Cross Laminated Timber : Regulations Drive the Future of Sustainable and Resilient Buildings

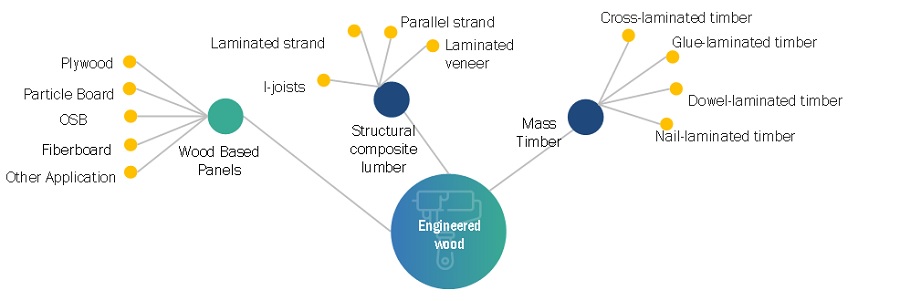

Cross Laminated Timber (CLT) is an engineered wood product that has gained acceptance as a sustainable and versatile construction material. CLT is made by layering dimensioned lumber boards or planks in perpendicular layers and bonding them together with adhesives, screws, or dowels. The alternating layers of wood create an exceptionally strong, stable panel that can be used for various structural and architectural applications. This innovative material has gained prominence in the construction industry due to its sustainability and design versatility.

Due to the new International Building Code 2021 adaptation, the demand for timber-based construction is expected to increase in non-residential sectors, such as low-rise and mid-rise buildings, majorly not more than eight stories, such as schools, offices, and other public places. In the US, timber is majorly used in the residential segment. Still, due to the introduction of the new international building code, use in the non-residential sector is expected to increase. High-rise buildings are expected to be constructed utilizing timber. These factors are expected to increase the demand for cross-laminated timber.

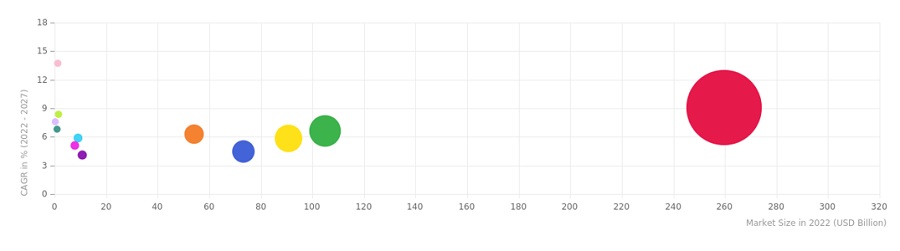

The global cross-laminated timber market size was USD 1.4 billion in 2023 and is forecasted to reach USD 2.6 billion by 2028, at a CAGR of 13.7%, between 2023 and 2028. The global cross-laminated timber market is witnessing high growth owing to technological advancements and growing demand in the North American region.

Major players operating in the cross-laminated timber include Mayr-Melnhof Holz (Austria), Stora Enso (Finland), Binderholz GmbH (Austria), Eugen Decker Holzindustrie KG (Germany), Hasslacher Holding GmbH (Austria), Schilliger Holz AG (Switzerland), KLH Massivholz GmbH (Austria), Structurlam Mass Timber Corporation (Canada), XLam NZ Limited (New Zealand), and others.

Current Challenges in the Construction Industry

- Environmental Concerns: The construction industry faces increasing pressure to reduce its environmental footprint. Traditional building materials, such as concrete and steel, are resource-intensive and contribute to high carbon emissions.

- Labor Shortages: A shortage of skilled labor in the construction sector has led to delays and increased project costs.

- Cost Overruns: Construction projects often exceed budgets due to unexpected expenses, including delays, material shortages, and design changes.

- Sustainability Demands: Regulatory changes and market demand have pushed for more sustainable, eco-friendly construction practices and materials.

- Material Limitations: Traditional materials like concrete and steel have design flexibility and energy efficiency limitations.

Cross Laminated Timber: A Solution to Industry Issues

-

Sustainable Characteristics of CLT

- Wood is a renewable resource.

- CLT production consumes less energy compared to concrete and steel.

- CLT sequesters carbon, reducing greenhouse gas emissions.

-

Labor and Time Efficiency

- CLT panels are prefabricated, reducing on-site labor requirements.

- Shorter construction schedules and faster project completion.

-

Cost-Effectiveness

- Competitive pricing, especially in regions with abundant wood resources.

- Fewer delays and cost overruns due to efficient production.

-

Design Flexibility

- CLT’s flexibility allows for innovative and sustainable architectural designs.

