Carbon Fiber Tube Market by Fabric Type (Unidirectional, Woven, Braided), Resin Type (Epoxy, Polyurethane, Other Resins) Manufacturing Process (Filament Winding, Pultrusion, Roll-Wrapping), End-Use Industry (Aerospace & Defense, Automotive, Sporting Goods, Medical, Other Industries), and Region - Forecast to 2029

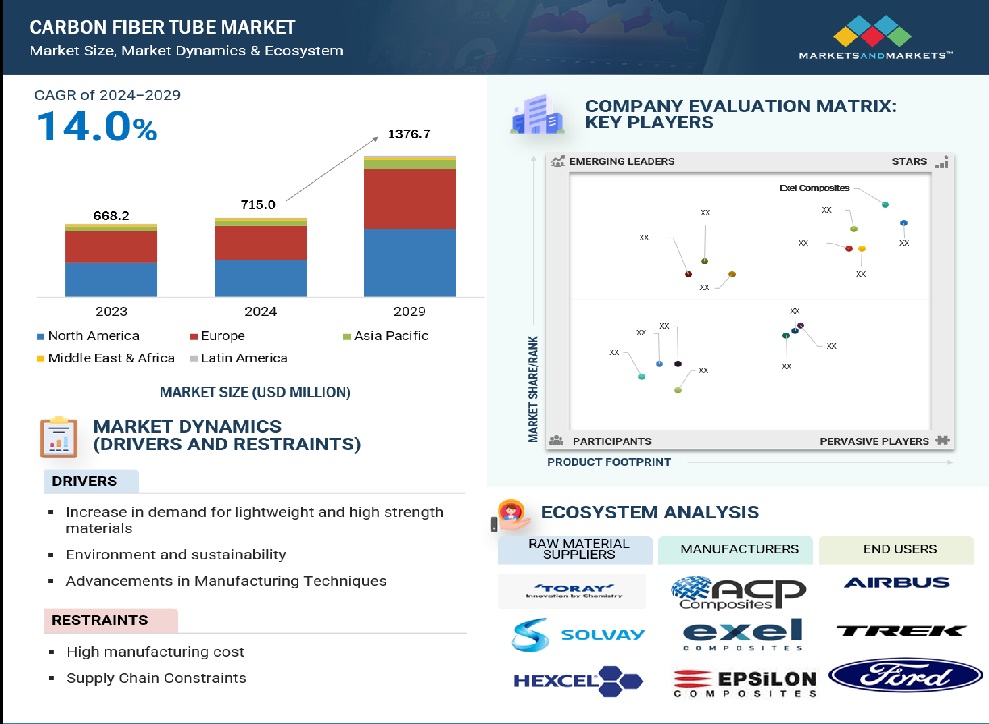

The carbon fiber tube market is estimated to be around USD 715.0 million in 2024 and is projected to reach USD 1376.7 million by 2029, at a CAGR of 14.0% from 2024 to 2029. Carbon fiber tubes, made from carbon fiber reinforced polymer composites, are used in industries like aerospace, automotive, sports, medical, and construction due to their lightweight and durable properties. These tubes are ideal for applications requiring a high strength-to-weight ratio, such as aircraft and high-performance vehicles. The increasing demand for advanced materials is driving the growth of the carbon fiber tube market. Their use in reducing weight enhances fuel efficiency and performance, especially in aerospace and automotive sectors. Additionally, their high strength-to weight ratio and durability align with growing sustainability goals, further promoting adoption across various industries focused on improving performance and reducing environmental impact.

Attractive Opportunities in the Carbon Fiber Tube Market

To know about the assumptions considered for the study, Request for Free Sample Report

Global Carbon Fiber Tube Market Dynamics

DRIVER: Increased demand for fuel efficiency in aerospace industry

The increasing demand for lightweight, high-strength materials is a key driver in the growth of the carbon fiber tube market. As industries such as aerospace, automotive, and sporting goods focus on improving fuel efficiency, performance, and sustainability, carbon fiber tubes offer an ideal solution due to their exceptional strength-to-weight ratio. In aerospace, reducing the weight of aircraft components enhances fuel efficiency and overall performance, making carbon fiber tubes highly sought after. Similarly, in the automotive industry, carbon fiber tubes are used in high-performance vehicles and electric cars to reduce weight, boost fuel economy, and improve handling. With environmental concerns pushing industries toward more sustainable materials, carbon fiber tubes, known for their lightweight and long-lasting properties, are increasingly favored, further accelerating market growth.

