Composite Tooling Market by Fiber Type (Carbon and Glass), Resin Type (Epoxy, BMI, and others), Form (Fabric and Prepreg), and Application (Aerospace & Defense, Wind, Automotive, and Others) - Global Forecast to 2021

The composite tooling market is projected to reach USD 551.8 Million by 2021, at a CAGR of 7.35%. Composite tooling is becoming crucial in automotive, aerospace, wind, and among others. The need for superior quality tooling and strong and rigid composite components is increasing the demand of composite tooling. In this study, years considered for estimating market size of composite tooling are:

- Historical Year – 2014

- Base Year – 2015

- Estimated Year – 2016

- Projected Year – 2021

- Forecast Period – 2016 to 2021

2015 has been considered the base year for company profiles. Whenever information was unavailable for the base year, the prior year has been considered.

Composite Tooling Market Report Objectives of the Study

- To define, describe, and forecast the composite tooling market size, in terms of value and volume

- To identify and measure the composite tooling market by types of resin, applications, fibers, form, and region

- To analyze significant region-specific market trends in North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa (ME&A) and country-specific trends in the U.S., Germany, France, the U.K., China, and India.

- To provide detailed information regarding the major factors influencing the growth of the market (drivers, restraints, opportunities, industry-specific challenges, and burning issues)

- To strategically profile and analyze the key market players and their core competencies*

- To analyze recent market developments such as partnerships, joint ventures, and mergers & acquisitions of the composite tooling market

Note*: Core competencies of the companies are determined in terms of SWOT analysis and key strategies adopted by them to sustain their position in the market

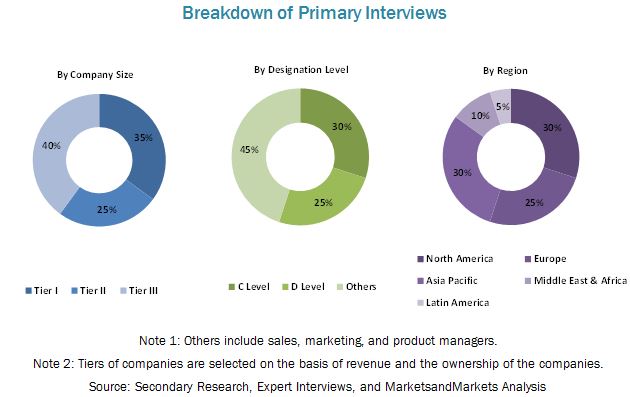

Various secondary sources such as company websites, encyclopedias, directories, and databases have been used to understand and gain insights for the composite tooling market. Experts from top composite tooling companies have been interviewed to verify and collect critical information and to assess the trend of the composite tooling market during the forecast period. The top-down, bottom–up, and data triangulation approaches have been implemented to calculate the exact values of the overall parent and individual market sizes.

To know about the assumptions considered for the study, download the pdf brochure

Key Players in Composite Tooling Market

The market of composite tooling has a diversified ecosystem including the downstream stakeholders such as manufacturers, vendors, end users, and government organizations. Some of the major raw material suppliers are Royal TenCate N.V. (Netherlands), Gurit Holding AG (Switzerland), Airtech Advanced Materials Group (U.S.), Hexcel Corporation (U.S.), Solvay S.A. (Belgium), and others.

This study focuses on the top investment pockets, which would help the stakeholders to understand and analyze the emerging trends of the composite tooling market.

Target Audience in Composite Tooling Market

- Composite part manufacturers

- Fiber manufacturers for composites

- Resin manufacturers for composite

- Aerospace industry

- Automotive industry

- Wind industry

Composite Tooling Market Report Scope

This research report categorizes the market of composite tooling based on type of fiber reinforcement, resin type, form, application, and region. It forecasts revenue growth and analysis of trends in each of the submarkets till 2021.

