Friction Bonding Adhesive Market by Type (Epoxy Based Adhesive, Polyurethane Adhesive, Other Types), End use Industry (Automotive, Aerospace, Industrial, Other End-use Industries), and Region (2025-2030)

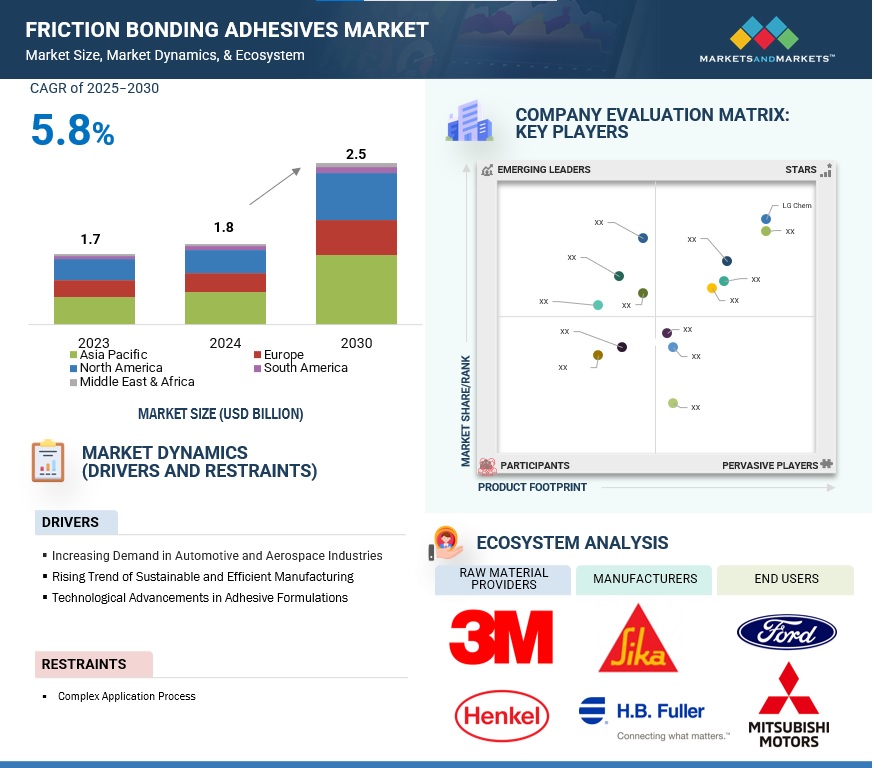

The friction bonding adhesive market is projected to grow from USD 1.8 billion in 2024 to USD 2.5 billion by 2030, at a CAGR of 5.8% between 2025 and 2030. The market for friction bonding adhesives includes the use of cutting-edge adhesives that provide great strength and endurance by connecting materials using friction-based techniques. For lightweight, effective, and environmentally friendly bonding solutions, these adhesives are widely employed in sectors like industrial, automotive, and aerospace. The market is driven by the growing need for high-performance materials, especially in the aerospace and automotive industries where strong, lightweight bonds are crucial. The use of friction bonding adhesives is further fueled by technological developments in adhesive formulations, the demand for cost-effective production methods, and the increased emphasis on environmental sustainability.

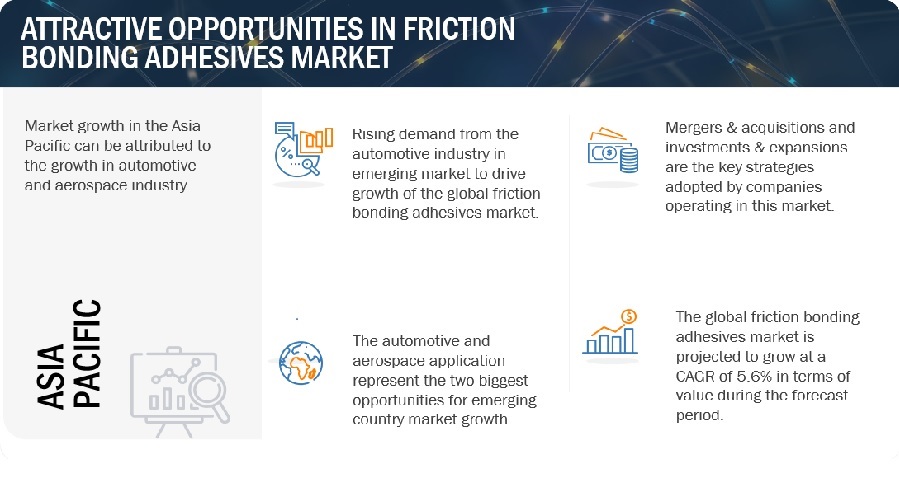

Attractive Opportunities in the Friction Bonding Adhesive Market

Source: Interviews with Experts, Secondary Sources, and MarketsandMarkets Analysis

