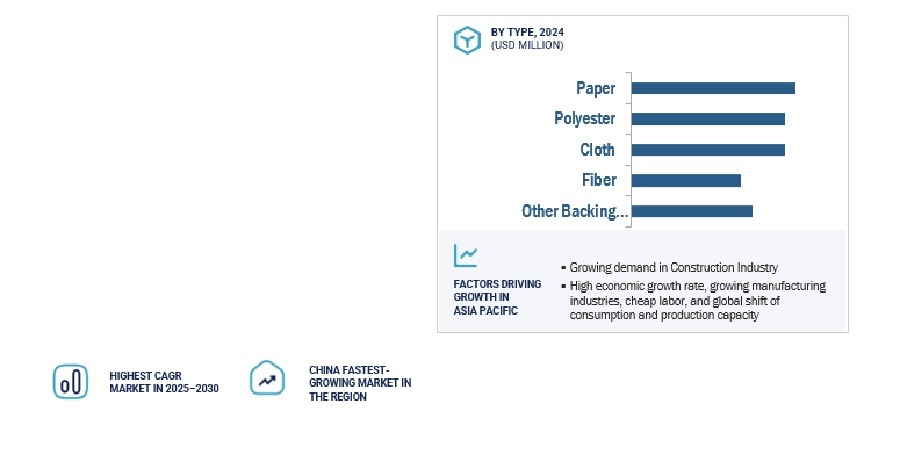

Coated Abrasive Market by Product Type (Belts, Discs, Rolls, Sheets, Others Product Type), Material Type (Aluminum Oxide, Silicon Carbide, Zirconia Alumina, Ceramic Alumina, Other Material Type), Backing Material (Cloth, Paper, Fiber, Polyester, Other Backing Material), End-use Industry (Construction, Woodworking, Automotive, Aerospace, Metal Working, Other End-Use Industries), and Region - Global Forecast to 2030

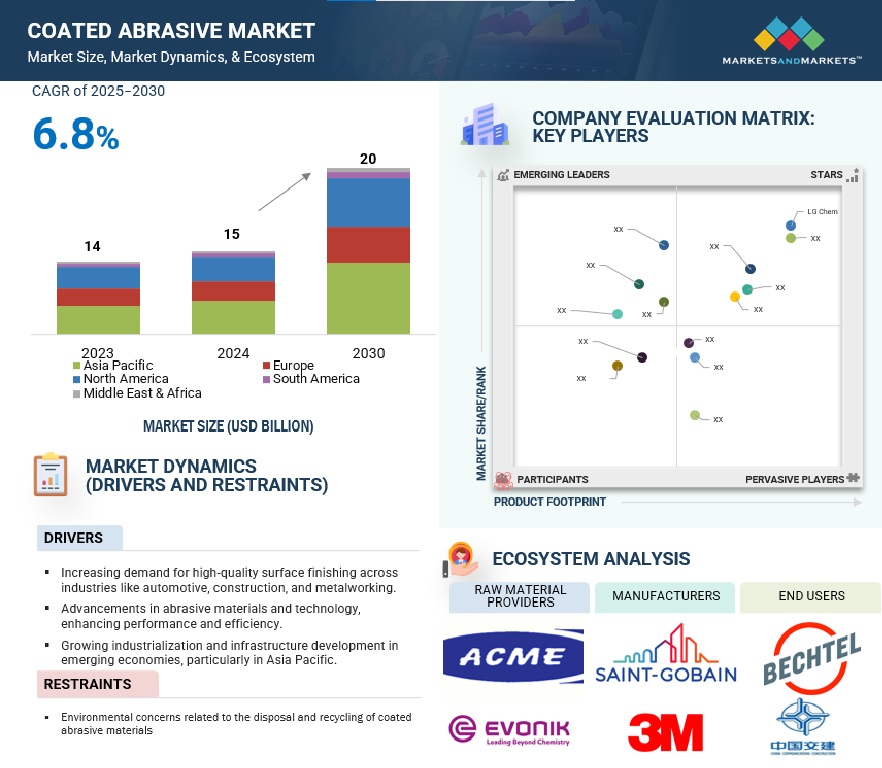

The Coated abrasive market is projected to grow from USD 15 billion in 2024 to USD 20 billion by 2030, at a CAGR of 6.8% between 2025 and 2030. The coated abrasives market is predominantly driven by its demand in different end-use industries like automobiles, construction, and woodworking. Coated abrasives are a crucial component in the automotive industry for surface preparation, grinding, and polishing, resulting in high-quality finishes of the vehicle parts. Coated abrasives are also a part of the construction industry, where such abrasives are used for sanding and smoothing wood, metal, and concrete. These are critical abrasives for precision finishing in metalworking, resulting in improving the performance as well as the aesthetics of the metal products.