On the Basis of Fiber Reinforcement Type

- Glass fiber

- Carbon fiber

On the Basis of Resin Type

- Epoxy

- BMI

- Others (polyester and vinyl ester)

On the Basis of Form

- Prepreg

- Fabric

On the Basis of Application

- Aerospace

- Automotive

- Wind

- Others

On the Basis of Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa (ME&A)

Composite Tooling Market Report Available Customizations

With the given market data, MarketsandMarkets offers customizations according to the specific needs of the companies. The following customization options are available for the report:

Composite Tooling Market Product Analysis

- Product matrix, which gives a detailed comparison of the product portfolio of each company

Composite Tooling Market Regional Analysis

- Further breakdown of the composite tooling market in North America, Europe, Asia-Pacific, South America, and the Middle East & Africa

Composite Tooling Market Company Information

- Detailed analysis and profiling of additional market players

The market size of composite tooling is projected to reach USD 551.8 Million by 2021, at a CAGR of 7.35%, between 2016 and 2021. The increasing demand for lightweight and precision tooling of composites in wind, aerospace, automotive, and other applications are the key factors responsible for the growth of the composite tooling market.

The global composite tooling market is segmented into type of fiber reinforcement, resin type, form, application, and region. The composite tooling market, by type of fiber reinforcement is further segmented into glass fiber and carbon fiber. Carbon fiber-based composite tooling accounted the largest market size in 2015, in terms of value, owing to growing demand from applications such as primary & secondary structures in aerospace and automotive and wind turbine blades.

The composite tooling market, by resin type is segmented into epoxy, BMI (bismalemide) and others. The epoxy-based composite tooling is expected to grow faster during the forecast period due to excellent mechanical, electrical, and high temperature resistance properties. Similarly, BMI resin is expected to account for the second highest market share after epoxy resin during the forecast period. The curing temperature of BMI is higher than those of epoxy and phenolic resins. BMI resins enhance the design flexibility of composite tooling, elongate the tool life, and also offer improved dimensional stability

The major applications included in the composite tooling market include aerospace, wind, automotive, and others. Aerospace constituted a major portion in the composite tooling market, by value. The high growth of aerospace application is attributed to extensive use of composite tooling for making strong composite components. Owing to the increasing use of composites in the aerospace industry, the demand for superior composite tooling is all set to rise. Composite tooling enables having wider tool design freedom and high flexibility.

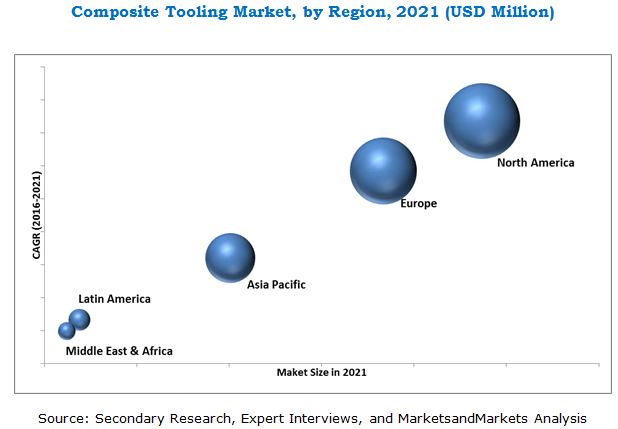

North America is expected to be the fastest-growing market for composite tooling between 2016 and 2021. Growth in the wind industry, large investment by government in the aerospace industry, and new product launch by various leading players are a few factors leading to the growth of the composite tooling market in this region. The U.S. leads the market of composite tooling in North America.

The composite tooling market size is rapidly growing, in terms of value. However, a few factors restrain its growth such as high competition from invar and other materials.

Key Composite Tooling Market Industry Players

The companies such as Royal TenCate N.V. (Netherland), Hexcel Corporation (U.S.), Gurit Holding AG (Switzerland), Airtech Advanced Materials Group (U.S.), Solvay S.A. (Belgium), Janicki Industries (U.S.), and Solvay SA Group (Belgium) are the key market players in the composite tooling market. They have been adopting various organic and inorganic growth strategies such as agreements & partnerships, new product launches, and expansions to enhance their share in the composite tooling market.

Frequently Asked Questions (FAQ):

What is the Composite Tooling Market growth?