RESTRAINT: High material cost

The high raw material cost remains a key restraint in the carbon fiber tube market. Producing carbon fiber involves expensive processes, including the use of precursor materials like polyacrylonitrile (PAN), which are costly to manufacture and process. Additionally, specialized manufacturing techniques, such as filament winding and resin infusion, contribute to high production costs. This makes carbon fiber tubes significantly more expensive than traditional materials like steel and aluminum, limiting their widespread adoption, especially in price-sensitive industries. Sectors such as automotive and sporting goods, where cost-efficiency is a major concern, are particularly impacted by this cost barrier. While industries like aerospace and high-performance applications can justify the expense due to the material's superior performance and weight-saving benefits, other industries may be reluctant to invest.

Opportunity: Growing adoption of electric vehicles

The growing adoption of electric vehicles (EVs) presents a significant opportunity for the carbon fiber tube market. As EV demand rises, manufacturers aim to reduce vehicle weight to improve efficiency and range. Carbon fiber tubes, with their superior strength-to-weight ratio, are ideal for lightweight structural components like chassis, Propeller shaft, frames, and exhaust pipe. By reducing weight, these tubes enhance vehicle performance, energy efficiency, and driving range. Additionally, carbon fiber’s recyclability and durability align with automakers' sustainability goals, further boosting its demand. As the EV market expands, the need for carbon fiber tubes is expected to grow, creating new opportunities in the automotive industry.

Challenge: Recycling Issues

Recycling carbon fiber tubes presents several challenges despite their environmental benefits. The main issue is separating the carbon fibers from the polymer matrix, as traditional methods like mechanical grinding can damage the fibers, reducing their quality for reuse in high-performance applications. Chemical and thermal recycling methods, which break down the matrix to recover fibers, are costly and energy intensive. Additionally, the lack of standardized processes and infrastructure for recycling carbon fiber composites hinders widespread adoption. Variations in resins and fibers used complicate the development of a universal solution, further limiting the efficiency and scalability of recycling methods.

Global Carbon fiber tube Market Ecosystem Analysis

The carbon fiber tube market ecosystem is characterized by a dynamic interplay of key players, including manufacturers, suppliers, and regulatory bodies, all driven by the increasing demand for lightweight and environment friendly materials in various end-use industries. Major aerospace manufacturers like Boeing and Airbus lead the market, utilizing advanced composite materials to enhance structural integrity and reduce emissions, while suppliers such as Teijin and Toray provide essential raw materials like carbon fibers and resins. The market is further supported by technological advancements in manufacturing processes, such as automated fiber placement, which improve production efficiency and precision. Additionally, stringent environmental regulations and a growing emphasis on sustainability are pushing the industry towards greater adoption of composites across various applications, including commercial and military aircraft. This ecosystem is marked by collaboration between companies and research institutions to innovate and meet the evolving needs of the aviation sector, ensuring robust growth in the coming years.

Based on the Fiber type, woven carbon fiber tubes accounted for the largest market share in the carbon fiber tube market, in 2023.

Woven carbon fiber tubes are highly versatile, offering strength and stiffness across multiple directions, making them ideal for a variety of applications. They are commonly used in bicycle frames, automotive components, and industrial settings due to their durability and resistance to impact. These tubes are favored for their balanced properties, which provide optimal performance in demanding environments. There are several types of woven patterns, each with unique characteristics, including twill weave, satin weave, basket weave, leno weave, and mock leno weave. Twill weave tubes are often chosen for their visual appeal and are popular in high-end automotive parts, while basket weave tubes are known for their strength and are commonly used in heavy-duty construction applications. Each weave type offers specific advantages, making woven carbon fiber tubes a preferred material for projects requiring both strength and aesthetic appeal.

Based on the manufacturing process, the filament winding segment is accounted the highest market share in 2023, in the carbon fiber tube market.

Filament winding involves winding continuous carbon fibers around a rotating mandrel in precise patterns to create tubes with exceptional strength and stiffness. This technique is ideal for aerospace and industrial applications, as the winding patterns can be tailored to enhance the tube’s mechanical properties, ensuring it meets specific performance requirements. Known for its efficiency, filament winding produces tubes with excellent structural integrity and uniformity. The process can be automated, enabling high-volume production with consistent quality. Computer-controlled winding machines further enhance precision and repeatability, minimizing defects and ensuring reliable outcomes. Filament winding is especially advantageous for manufacturing large-diameter tubes, such as those used in rocket motor casings, pressure vessels, and large structural components in wind turbines.

