecosystem and clean energy technology industries such as solar manufacturing and hydrogen fuel cell manufacturing. These mass-scale hi-tech plants are crucial to address the rising need for clean electricity and increase output in generating renewable power while lowering prices. Tesla, Northvolt, Reliance Industries, and Tata Sons are demonstrating the way how multi-billion gigafactories could be built to produce EV batteries, renewable energy storage solutions, and green hydrogen. For instance, Reliance Industries Limited (India) announced a commitment of over USD 10 billion to establish over 4 gigafactories in India, focusing on renewable energy, battery storage, hydrogen, and fuel cells. Backed by government initiatives and corporate funding, gigafactories are set to drive energy shifts, boost energy security, and contribute to net-zero emission goals. Gigafactories are becoming vital for India, China, and Europe as they help transform industries and shape the future of manufacturing Market by enabling high-volume and low-cost production of sustainable energy.

Future of Manufacturing Market in North America

North America is undergoing significant transformation to maintain its status as a leading manufacturing hub. The US, Canada, and Mexico are at the forefront of innovative technologies, including artificial intelligence and digital twin, and sustainability initiatives. The US government will invest up to USD 100 million to accelerate AI-driven research and development for sustainable semiconductor materials and would invest USD 285 million to advance digital twin technology in semiconductor manufacturing, enhancing efficiency and supply chain resilience.. Canada will invest USD 427 million to support a project aimed at enhancing innovation and generating 50,000 jobs by 2028. Various federal laws, such as the Infrastructure Investment and Jobs Act, the Inflation Reduction Act, and the CHIPS and Science Act, are now aiding the region to regain manufacturing by bringing back jobs at home, diversifying its supply chains and the green energy field. Mexico’s positioning and investments in automotive and electric vehicles are also contributing to manufacturing growth.

India's Strategic Investments Will Boost Smart Manufacturing Practices by 2030

India is making significant investments in various fields, such as semiconductors, renewable energy, defense, and data centers, making the country a world leader by 2030. For instance, in the semiconductor industry, Tata Electronics (India) and Taiwan’s Powerchip Semiconductor Manufacturing Corp. (PSMC) (Taiwan) are planning to invest USD 11 billion to set up fabrication plants in the country. In addition, the defense sector is also witnessing growth due to initiatives such as Aatmanirbhar Bharat which aims for greater self-reliance. Furthermore, the digital infrastructure is being powered by some of the data center investments that are building India. For instance, Adani Group has announced a USD 6 billion investment in data center infrastructure in India. Furthermore, the country is investing highly in other sectors, such as logistics, pharmaceuticals, and aviation, to boost the country's economy and become a global leader. In the next decade, India will become an innovative, sustainable, strong economic power, and a global perspective.

Recent Investments Will Drive Growth Across Various Industries in India

The "MarketsandMarkets – Future of Manufacturing Market” report is designed to be a vital tool for consumers and market leaders searching for their way through a rapidly changing manufacturing landscape. This report is based on years of experience in this rapidly changing manufacturing sector; it incorporates insights from experts in the industry and includes thorough evaluations conducted by analysts. The report offers an all-rounded view of the trends, opportunities, and challenges shaping the future of manufacturing Market through a wide-ranging interview process with stakeholders worldwide. It is to prepare businesses with the necessary information to help them respond to the dynamic nature of the environment.

The Future of Factories Market is poised to provide comprehensive projections on the factory landscape and highlight the key trends shaping the production environments. The report covered the key driving areas shaping the future of factories, such as Automation and Robotics, Smart Manufacturing, Sustainable Practices, Digital Transformation, and AI and IoT integration into manufacturing. It provides a summary of the current status of the manufacturing industry while offering emerging trends that are driving market dynamics.

Furthermore, it involves the development of Industry 4.0 technologies such as 3D printing and IoT; and moving focus toward sustainability, apart from increasing emphasis on data-driven decisions for operations within the manufacturing industry. The study details how firms rely on smart technologies to drive efficiency and cost savings and react to dynamic changes in consumers' preferences. Furthermore, the report emphasizes the significance of embracing digital tools and platforms to maintain competitive advantage in a rapidly changing landscape.

By drawing insights from historical performance and forecasting the anticipated impact of these trends, the report will generate predictions for the future of factories Market.

The objectives of the report on the Future of Factories Market - Forecast to 2030 are mentioned as follows:

- To understand the performance of the factories in 2023

- To analyze the top developments and disruptions that took place in 2023

- To understand the key trends that are likely to impact the industry in the future

- To estimate the performance of the industry at the global level as well as for each of the key regions considered in the report and by sectors/segments

- To identify growth opportunities and provide recommendations for market participants to tap opportunities

- To understand the current state of the factories and to gain insights into the shifting consumer preferences within the market

The report will encompass statistical data and prognostications regarding factory performance. This comprehensive analysis will extend to various growing markets, encompassing overall figures, regional variations, and specific insights into key countries. The major markets discussed in the study are key trends shaping the future of factories, advanced technologies, future factory design, the global landscape of factories, and more.

The report describes significant trends that are predicted to shape the future of factories maket as follows:

- Advanced Technologies Integration: AI, machine learning, and IoT for increased efficiency in automation, predictive maintenance, and real-time data analytics during production.

- Sustainable Manufacturing: Increase focus on sustainability through reduced waste, energy efficiency, and use of eco-friendly materials.

- Mass Customization: The trend toward mass customization in order to fulfill specific requirements and preferences of the customer.

- Supply Chain Resilience: Concentration on developing responsive supply chains in order to better adapt to the disruptions across the world so that the product can be available on time.

- Workforce Change: Change in the workforce through upskilling and collaborative robots for enhanced human-robot collaboration.

By analyzing these trends and drawing insights from historical performance, the report will formulate forecasts for the future of factories market, providing a comprehensive outlook on its future trajectory.

Research Methodology

The research methodology involves three key components: (a) secondary research, incorporating historical data from MarketsandMarkets (MnM) reports and Knowledge Store, market data gathered from various associations, industry bodies, and third-party databases across regions, and the extraction of key trends, market drivers, and restraints from various industry articles, reports, and journals; (b) Expert Opinions, entailing interviews with key experts to collect insights on key trends, their impact, market drivers and restraints, and industry performance; and (c) MarketsandMarkets (MnM) Analysis. MnM consultants and analysts, with a combined experience exceeding 100 years, continually monitor the industry, regions, sectors, and players. This ongoing surveillance and existing market knowledge form the basis for analysis and market forecasting.

Who should be interested in the report?

The report holds significance for industry stakeholders, including manufacturers, production managers, technology providers, industry analysts, suppliers, distributors, and others engaged in the manufacturing industry. It provides valuable insights for leadership and teams involved in strategy, product development, research and development (R&D), sales, and marketing, as well as those focusing on new market development.

Growth opportunities and latent adjacency in Future of Manufacturing Market