Source: Interviews with Experts, Secondary Sources, and MarketsandMarkets Analysis

To know about the assumptions considered for the study, Request for Free Sample Report

Source: Expert Interviews, Secondary Sources, and MarketsandMarkets Analysis

Source: Expert Interviews, Secondary Sources, and MarketsandMarkets Analysis

Friction Bonding Adhesive Market Dynamics

Driver: Rising Demand in Automotive and Aerospace Industries

The automotive and aerospace industries require lightweight, high-strength materials to meet performance and fuel economy requirements. These industries benefit greatly from friction bonding adhesives, which provide dependable and robust bonding for a variety of materials, such as composites, metals, and polymers. These adhesives are essential to the production of contemporary cars and airplanes because they offer strong, effective solutions that aid in weight reduction while preserving structural integrity. The increasing demand for sophisticated, economical, and environmentally friendly production methods in these industries is supported by their capacity to effectively fuse various materials.

Restraints: High Cost of Advanced Adhesives

The high cost of friction bonding adhesives, particularly those designed for high-performance applications, can restrict their adoption in cost-sensitive markets. The premium pricing associated with these adhesives may hinder their widespread use, especially in regions where consumers prioritize affordability. This cost barrier limits their accessibility, particularly in industries or markets where budget constraints are a significant consideration, affecting overall market growth and adoption.

Opportunity: Growing demand for lightweight materials, technological advancements

The market for friction bonding adhesives has a lot of potential because of the rising need for strong, lightweight materials in sectors including automotive, and aerospace. New growth opportunities are made possible by technological developments including better adhesive formulations and environmentally friendly solutions. Further opportunities are also presented by the growing emphasis on sustainability and energy-efficient manufacturing techniques, since friction bonding adhesives lower waste and energy usage. The market's potential for growth is further enhanced by expanding applications in developing markets and industries including electronics and renewable energy.

Challenges: High material costs, complex application processes

The friction bonding adhesive market is posed with daunting challenges stemming from high costs of materials and complicated application processes. High costs associated with such friction bonding adhesives, especially those employed in high-performance applications, limit their adoption in industries and regions that are price sensitive. Furthermore, the use of such adhesives would often imply the availability of expensive equipment and skilled personnel to improve the cost of operation. In addition, the complexity of the process may lead to inefficiencies or mistakes when executed improperly, thus affecting the quality and performance of the product. All of these conditions act as deterrents against the popularity of friction bonding adhesives, especially in price-conscious or less technologically advanced markets.

Friction Bonding Adhesive Market Ecosystem

By type, Polyurethane is the fastest growing segment of the friction bonding adhesives market in terms of value

In value terms, the polyurethane segment is the fastest growing of all segments in the friction bonding adhesives market. Due to the superior combinations of durability, flexibility, and its resistance towards heat, moisture, and chemicals, polyurethane adhesive is favoured in many industries, including automotive, construction, and electronics, among others. Polyurethane adhesives have great bonding characteristics, especially for metals, plastics, and composites; hence they can be said to be a highly versatile type of polymer bond. The increasing need for strong, lightweight, and durable materials drives demand in the automotive and aerospace industries, so friction bonding adhesives based on polyurethane grow in role and value in their market.

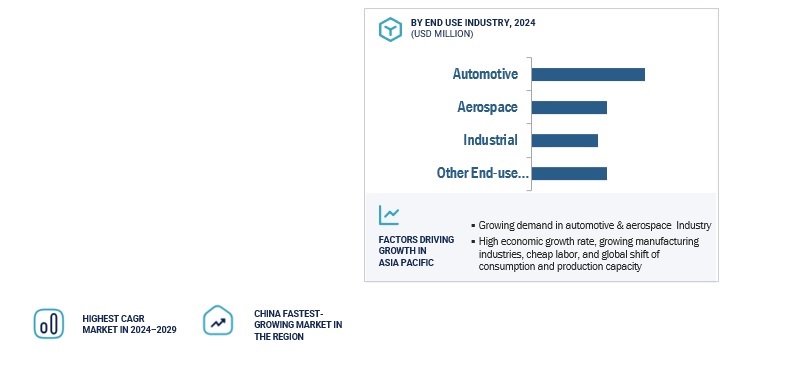

Aerospace segment is the fastest growing end use industry for the friction bonding adhesives market by end use industry in terms of value

In terms of market value, the aerospace segment is the fastest growing end-use industry for friction bonding adhesives. The continuous demand on aerospace concerns lightweight, durable, and high-performance materials for aircraft manufacture. Hence, advanced bonding solutions like friction bonding adhesives are increasingly being applied. These bonding adhesives provide superior reliability and strength when bonding metals, composites, and plastics in aerospace components. Improved fuel efficiency, reduced weight, and enhanced structural integrity are key driving forces for adoption of friction bonding adhesives in the aerospace sector.