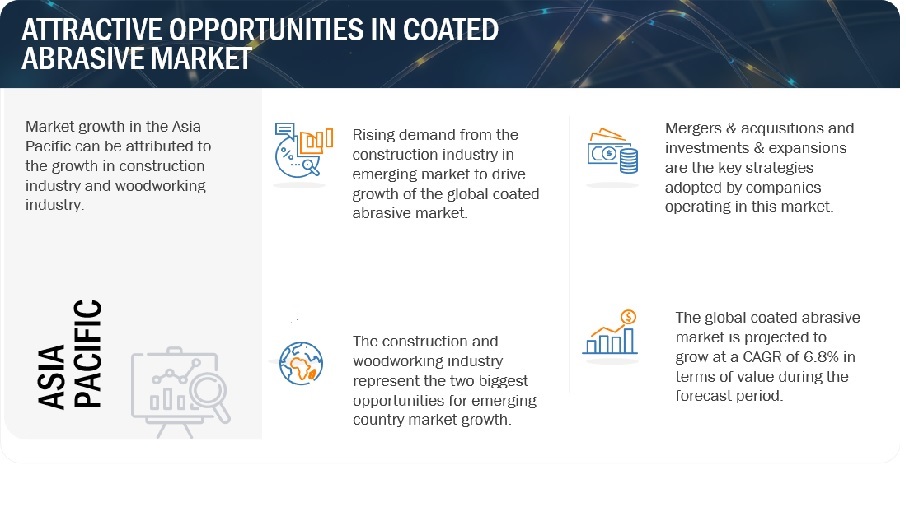

Attractive Opportunities in the Coated Abrasive Market

Source: Interviews with Experts, Secondary Sources, and MarketsandMarkets Analysis

Source: Interviews with Experts, Secondary Sources, and MarketsandMarkets Analysis

To know about the assumptions considered for the study, Request for Free Sample Report

Source: Expert Interviews, Secondary Sources, and MarketsandMarkets Analysis

Source: Expert Interviews, Secondary Sources, and MarketsandMarkets Analysis

Coated Abrasive Market Dynamics

Driver: Increasing demand for high-quality surface finishing across industries like automotive, construction, and metalworking

High-quality surface finishing has gained increased demand worldwide from industries like automotive, construction, and metalworking, which increase the value in the coated abrasive market. In automotive manufacturing, surface finish must be executed well for both aesthetic and performance purposes because it reflects paint adhesion durability and overall general appearance. In construction, the same coatings, sanding, and polishing techniques are applied to wood, concrete, and metals, among others, to give such materials functionality and some refined finish. Coated abrasives are equally needed in metalworking for achieving such smooth, polished surfaces and edge finishes; examples of applications are tool manufacturing, machinery, and metal components. Hence, all these industries with their increasing size and demand generate a growing need for such products that perform superiorly using such outstanding abrasives for consistent, reliable surface treatment. This demand augments overall market growth because quality and durability concerns have increased within these sectors.

Restraints: Environmental concerns related to the disposal and recycling of coated abrasive materials

Environmental issues associated with the disposal and recycling of coated abrasives thereby restraining the market. Most coated abrasives contain synthetic resins, and materials that are not easy to recycle propound disposal waste. Since these products are used in the preparation of surfaces, generated dust, debris, and particles can be harmful to the environment when disposed of inappropriately. The limited options for recycling abrasive materials add more waste to landfills. There is now a great deal of pressure on the coated abrasive industry to innovate and develop solutions that have less environmental impact because of increasing emphasis on sustainability.