Growth of Composite Tooling Market - At a CAGR of 7.35%, between 2016 and 2021.

Who leading market players in Composite Tooling industry?

Some of the key global players prevailing in the composite tooling market are Royal TenCate N.V. (Netherlands), Hexcel Corporation (U.S.), Gurit (Switzerland), Solvay S.A. (Belgium).

How big is the Composite Tooling Market?

The composite tooling market is projected to reach USD 551.8 Million by 2021.

Which segments are covered in Composite Tooling Market report?

By Fiber Type (Carbon and Glass), Resin Type (Epoxy, BMI, and others), Form (Fabric and Prepreg) & Application (Aerospace & Defense, Wind, Automotive).

To speak to our analyst for a discussion on the above findings, click Speak to Analyst

Table of Contents

1 Introduction (Page No. - 14)

1.1 Objectives of the Study

1.2 Market Definition

1.3 Scope of the Study

1.3.1 Markets Covered

1.3.2 Years Considered in the Report

1.4 Currency

1.5 Package Size

1.6 Stakeholders

1.7 Limitations

2 Research Methodology (Page No. - 17)

2.1 Research Data

2.1.1 Secondary Data

2.1.1.1 Key Data From Secondary Sources

2.1.2 Primary Data

2.1.2.1 Key Data From Primary Sources

2.2 Market Size Estimation

2.2.1 Bottom-Up Approach

2.2.2 Top-Down Approach

2.3 Data Triangulation

2.3.1 Research Assumptions

3 Executive Summary (Page No. - 24)

4 Premium Insights (Page No. - 28)

4.1 Attractive Growth Opportunities in the Composite Tooling Market

4.2 Composite Tooling Market, By Application

4.3 Aerospace Application to Account the Largest of the Composite Tooling Market, 2016–2021

4.4 Composite Tooling Market, By Country

4.5 Composite Tooling Market, By Form

5 Market Overview (Page No. - 32)

5.1 Introduction

5.2 Market Dynamics

5.2.1 Drivers

5.2.1.1 Light Weight and Precision Tooling of Composite Tools

5.2.2 Restraints

5.2.2.1 High Competition From Invar and Other Materials

5.2.3 Opportunities

5.2.3.1 Adoption of 3D Printing in Composite Tooling

5.2.4 Challenges

5.2.4.1 to Increase the Production Cycle Time of Composite Tooling

5.3 Porter’s Five Forces Analysis

5.3.1 Threat of New Entrants

5.3.2 Threat of Substitutes

5.3.3 Bargaining Power of Suppliers

5.3.4 Bargaining Power of Buyers

5.3.5 Intensity of Competitive Rivalry

6 Macro Economic Overview and Key Trends (Page No. - 40)

6.1 Introduction

6.2 Trends and Forecast of GDP

6.3 Per Capita GDP vs Per Capita Composite Materials Demand

6.4 Trends of Wind Energy Industry

6.5 Trends of Aerospace Industry

6.6 Trends of Automotive Industry

7 Composite Tooling Market, By Application (Page No. - 46)

7.1 Introduction

7.2 Aerospace

7.2.1 3D Printing of Aerospace Tooling

7.3 Wind

7.3.1 Wind Blade Master Plug

7.3.2 Wind Blade Mould

7.3.3 Wind Blade Hinge System

7.4 Automotive

7.4.1 Exterior

7.4.2 Interior

7.5 Others

7.5.1 Marine

8 Composite Tooling Market, By Resin Type (Page No. - 55)

8.1 Introduction

8.2 Epoxy

8.3 BMI

8.4 Other Resins

8.4.1 Vinyl Ester

8.4.2 Polyester

8.4.3 Benzoxazine

9 Composite Tooling Market, By Fiber Type (Page No. - 62)

9.1 Introduction

9.1.1 Glass Fiber

9.1.2 Carbon Fiber

9.1.2.1 Continuous Carbon Fiber

9.1.2.2 Chopped Carbon Fiber