Asia Pacific is the fastest-growing friction bonding adhesives market

The fastest growing area in terms of the friction bonding adhesives market is Asia Pacific. There is an increase in demand for the advanced bonding solutions due to the rapid industrialization of the region, especially in automotive, aerospace, and manufacturing sectors. Also, as countries like China, India, and Japan are focusing much on lightweight materials, fuel efficiency, and sustainable methods of manufacturing, the requirement of friction bonding adhesives increases. The expanding infrastructure and further emphasis on technological advancement add to the growth of this region in the market with respect to friction bonding adhesives as an important area for its use and innovation.

To know about the assumptions considered for the study, download the pdf brochure

Key Market Players

Henkel Ag & Co. KGAA (Germany), H.B. Fuller Company (US), Bostik (France), 3M Company (US), Sika Ag (Switzerland), Eastman Chemical (US) are the key players in the global friction bonding adhesive market.

Henkel AG & Co. KGaA is a German chemical and consumer goods corporation with its headquarters in Düsseldorf. The corporation was founded in 1876 and is a major force in the laundry, home care, adhesives, and cosmetics industries worldwide. The corporation employs about 53,000 people worldwide and conducts business in more than 140 countries. With an emphasis on providing value to its stakeholders, employees, and consumers, Henkel's corporate profile highlights its dedication to innovation, sustainability, and social responsibility.

Recent Developments in Friction Bonding Adhesive Market

- In 2020, Lubrizol, construction of a new Lucant plant. Lucant hydrocarbon synthetic fluid for shear and thermochemical resistance. These properties make it suitable to be used as polymer performance and viscosity modifier under the most extreme transport and industrial applications—including automotive driveline fluids, industrial lubricants and greases.

- In 2021, BASF SE, COSMOS-approved modifier, is now being added to the biopolymer portfolio of BASF.

To speak to our analyst for a discussion on the above findings, click Speak to Analyst

Frequently Asked Questions (FAQs):

What are the factors driving the growth of the friction bonding adhesive market?

The growing automotive and aerospace market.

What are the major applications for friction bonding adhesive?

The major applications of friction bonding adhesive are automotive, aerospace, and industrial.

Who are the major manufacturers of friction bonding adhesive?

Henkel Ag & Co. KGAA (Germany), H.B. Fuller Company (US), Bostik (France), 3M Company (US), Sika Ag (Switzerland), Eastman Chemical (US) are the key players in the global friction bonding adhesive market.

What are the reasons behind friction bonding adhesive gaining market share?

Friction bonding adhesive are gaining market share due to increasing demand from the Asia Pacific region.

Which is the largest region in the friction bonding adhesive market?

Asia Pacific is the largest region in the friction bonding adhesive market.

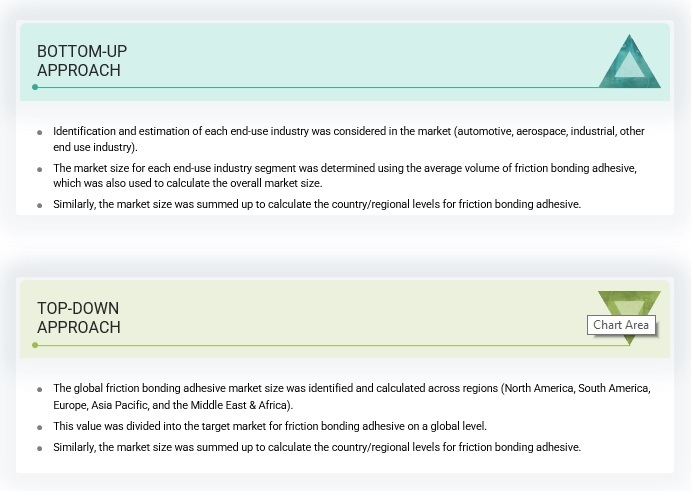

The study involved four major activities in order to estimating the current size of the Friction Bonding Adhesives market. Exhaustive secondary research conducted to gather information on the market. The next step was to conduct primary research to validate these findings, assumptions, and sizing with the industry experts across the value chain. Both top-down and bottom-up approaches were used to estimate the total market size. The market size of segments and subsegments was then estimated using market breakdown and data triangulation.

Secondary Research

Secondary sources include annual reports of companies, press releases, investor presentations, white papers, articles by recognized authors, and databases, such as D&B, Bloomberg, and Factiva; and publications and databases from associations, including Adhesive and Sealant Council (ASC), European Adhesive Tape Association (EATA), American Chemical Society (ACS), International Association of the Adhesives and Sealants Industry (IAASI).

