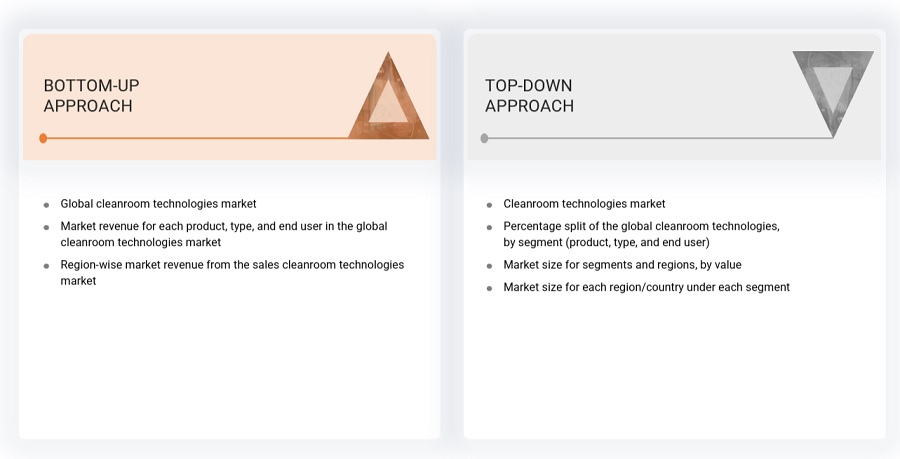

This study involved four major activities in estimating the size of the cleanrooms technologies market. Exhaustive secondary research was done to collect information on the market, peer market, and parent market. The next step was to validate these findings, assumptions, and sizing with industry experts across value chains through primary research. The bottom-up approach was employed to estimate the overall market size. After that, market breakdown and data triangulation were used to estimate the market size of segments and sub-segments.

Secondary Research

The secondary research process involved the widespread use of secondary sources, directories, databases (such as Bloomberg Businessweek, Factiva, and D&B Hoovers), white papers, annual reports, company house documents, investor presentations, and SEC filings of companies. Secondary research was used to identify and collect information useful for the extensive, technical, market-oriented, and commercial study of the cleanroom technologies market. It was also used to obtain important information about the key players and market classification and segmentation according to industry trends to the bottom-most level, and key developments related to market and technology perspectives. A database of the key industry leaders was also prepared using secondary research.

Primary Research

In the primary research process, various sources from both the supply and demand sides were interviewed to obtain qualitative and quantitative information for this report. The primary sources from the supply side include industry experts such as CEOs, vice presidents, marketing and sales directors, technology & innovation directors, and related key executives from various key companies and organizations operating in the cleanroom technologies market. The primary sources from the demand side included industry experts, purchase & sales managers, doctors, and personnel from research organizations. Primary research was conducted to validate the market segmentation, identify key players in the market, and gather insights on key industry trends and key market dynamics.

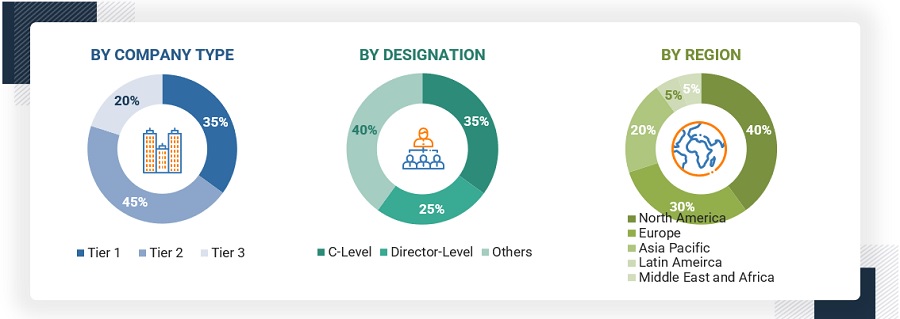

Breakdown of Primary Interviews

Note 1: C-level primaries include CEOs, COOs, CTOs, and VPs.

Note 2: Other primaries include Others include sales managers, marketing managers, and product managers.

Note 3: Companies are classified into tiers based on their total revenue. As of 2020: Tier 1=>USD 1 billion, Tier 2 = USD 500 million to USD 1 billion, Tier 3=<USD 500 million

To know about the assumptions considered for the study, download the pdf brochure

The research methodology used to estimate the size of the cleanroom technologies market includes the following details.

The market sizing of the market was undertaken from the global side.

Country-level Analysis: The size of the cleanroom technologies market was obtained from the annual presentations of leading players and secondary data available in the public domain. The share of products and services in the overall cleanroom technologies market was obtained from secondary data and validated by primary participants to arrive at the total cleanroom technologies market. Primary participants further validated the numbers.