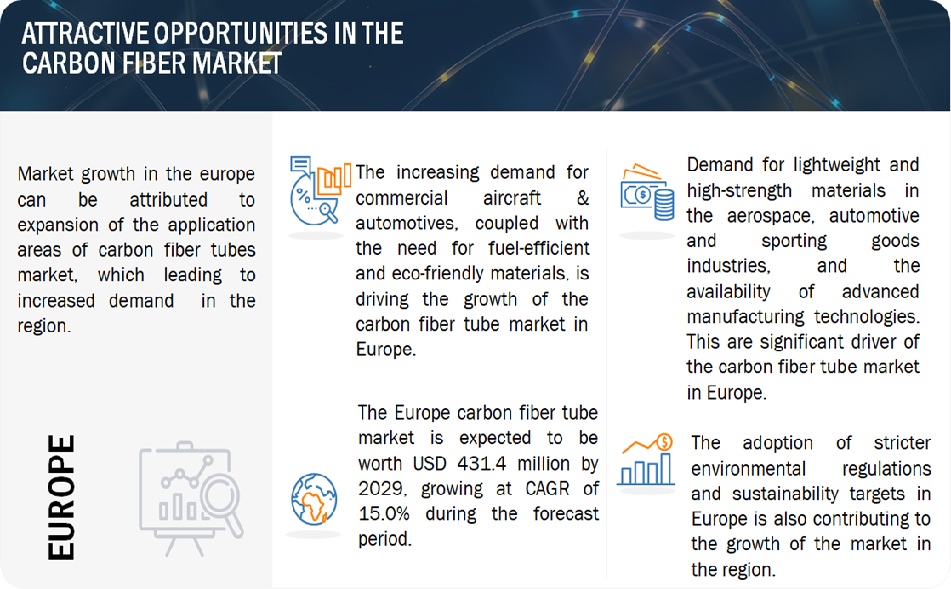

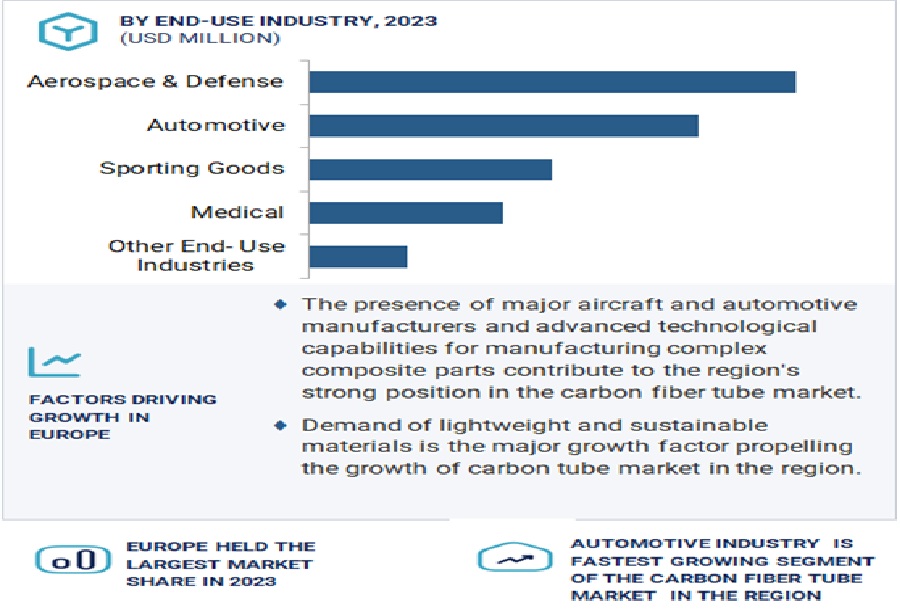

Europe region holds the largest share of the carbon fiber tube market

The European region presents significant growth opportunities for carbon fiber tubes, driven by increasing demand for lightweight, high-performance materials in industries such as automotive, aerospace, and sports equipment. As European automakers focus on reducing carbon emissions and enhancing fuel efficiency, the adoption of carbon fiber tubes in electric vehicles (EVs) and traditional cars is accelerating. Moreover, the European Union's strict environmental regulations are pushing manufacturers to adopt sustainable solutions, further boosting the demand for carbon fiber-based components. The aerospace sector in Europe is also a key contributor, with carbon fiber tubes being used in aircraft structures to reduce weight and improve fuel efficiency. Additionally, the growing emphasis on renewable energy and high-performance sports gear opens new markets for carbon fiber tubes. With ongoing technological advancements and the EU's commitment to green manufacturing, the carbon fiber tubes market in Europe is poised for substantial growth in the coming years.