Opportunity: Innovation in Sustainable, Recyclable Coated Abrasives

The major opportunities for the coated abrasive market is the demand for green solution. Industries are striving to be more eco-friendly, and so are abrasives required to be recyclable or biodegradable or even made from renewable materials. Environmentally friendly coated abrasives can also reduce waste and the overall carbon footprint of surface finishing processes. Incorporating such measures will comply with the global environmental standards and customer preferences for manufacturers, thus growing market opportunities. This change to a sustainable product adds wings to market growth and drives up avenues for new innovation and markets even in corporate responsibility terms for coated abrasive manufacturers.

Challenges: Price volatility of raw material

Price volatility of raw materials is key challenge for the coated abrasive market. Fluctuation in the cost of key raw materials such as abrasive grains, backing materials, and resins results in unpredictable production costs. Price variations like these affect manufacturers' ability to keep their pricing strategies consistent from one month to the next and profit margins. When raw material costs rise, they can cause increased product prices, which can limit demand, especially in price-sensitive industries. Manufacturers must focus on disruption management of supply chains moving forward toward securing raw material sources to mitigate this challenge.

COATED ABRASIVE MARKET ECOSYSTEM

The ecosystem of the coated abrasives market is dominated by different supply chains through which it incorporates the raw materials to the end users. The raw material suppliers provide the important components: abrasive grains (as, aluminum oxide, silicon carbide), backing materials (paper, cloth, film), and bonding agents. They then process and manufacture coated abrasive producers who apply abrasives to backing materials, thus producing sandpaper, grinding discs, belts, and sheets. Thereafter, these products are sold to wholesalers and distributors for end users, among them automobile, construction, metalworking, woodworking, and electronics industries. The end users utilize coated abrasives during surface finishes, polishing, and grinding. These processes are required for producing high-quality products for their respective industries. The market is thus driven by advances in technology, increasing industrial demand, and the urge to have efficient solutions for durable surface treatments.

By Material type, Aluminium Oxide holds one of the largest share of coated abrasive market in terms of value

By virtue of Excellent hardness, durability and versatility, aluminum oxide occupies in value a place among the largest shares of the coated abrasive market. Such applications of such materials include metalworking, woodworking, and automotive operations, where high-performance-abrasives are required. It is efficient in surface preparation, grinding, and polishing; long-lasting, and consistent performance. Cost-effective-along with an ability to cover a broad range of materials-all makes it much preferred by the manufacturers speaking to why the product further commands such an outstanding share within the market for coated abrasives.

Automotive segment holds one of the largest shares of the coated abrasive market by end-use industry in terms of value

The automotive segment takes a significantly value share from the coated abrasive market in terms of end use industry since there is high demand for surface finishing, polishing, and grinding during vehicle manufacture. Coated abrasives are critical in all car manufacturing processes, including sanding body panels, preparing surfaces for paint, and refining metal components for precision. To ensure a smooth finish, their durability, and aesthetic appearance, the automobile industry needs high-quality abrasives, and this enhances their customer demand significantly. In addition to this, further growth of the industry itself, such as with the increased potential in electric vehicles will fuel demand for advanced coated abrasives that add up the already large figure for this segment.

Asia Pacific is the fastest-growing coated abrasive market

Asia Pacific is the fastest growing market for coated abrasives due to the rounded increase in the Industry, manufacturing activities, and growing infrastructure developments. This demand is typically satisfied through China, India, and Japan, with high demand coming from automotive, construction, metal working, and electronics industries. The region's growing middle class coupled with increased demand for consumer goods drives the need for surface finishing to be of high quality. In addition to this, cost-competitive manufacturing with raw materials easily available contributes to the Asia Pacific hub for abrasive manufacturing. Proper growth in manufacturing, together with technology revolution, has made Asia Pacific become the fastest in growth in coated abrasive market.

To know about the assumptions considered for the study, download the pdf brochure

Key Market Players

SAINT-GOBAIN (France), 3M(US), ROBERT BOSCH GMBH (Germany), FUJIMI INCORPORATED(Japan), ASAHI DIAMOND INDUSTRIAL CO. LTD(Japan), CABOT MICROELECTRONICS CORPORATION(US), are the key players in the global coated abrasive market.