Geographic market assessment (by region & country): The geographic assessment was done using the following approaches:

Approach 1: Geographic revenue contributions/splits of leading players in the market (wherever available) and respective growth trends

Approach 2: Geographic adoption trends for individual product segments by end users and growth prospects for each of the segments (assumptions and indicative estimates validated from primary interviews)

At each point, the assumptions and approaches were validated through industry experts contacted during primary research. Considering the limitations of data available from secondary research, revenue estimates for individual companies (for the overall cleanroom technologies market and geographic market assessment) were ascertained based on a detailed analysis of their respective product offerings, geographic reach/strength (direct or through distributors or suppliers), and the shares of the leading players in a particular region or country.

Global Cleanroom technologies Size: Top-Down and Bottom Up Approach

To know about the assumptions considered for the study, Request for Free Sample Report

Data Triangulation

After arriving at the overall market size—using the market size estimation processes explained above—the market was split into several segments and sub-segments. To complete the overall market engineering process and arrive at the exact statistics of each market segment and subsegment, data triangulation, and market breakdown procedures were employed, wherever applicable. The data was triangulated by studying various factors and trends from both the demand and supply sides.

Market Definition

Cleanroom technologies are specialized systems, processes, and equipment designed to produce an environment with low concentrations of airborne particulates, contaminants, and pollutants. Such technologies have significant applications in industries including pharmaceuticals, biotechnology, electronics, and aerospace, where a minute contaminant might compromise product quality or safety. Cleanroom technologies include such things as air filtration with HEPA and ULPA, environmental control for temperature, humidity, and pressure, and advanced monitoring systems that could be instituted in order to ensure particular standards of cleanliness are met, for instance ISO and GMP.

Key Stakeholders

-

Indian Pharmaceutical Association (IPA)

-

Pharmaceutical Research and Manufacturers of America (PhRMA)

-

European Federation of Pharmaceutical Industries and Associations (EFPIA)

-

Central Drugs Standard Control Organization (CDSCO)

-

India Brand Equity Foundation (IBEF)

-

Pharma & Biopharma Outsourcing Association (PBOA)

-

Indian Drug Manufacturers’ Association (IDMA)

-

World Health Organization (WHO)

-

Organization for Economic Co-operation and Development (OECD)

-

National Institutes of Health (NIH)

-

Centers for Disease Control and Prevention (CDC)

-

Annual Reports/SEC Filings, Investor Presentations, and Press Releases of Key Players

-

White Papers, Journals/Magazines, and News Articles

-

Paid Databases, such as Factiva, D&B Hoovers, and Bloomberg Business

Report Objectives

-

To define, describe, segment, and forecast the cleanroom technologies market by product, type, end user, and region

-

To provide detailed information about the factors influencing the market growth (such as drivers, restraints, opportunities, and challenges)

-

To analyze micromarkets1 with respect to individual growth trends, prospects, and contributions to the overall cleanroom technologies market

-

To analyze market opportunities for stakeholders and provide details of the competitive landscape for key players

-

To forecast the size of the cleanroom technologies market in five main regions (along with their respective key countries), namely, North America, Europe, the Asia Pacific, Latin America, and the Middle East & Africa

-

To profile the key players in the cleanroom technologies market and comprehensively analyze their core competencies2 and market shares

-

To track and analyze competitive developments such as acquisitions, product launches, expansions, collaborations, agreements, partnerships, and R&D activities of the leading players in the cleanroom technologies market

-

To benchmark players within the cleanroom technologies market using the competitive leadership mapping framework, which analyzes market players on various parameters within the broad categories of business strategy, market share, and product offering

Available Customizations

With the given market data, MarketsandMarkets offers customizations as per the company’s specific needs. The following customization options are available for the report:

Geographic Analysis

-

Further breakdown of the Rest of Asia Pacific veterinary surgical procedures market into Indonesia, Philippines, Vietnam, Hong Kong, and other countries

-

Further breakdown of the Rest of Europe veterinary surgical procedures market into Belgium, Russia, the Netherlands, Switzerland, and other countries.

-

Further breakdown of the Rest of Latin America veterinary surgical procedures market into Argentina, Peru, and other countries

Andrea

Mar, 2022

I want detailed information on the recent developments in the global Cleanroom Technologies Market.

Terry

Mar, 2022

Which product segment is accounting for the largest share of the global Cleanroom Technologies Market?.

Ann

Mar, 2022

Which factors are proving to be the game changer for the global growth of Cleanroom Technologies Market?.