To know about the assumptions considered for the study, download the pdf brochure

Key Market Players

- Exel Composites (Finland)

- Shanghai Metal Corporation (China)

- Goodwinds Composites LLC (USA)

- Carbon Light Private Limited (India)

- DragonPlate (US)

- ACP Composites, Inc. (US)

- Easy Composites Ltd (UK)

- NitPro Composites (India)

- Carbon Fibre Profiles Ltd (UK)

- C-Tech Ltd. (India)

- Refitech Composite Solutions (The Netherlands)

- ADENTE Advanced Engineering Technologies (Istanbul)

- EPSILON Composite (France)

- R&G Faserverbundwerkstoffe GmbH (Germany)

- Clearwater Composites, LLC (US)

Recent Developments of Carbon Fiber Tube Market

- In March 2021, Refitech has expanded its RefiFLEX carbon fiber square tube range, now offering a 40 x 40-millimeter high-precision tube with a standard length of 1,600 millimeters, along with the matching RefiFLEX 40S connectors. Additionally, Refitech supplies CarboSix (Mondovì, Italy) unidirectional (UD) carbon fiber pultrusion profiles to customers in the Benelux region. These profiles feature integrated mounting slots, allowing for frame construction with screws rather than glue, offering flexibility with different fixing materials. This expansion enhances Refitech’s offerings for precision construction in a variety of industries

- In October 2020, Refitech has introduced the ultra-compact and lightweight RefiFLEX TS pole22, a telescopic tube designed for audiovisual and hospitality applications. Weighing under 200 grams and measuring just 50 centimeters when retracted, this four-piece pole can extend smoothly up to 150 centimeters. Its compact size allows it to easily fit into a backpack, making it perfect for carrying microphones for reporters or vloggers. Additionally, the pole is ideal for passing medical or other equipment between socially distanced workers in both the hospitality and healthcare industries.

- In April 2019, Element 6 Composites has developed patent-pending techniques for manufacturing carbon-fiber tubes that provide optimal stiffness along each bending axis. These tubes offer resistance to bending similar to I-Beams, while maintaining the high torsional stiffness typically found in standard tubes.

To speak to our analyst for a discussion on the above findings, click Speak to Analyst

Frequently Asked Questions (FAQ):

What are the opportunities in the carbon fiber tube market?

Growing adoption of electric vehicles, increasing demand of drones and robotics, and technological advancements is propelling the growth of carbon fiber tube market during the forecast period.

Define the Carbon Fiber Tube Market.

Carbon fiber tubes are high-performance composite materials known for their exceptional strength-to-weight ratios, durability, and versatility. Made from carbon fibers embedded in a polymer matrix, CFRP tubes outperform traditional materials such as steel and aluminum in terms of strength and performance.

Which region is expected to have the largest market share in the Carbon Fiber Tube Market?

Europe’s carbon fiber tube market has been experiencing growth and significant industry demand. Europe is home to several prominent aerospace & automotive companies, and new aircraft projects, all contributing to the increasing adoption of carbon fiber tube products.

What are the major market players covered in the report?

Some of the key players in the carbon fiber tube market are Exel Composites (Finland), Shanghai Metal Corporation (China), Goodwinds Composites LLC (USA), Carbon Light Private Limited (India), DragonPlate (US), ACP Composites, Inc. (US), Easy Composites Ltd (UK), NitPro Composites (India), Carbon Fibre Profiles Ltd (UK), C-Tech Ltd. (India), Refitech Composite Solutions (The Netherlands), and ADENTE Advanced Engineering Technologies (Istanbul). Partnerships and deals were the key strategies adopted by these companies to strengthen their position in the carbon fiber tube market.

How big is the global Carbon Fiber Tube Market today?

The carbon fiber tube market is estimated to be around USD 715.0 million in 2024 and is projected to reach USD 1376.7 billion by 2029, at a CAGR of 14% from 2024 to 2029.

Carbon Fiber Tube Market

Growth opportunities and latent adjacency in Carbon Fiber Tube Market