10 Composite Tooling Market, By Form Type (Page No. - 67)

10.1 Introduction

10.1.1 Fabric

10.1.2 Prepreg

11 Regional Analysis (Page No. - 72)

11.1 Introduction

11.2 North America

11.2.1 Canada

11.2.2 U.S.

11.3 Europe

11.3.1 Germany

11.3.2 France

11.3.3 Italy

11.3.4 U.K.

11.3.5 Austria

11.3.6 Sweden

11.3.7 Netherlands

11.3.8 Spain

11.4 Asia-Pacific

11.4.1 China

11.4.2 India

11.4.3 Japan

11.4.4 South Korea

11.4.5 Australia & New Zealand

11.4.6 Malaysia

11.4.7 Thailand

11.5 Latin America

11.5.1 Brazil

11.5.2 Mexico

11.5.3 Argentina

11.5.4 Chile

11.6 ME&A

11.6.1 UAE

11.6.2 South Africa

11.6.3 Saudi Arabia

12 Competitive Landscape (Page No. - 93)

12.1 Overview

12.2 Expansions: Most Popular Growth Strategy

12.3 Maximum Developments in 2014

12.4 Competitive Landscape

12.4.1 Expansions

12.4.2 New Product Launches

12.4.3 Agreements

12.4.4 Acquisitions

13 Company Profiles (Page No. - 99)

(Overview, Financial*, Products & Services, Strategy, and Developments)

13.1 Gurit Holding AG

13.2 Royal Tencate N.V.

13.3 Hexcel Corporation

13.4 Airtech Advanced Materials Group

13.5 Solvay S.A. (Cytec Industries, Inc.)

13.6 Janicki Industries, Inc.

13.7 Formaplex

13.8 Hydrojet, Inc.

13.9 Machinists, Inc.

13.10 AIP Aerospace, LLC

13.11 Other Companies

*Details Might Not Be Captured in Case of Unlisted Companies

14 Appendix (Page No. - 116)

14.1 Insights From Industry Experts

14.2 Discussion Guide

14.3 Introducing RT : Real Time Market Intelligence

14.4 Knowledge Store: Marketsandmarkets’ Subscription Portal

14.5 Available Customizations

14.6 Related Reports

List of Tables (75 Tables)

Table 1 Composite Tooling Market Size (Volume and Value), 2016–2021

Table 2 Market, By Fiber Type

Table 3 Market, By Form

Table 4 Market, By Resin

Table 5 Market, By Application

Table 6 Trends and Forecast of GDP, USD Billion (2015–2021)

Table 7 Per Capita GDP vs Per Capita Composite Materials Demand, 2015

Table 8 Market of New Airplanes, 2015-2034

Table 9 Automotive Production, Million Units (2011-2015)

Table 10 Composite Tooling Market Size, By Application, 2014–2021 (USD Million)

Table 11 Market Size, By Application, 2014–2021 (Ton)

Table 12 Market Size in Aerospace Application, By Region, 2014–2021 (USD Million)

Table 13 Market Size in Aerospace Application, By Region, 2014–2021 (Ton)

Table 14 Market Size in Wind Application, By Region, 2014–2021 (USD Million)

Table 15 Market Size in Wind Energy Application, By Region, 2014–2021 (Ton)

Table 16 Market Size in Automotive Application, By Region, 2014–2021 (USD Million)

Table 17 Market Size in Automotive Application, By Region, 2014–2021 (Ton)

Table 18 Market Size in Others Application, By Region, 2014–2021 (USD Million)

Table 19 Market Size in Others Application, By Region, 2014–2021 (Ton)

Table 20 Market Size, By Resin Type, 2014-2021 (USD Million)

Table 21 Market Size, By Resin Type, 2014-2021 (Ton)

Table 22 Epoxy-Based Composite Tooling Market Size, By Region, 2014-2021 (USD Million)

Table 23 Epoxy-Based Market Size, By Region, 2014-2021 (Ton)

Table 24 BMI Resin-Based Composite Tooling Market Size, By Region, 2014-2021 (USD Million)

Table 25 BMI Resin-Based Market Size, By Region, 2014-2021 (Ton)