Saint-Gobain is a company producing materials and solutions enhancing daily human life, which originated in 1665 and has its headquarters in Paris, France. The company's operations run in over 70 countries worldwide and service the various industries such as construction, automotive, aerospace, and healthcare.

Recent Developments in Coated Abrasive Market

- In May 2023, 3M collaborated with AV&R, a provider of industrial automation services, to offer next-generation robotic systems for automating surface finishing processes in the manufacturing sector. This collaboration combines 3M's expertise as a leading manufacturer and supplier of abrasive products with AV&R's automation capabilities in surface finishing.

- In April 2022, Saint-Gobain Abrasives introduced its new Norton Abrasive Process Solutions (APS) Program. The program was established to help customers determine the optimal grinding or finishing solution for various applications.

To speak to our analyst for a discussion on the above findings, click Speak to Analyst

Frequently Asked Questions (FAQs):

Key questions addressed in the report

What are the factors driving the growth of the Coated abrasive market?

The growing construction market and automotive.

What are the major applications for Coated abrasive?

The major applications of Coated abrasive are construction, automotive, and woodworking.

Who are the major manufacturers of Coated abrasive?

SAINT-GOBAIN (France), 3M (US), ROBERT BOSCH GMBH (Germany), FUJIMI INCORPORATED (Japan), ASAHI DIAMOND INDUSTRIAL CO. LTD (Japan), CABOT MICROELECTRONICS CORPORATION (US) are the key players in the global Coated abrasive market.

What are the reasons behind Coated abrasive gaining market share?

Coated abrasive are gaining market share due to increasing demand from the Asia Pacific region.

Which is the largest region in the Coated abrasive market?

Asia Pacific is the largest region in the Coated abrasive market.

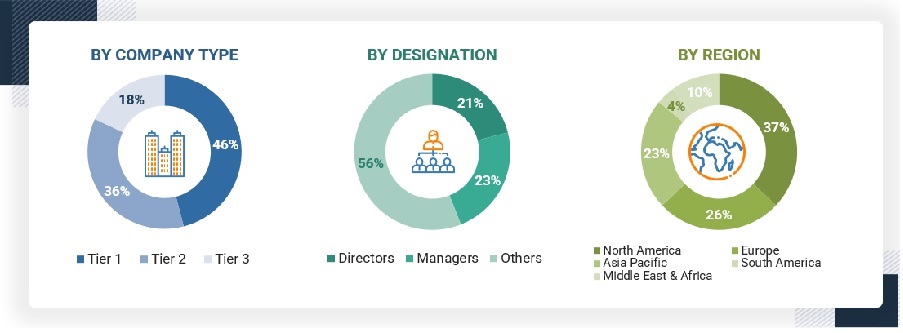

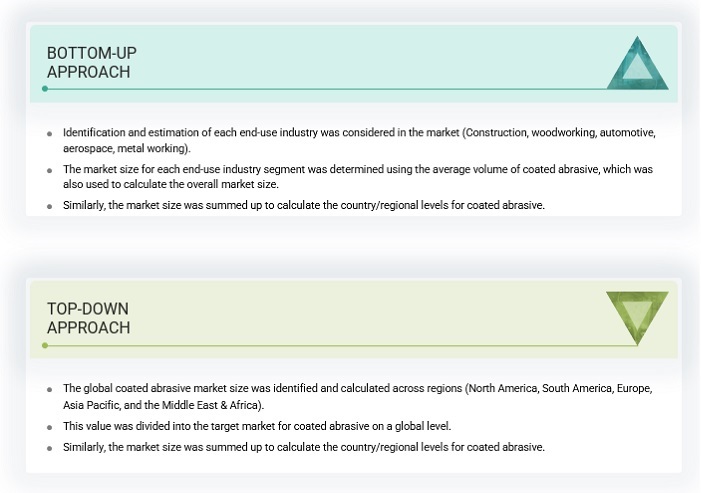

The study involved four major activities in order to estimating the current size of the Coated Abrasive market. Exhaustive secondary research conducted to gather information on the market. The next step was to conduct primary research to validate these findings, assumptions, and sizing with the industry experts across the value chain. Both top-down and bottom-up approaches were used to estimate the total market size. The market size of segments and subsegments was then estimated using market breakdown and data triangulation.