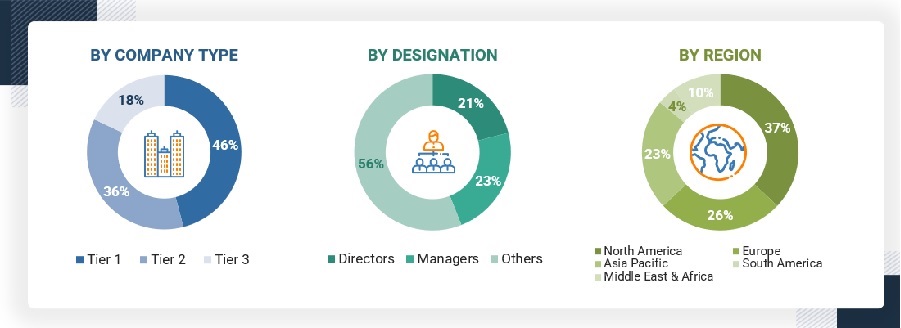

Primary Research

Extensive primary research was carried out after gathering information about Friction Bonding Adhesives market through secondary research. In the primary research process, experts from the supply and demand sides have been interviewed to obtain qualitative and quantitative information and validate the data for this report. Questionnaires, emails, and telephonic interviews were used to collect primary data. Primary sources from the supply side include industry experts, such as chief executive officers (CEOs), vice presidents (VPs), marketing directors, technology and innovation directors, and related key executives from various key companies and organizations operating in the Friction Bonding Adhesives market. Primary interviews were conducted to elicit information such as market statistics, revenue data collected from the products and services, market breakdowns, market size estimations, market forecasting, and data triangulation. Primary research also assisted in comprehending the various trends associated to type, end – use industry, and region.

The breakup of Primary Research:

To know about the assumptions considered for the study, download the pdf brochure

FRICTION BONDING ADHESIVES MANUFACTURERS

|

Friction Bonding Adhesives Manufaturers |

|

|

HENKEL AG & CO. KGAA |

DUPONT |

|

H.B. FULLER COMPANY |

EASTMAN CHEMICAL |

|

BOSTIK |

BOSTIK |

|

3M COMPANY |

SIKA GROUP |

Friction Bonding Adhesives Market Size Estimation

The following information is part of the research methodology used to estimate the size of the Friction Bonding Adhesives market. The market sizing of the Friction Bonding Adhesives market was undertaken from the demand side. The market size was estimated based on market size for Friction Bonding Adhesives in various technology.

Global Friction Bonding Adhesives Market Size: Bottom-Up Approach and Top-Down Approach

To know about the assumptions considered for the study, Request for Free Sample Report

Data Triangulation

After arriving at the overall market size, the market has been split into several segments. To complete the overall market engineering process and arrive at the exact statistics for all segments, the data triangulation and market breakdown procedures have been employed, wherever applicable. The data was triangulated by studying various factors and trends from the demand and supply sides. Along with this, the market size was validated using both the top-down and bottom-up approaches.

Market Definition

Friction Bonding Adhesive market friction bonding adhesives are advanced adhesive materials intended to be able to bond the materials by way of friction processes and hence maximize the holding strength and the durability. This type of binding adhesive is commonly used in automotive, aerospace, and manufacturing industries, which are looking for lighter, more efficient, and eco-friendly bonding solutions. The market for friction adhesives is growing as technology improves, as sustainability in manufacturing becomes a greater demand, and as stronger, more reliable bonding materials are expected.

Key Stakeholder

- End User

- Raw Material Suppliers

- Senior Management

- Procurement Department

Report Objectives:

- To define, describe, segment, and forecast the size of the friction bonding adhesives market based on width, type, end – use industry, and region.

- To forecast the market size of segments with respect to various regions, including North America, Europe, Asia Pacific, South America, Middle East & Africa, along with major countries in each region

- To identify and analyze key drivers, restraints, opportunities, and challenges influencing the growth of the friction bonding adhesives market

- To analyze technological advancements and product launches in the market

- To strategically analyze micromarkets, with respect to their growth trends, prospects, and their contribution to the market

- To identify financial positions, key products, and key developments of leading companies in the market

- To provide a detailed competitive landscape of the market, along with market share analysis

- To provide a comprehensive analysis of business and corporate strategies adopted by the key players in the market

- To strategically profile key players in the market and comprehensively analyze their core competencies

Available Customizations:

MarketsandMarkets offers the following customizations for this market report:

- Additional country-level analysis of the friction bonding adhesives market

- Profiling of additional market players (up to 5)

Product Analysis

- Product matrix, which gives a detailed comparison of the product portfolio of each company in the friction bonding adhesives market

Growth opportunities and latent adjacency in Friction Bonding Adhesive Market