Table 26 Other Resins-Based Composite Tooling Market Size, By Region, 2014-2021 (USD Million)

Table 27 Other Resins-Based Market Size, By Region, 2014-2021 (Ton)

Table 28 Composite Tooling Market Size, By Fiber Type,2014-2021 (USD Million)

Table 29 Market Size, By Fiber Type, 2014-2021 (Ton)

Table 30 Glass Fiber Composite Tooling Market Size, By Region, 2014-2021 (USD Million)

Table 31 Glass Fiber Market Size, By Region 2014-2021 (Ton)

Table 32 Carbon Fiber Composite Tooling Market Size, By Region, 2014-2021 (USD Million)

Table 33 Carbon Fiber Market Size, By Fiber Type, 2014-2021 (Ton)

Table 34 Composite Tooling Market Size, By Form Type,2014-2021 (USD Million)

Table 35 Market Size, By Form Type, 2014-2021 (Ton)

Table 36 Fabric Composite Tooling Market Size, By Region, 2014-2021 (USD Million)

Table 37 Fabric Market Size, By Region 2014-2021 (Ton)

Table 38 Prepreg Composite Tooling Market Size, By Region, 2014-2021 (USD Million)

Table 39 Prepreg Market Size, By Fiber Type, 2014-2021 (Ton)

Table 40 Composite Tooling Market Size, By Region, 2014–2021 (USD Million)

Table 41 Market Size, By Region, 2014–2021 (Ton)

Table 42 North America: Composite Tooling Market Size, By Country, 2014–2021 (USD Million)

Table 43 North America: Market Size, By Country, 2014–2021 (Ton)

Table 44 North America Market Size, By Fiber Type, 2014–2021 (USD Million)

Table 45 North America Market Size, By Fiber Type, 2014–2021 (Ton)

Table 46 North America Market Size, By Application, 2014–2021 (USD Million)

Table 47 North America Market Size, By Application, 2014–2021 (Ton)

Table 48 Europe: Composite Tooling Market Size, By Country, 2014–2021 (USD Million)

Table 49 Europe: Market Size, By Type of Fiber Reinforcement, 2014–2021 (Ton)

Table 50 Europe Market Size, By Fiber Type, 2014–2021 (USD Million)

Table 51 Europe Market Size, By Fiber Type, 2014–2021 (Ton)

Table 52 Europe Market Size, By Application, 2014–2021 (USD Million)

Table 53 Europe Market Size, By Application, 2014–2021 (Ton)

Table 54 Asia-Pacific: Composite Tooling Market Size, By Country, 2014–2021 (USD Million)

Table 55 Asia-Pacific: Market Size, By Country, 2014–2021 (Ton)

Table 56 Asia-Pacific Market Size, By Fiber Type, 2014–2021 (USD Million)

Table 57 Asia-Pacific Market Size, By Fiber Type, 2014–2021 (Ton)

Table 58 Asia-Pacific Market Size, By Application, 2014–2021 (USD Million)

Table 59 Asia-Pacific Market Size, By Application, 2014–2021 (Ton)

Table 60 Latin America: Composite Tooling Market Size, By Country, 2014–2021 (USD Million)

Table 61 Latin America: Market Size, By Country, 2014–2021 (Ton)

Table 62 Latin America Market Size, By Fiber Type, 2014–2021 (USD Million)

Table 63 Latin America Market Size, By Fiber Type, 2014–2021 (Ton)

Table 64 Latin America Market Size, By Application, 2014–2021 (USD Million)

Table 65 Latin America Market Size, By Application, 2014–2021 (Ton)

Table 66 ME&A: Composite Tooling Market Size, By Country, 2014–2021 (USD Million)

Table 67 ME&A: Market Size, By Country, 2014–2021 (Ton)

Table 68 ME&A: Market Size, By Fiber Type, 2014–2021 (USD Million)

Table 69 ME&A: Market Size, By Fiber Type, 2014–2021 (Ton)

Table 70 ME&A: Market Size, By Application, 2014–2021 (USD Million)