Secondary Research

Secondary sources include annual reports of companies, press releases, investor presentations, white papers, articles by recognized authors, and databases, such as D&B, Bloomberg, and Factiva; and publications and databases from associations, including Abrasive Products Manufacturers Association (APMA), Coated Abrasives Manufacturers Association (CAMA), European Abrasive Federation (FEPA), National Institute for Occupational Safety and Health (NIOSH), International Abrasives Association (IAA).

Primary Research

Extensive primary research was carried out after gathering information about coated abrasive market through secondary research. In the primary research process, experts from the supply and demand sides have been interviewed to obtain qualitative and quantitative information and validate the data for this report. Questionnaires, emails, and telephonic interviews were used to collect primary data. Primary sources from the supply side include industry experts, such as chief executive officers (CEOs), vice presidents (VPs), marketing directors, technology and innovation directors, and related key executives from various key companies and organizations operating in the coated abrasive market. Primary interviews were conducted to elicit information such as market statistics, revenue data collected from the products and services, market breakdowns, market size estimations, market forecasting, and data triangulation. Primary research also assisted in comprehending the various trends associated to type, applications, end – use industry, and region.

The breakup of Primary Research:

To know about the assumptions considered for the study, download the pdf brochure

COATED ABRASIVE MANUFACTURERS

|

COATED ABRASIVE MANUFACTURERS |

|

|

3M |

TYROLIT GROUP |

|

SAINT - GOBAIN |

JASON INCORPORATED |

|

ROBERT BOSCH GMBH |

ASAHI DIAMOND INDUSTRIAL CO., LTD |

|

FUJIMI INCORPORATED |

SIA ABRASIVES INDUSTRIES AG |

Market Size Estimation

The following information is part of the research methodology used to estimate the size of the Coated Abrasive market. The market sizing of the Coated Abrasive market was undertaken from the demand side. The market size was estimated based on market size for Coated Abrasive in various technology.

Global Coated Abrasive Market Size: Bottom-Up Approach and Top-Down Approach

To know about the assumptions considered for the study, Request for Free Sample Report

Data Triangulation

After arriving at the overall market size, the market has been split into several segments. To complete the overall market engineering process and arrive at the exact statistics for all segments, the data triangulation and market breakdown procedures have been employed, wherever applicable. The data was triangulated by studying various factors and trends from the demand and supply sides. Along with this, the market size was validated using both the top-down and bottom-up approaches.

Market Definition

The coated abrasive market comprises a wide range of products, such as sand page, grinding discs, and capable surfaces finishers and polishes in industrial areas like automotive, metalworking, woodwork, and construction. The demand created in the market would be better efficiency for surface treatment, enhancement in the quality of products, and better advancement in the abrasive materials that make them more precision and durable use.

Key Stakeholder

- End User

- Raw Material Suppliers

- Senior Management

- Procurement Department

Report Objectives:

- To define, describe, segment, and forecast the size of the Coated Abrasive market based on width, type, end – use industry, and region.

- To forecast the market size of segments with respect to various regions, including North America, Europe, Asia Pacific, South America, Middle East & Africa, along with major countries in each region

- To identify and analyze key drivers, restraints, opportunities, and challenges influencing the growth of the Coated Abrasive market

- To analyze technological advancements and product launches in the market

- To strategically analyze micromarkets, with respect to their growth trends, prospects, and their contribution to the market

- To identify financial positions, key products, and key developments of leading companies in the market

- To provide a detailed competitive landscape of the market, along with market share analysis

- To provide a comprehensive analysis of business and corporate strategies adopted by the key players in the market

- To strategically profile key players in the market and comprehensively analyze their core competencies

Available Customizations:

MarketsandMarkets offers the following customizations for this market report:

- Additional country-level analysis of the Coated Abrasive market

- Profiling of additional market players (up to 5)

Product Analysis

- Product matrix, which gives a detailed comparison of the product portfolio of each company in the Coated Abrasive market

Growth opportunities and latent adjacency in Coated Abrasive Market