- Integrates well with other building systems.

-

Carbon Sequestration Benefits

- Wood in CLT stores carbon for the life of the building.

- It helps mitigate climate change.

The future of CLT in construction

The future of Cross Laminated Timber (CLT) in the construction industry appears promising, as it aligns with the industry’s growing emphasis on sustainability, efficiency, and design flexibility. Several key trends and factors point to a bright future for CLT:

Sustainability: Sustainability is a dominant theme in the construction industry. As a renewable and carbon-sequestering material, CLT fits well with the industry’s commitment to reducing environmental impact. The focus on sustainable building practices, such as LEED certification and net-zero energy buildings, is expected to drive the demand for CLT.

Regulatory Support: Many regions and countries update building codes and regulations to accommodate CLT. This regulatory support will facilitate its broader use in construction.

Urbanization: As urbanization continues, CLT’s capacity for efficient, tall building construction makes it a compelling choice for urban developers aiming to maximize available space.

Resilience and Disaster Mitigation: CLT’s potential for building resilient and earthquake-resistant structures is gaining attention, particularly in regions prone to natural disasters.

The sustainable path forward for the industry.

The construction industry is facing increasing pressure to adopt sustainable practices due to environmental concerns, resource scarcity, and a growing demand for eco-friendly building solutions. To pave a sustainable path forward for the construction industry, several key strategies and approaches can be implemented:

Green Building Standards and Certifications:

- Embrace and adhere to green building standards such as LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method).

- Seek certification for sustainable construction practices to demonstrate a commitment to eco-friendliness.

Energy Efficiency and Renewable Energy:

- Prioritize energy-efficient building designs and incorporate renewable energy sources like solar panels, wind turbines, and geothermal systems.

- Invest in high-efficiency HVAC, lighting, and insulation to reduce energy consumption.

Waste Management and Recycling:

- Implement effective waste management strategies to reduce construction waste and divert materials from landfills.

- Encourage recycling and repurposing of materials wherever possible.

Smart and Sustainable Design:

- Embrace sustainable design principles that optimize natural light, ventilation, and thermal comfort to reduce energy consumption.

- Implement smart building technologies to efficiently control lighting, HVAC, and security systems.

Customer Problems Pertaining to the Construction Industry

Title: The Largest Cross-Laminated Timber Structure in America

America’s largest cross-laminated timber structure is to be found in the state of Oregon. The new building had a cross-laminated timber roof, floors, and simplified support for the exterior façade, with glulam for the post and beam frame and columns. Completion took 14 months, with only 12 weeks for the timber erection, saving four months of construction time and 4% in costs.

Cross-laminated timber was chosen over a conventional structural steel frame for First Tech Federal Credit Union’s five-floor, 156,000-square-foot building – requiring a clean look with no visible mechanical systems. Achieving this required more than 4,200 mechanical, electrical, and plumbing penetrations in cross-laminated timber.

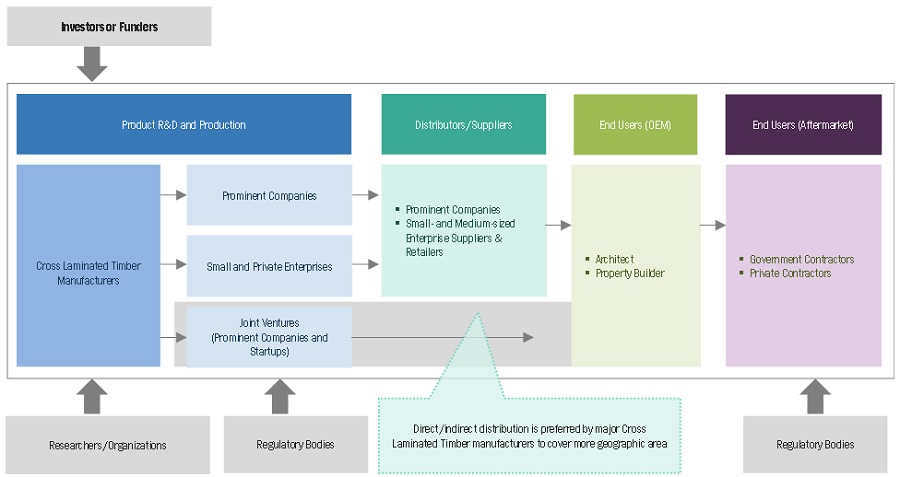

Cross-Laminated Timber Market Ecosystem

MarketsandMarkets coverage of high-growth niche market relevant to Cross-laminated Timber

Growth opportunities and latent adjacency in Cross Laminated Timb