Table 71 ME&A: Market Size, By Application, 2014–2021 (Ton)

Table 72 Expansions, 2011–2016

Table 73 New Product Launches, 2011–2016

Table 74 Agreements, 2011–2016

Table 75 Acquisitions, 2011–2016

List of Figures (43 Figures)

Figure 1 Composite Tooling: Market Segmentation

Figure 2 Composite Tooling Market: Research Methodology

Figure 3 Market Size Estimation Methodology: Bottom-Up Approach

Figure 4 Market Size Estimation Methodology: Top-Down Approach

Figure 5 Data Triangulation Methodology

Figure 6 Aerospace Industry to Drive the Composite Tooling Market, in Terms of Value, 2016–2021

Figure 7 North America Dominated the Composite Tooling Market, in Terms of Value (2015)

Figure 8 France to Be the Fastest Growing Composite Tooling Market From 2016 to 2021

Figure 9 Significant Growth the Composite Tooling Market

Figure 10 Aerospace is the Fastest-Growing Application in the Composite Tooling Market

Figure 11 North America is the Largest Composite Tooling Market, in Terms of Value

Figure 12 North America to Be the Fastest-Growing Market, 2016–2021

Figure 13 Prepreg is Most Preferred Form of Composite Tooling Market, 2016 - 2021

Figure 14 Drivers, Restraints, Opportunities, and Challenges in Composite Tooling Market

Figure 15 Porter’s Five Forces: Threat of New Entrants is Moderate-To-High Due to Low Entry Barriers

Figure 16 Per Capita GDP vs Per Capita Composite Materials Demand

Figure 17 Wind Energy Installed Capacity, Mw (2014–2015)

Figure 18 New Airplanes Deliveries, By Region, 2015-2034

Figure 19 Automotive Production in Key Countries, Million Units (2011 vs 2015)

Figure 20 Composite Tooling Market in Aerospace Application to Witness Highest Growth, 2016 - 2021

Figure 21 North America to Drive the Composite Tooling Market in Aerospace Application, 2016 - 2021

Figure 22 Europe to Drive the Composite Tooling Market in Automotive Application Between 2016 and 2021

Figure 23 Epoxy Resin Expected to Completely Dominate Composite Tooling Market, 2016 - 2021

Figure 24 Epoxy-Based Composite Tooling Market in North America Expected to Grow at A Faster Rate, 2016 - 2021

Figure 25 Carbon Fiber to Dominate Composite Tooling Market, During Forecast Period, 2016-2021

Figure 26 North American Region Expected to Bolster Growth of Composite Tooling Market, 2016 - 2021

Figure 27 Prepreg Form to Have Largest Share in Composite Tooling Market, 2016 -. 2021

Figure 28 North American Region Expected to Bolster Growth of Composite Tooling Market, 2016 - 2021

Figure 29 North America to Drive the Composite Tooling Market, 2016–2021

Figure 30 Composite Tooling Market Snapshot: U.S. to Lead the Composite Tooling Market in North America

Figure 31 Market Snapshot: Germany to Bolster Growth of the Composite Tooling Market in Europe

Figure 32 Market Snapshot: China is the Most Lucrative Market in Asia-Pacific

Figure 33 Market Snapshot: Brazil to Drive the Composite Tooling Market in Latin America, 2016 - 2021

Figure 34 Market Snapshot: UAE to Grow With the Highest CAGR in the Me&A,2016-2021

Figure 35 Companies Adopted Expansions as Key Growth Strategy in Last Five Years (2011–2016)

Figure 36 Major Growth Strategies in Composite Tooling Market, 2011–2016

Figure 37 Developments in Composite Tooling Market, 2011–2016

Figure 38 Gurit Holding AG: Company Snapshot

Figure 39 Gurit Holding AG: SWOT Analysis

Figure 40 Royal Tencate N.V.: Company Snapshot

Figure 41 Hexcel Corporation: Company Snapshot

Figure 42 Solvay S.A.: Company Snapshot

Figure 43 Solvay SA: SWOT Analysis

Growth opportunities and latent adjacency in Composite Tooling Market